How product traceability can be used to improve your performance?

From barcodes to RFID chips, companies now have a wide range of technologies available to identify the provenance of a product and track it at every stage of its journey, from the production plant to its final destination.

The traceability of goods naturally plays an essential role in the event of a dispute or a health or regulatory problem. Smartly exploited, it also represents a tool of choice for improving your logistics management and building customer loyalty.

After a brief review of the theory, this article looks at the main solutions available to optimise your processes and increase productivity.

Table of contents

- Tracking and tracing: 2 sides of the same issue

- A wide range of traceability solutions for your business

- The leading software for tracking goods and building customer loyalty

The product traceability is essential to improve the performance of a logistics company. Traceability software and solutions are being used successfully: QR codes, SKU codes, RFID products, ERP, WMS and transport software.

Tracking and tracing: 2 sides of the same issue

Traceability is a fairly recent concept in the United-Kingdom, originally developed to identify and track farm animals.

From the mad cow crisis to the coronavirus, the scope of traceability continues to expand in response to the anxieties of consumers who want to know and control everything.

The popularity of traceability can be explained by the widespread use of tools such as barcodes and RFID chips – which are far more efficient than paper documentation – but above all by the increasing complexity of the supply chain.

In a global system where each supply chain has an ever-increasing number of stages and intermediaries, traceability is essential for providing answers to customers and determining who is responsible in the event of a problem.

This is why some experts now distinguish between tracking and tracing.

Product traceability or tracing

This form of upstream tracing is essential to ensure the quality of a product, or conversely, to quickly identify the origin of a defective component or contaminated food.

Every day, for example, the website Food Standards Agency relays numerous recalls of dangerous products, spotted thanks to such tracing work.

Logistics traceability or tracking

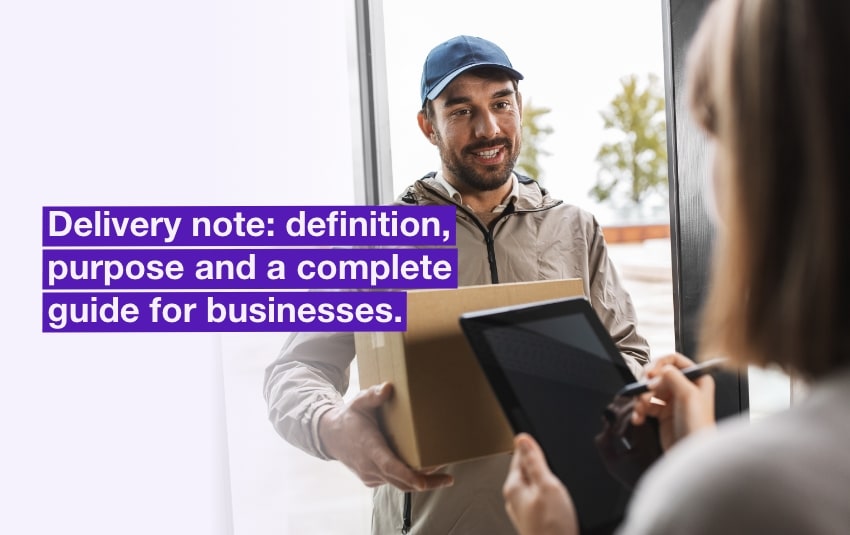

Tracking is essential for keeping track of the itinerary and location of a product or batch of goods, and therefore for estimating a delivery date to the end customer.

It can also be used to produce automated delivery reports or to follow the route of a parcel ordered online.

Logistics tracking makes it possible to follow the itinerary of a product to the end customer.

A wide range of traceability solutions for your business

To implement traceability in practice within your company, you need to find the tools to match the movement of goods in the real world with the data collected.

There are now many tracking solutions available to professionals, at increasingly attractive prices. Here’s a closer look at 5 technologies that have already proved their worth!

Barcodes

Scanned for the first time in 1974 on a packet of chewing gum in the United States, the barcode quickly invaded supermarket shelves and, more generally, the retail sector.

Managed by a single organisation, GS1, this 13-digit code makes it possible to identify each product at international level without any possible ambiguity. It is therefore a reference tool for speeding up the checkout process and facilitating stock management.

To read it, all you need is a suitable optical scanner. There are scanners available at all prices, from a few dozen euros for an entry-level scanner.

QR codes

A variant of the 2-dimensional barcode, the QR code is as easy to generate as it is to read, since all you need is a smartphone.

Its little black and white squares hide an excellent marketing solution, ideal for easily sharing the address of a website, a download link to a mobile application, and so on. But it’s also a great traceability tool, very useful for :

- Confirm information about a reservation or admission to a cinema or theatre.

- Get information on the origin, ingredients or allergens of a product, on a restaurant menu or packaging, etc.

The QR code is a very useful traceability tool for getting information about the origin of a product.

SKU codes

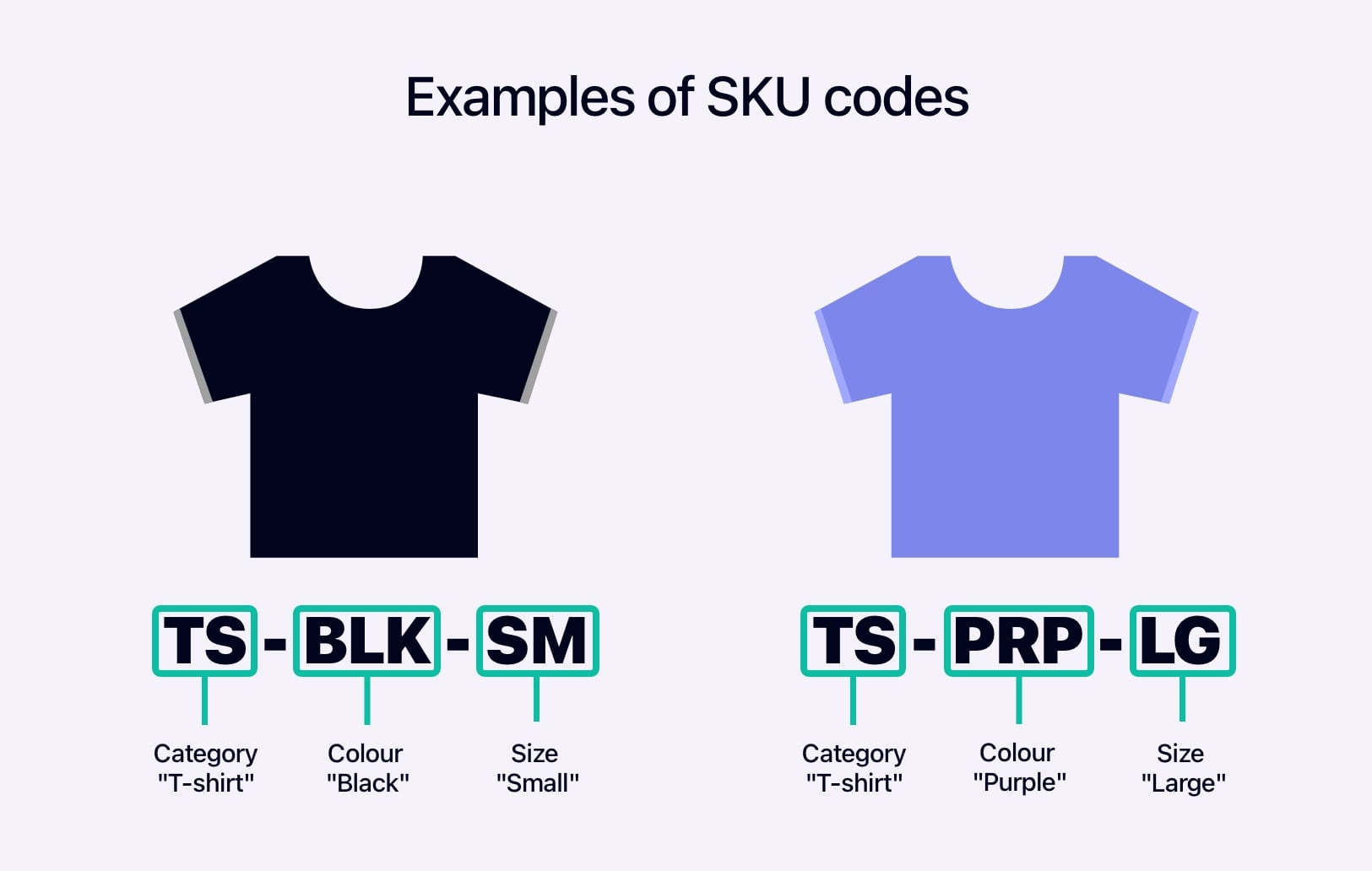

SKU (Stock Keeping Unit) codes are very similar to bar codes. But their function is very different.

With a length of 8 to 12 characters, SKU codes can be made up of letters and numbers, or just numbers. This is because, unlike the barcode, it is a warehouse reference for strictly internal use.

So it’s up to you and you alone to decide what these different characters mean. Depending on your needs, they can provide information about the brand, dimensions, weight or colour of the labelled product.

Used properly, these codes are invaluable for optimising the storage of goods in your warehouses. Thanks to SKU codes, for example, you can easily identify the products that are most in demand and position them in the most accessible locations to save time when dispatching goods.

A wide range of software can be used to create and manage such codes: warehouse management software, of course, but also certain e-commerce CMS such as Shopify.

SKU codes help to optimise the storage of goods in warehouses.

RFID products

RFID chips and tags are highly innovative devices capable of storing large quantities of information sent via radio frequency waves (RFID stands for Radio Frequency Identification).

Unlike previous systems, RFID tags can be read without a direct view. Let’s imagine, for example, that you want to track the shipment of 1,200 garments of various types (jumpers, jackets, etc.), spread over several pallets, in real time.

Thanks to RFID antennas and boxes placed close to the loading bays, you can know the exact number and contents of the boxes, while preserving their integrity, as you no longer have to open them!

Depending on your needs, RFID data can be stored on all types of supports: rigid or flexible labels, printable, single-use, etc. For added security, they can also be encrypted.

The only downside is that the systems that are powerful enough to meet the needs of logistics and transport professionals are still fairly expensive.

GPS and other connected solutions

Many objects connected to the cloud now enable businesses to collect and exchange data instantaneously, starting of course with our beloved smartphones.

Thanks to the GPS chip that comes as standard on mobiles and tablets, our customers can track their drivers’ routes in real time and automatically readjust the itinerary in the event of unforeseen circumstances, cancellations or accidents.

But many other objects can collect and transmit large quantities of information remotely, using Wi-Fi or the 4/5G network: this is the famous Internet of Things (IoT).

Some companies are able to connect all kinds of products to optimise your business processes:

- Tippers to rationalise waste collection.

- On-board units in vehicles to encourage eco-driving or facilitate fleet management.

- Gauges fitted with specific sensors to measure the level of fuel in a tank and prevent fuel theft, etc.

The leading software for tracking goods and building customer loyalty

There are now so many different systems for collecting data flows on goods that there is always a solution to suit your needs.

The real difficulty lies in choosing the right IT tools to analyse these huge quantities of information and turn traceability into a real competitive advantage.

Integrated management software (ERP)

ERP is a business software package designed to facilitate the flow of information between different departments (production, sales, human resources, accounting, etc.), thereby optimising business performance.

The best-known general-purpose ERPs include Odoo, Salesforce, Sage, Cegid and others.

These software packages are not specifically designed for logistics professionals. However, some of their features, such as Odoo’s warehouse management module, are very useful for improving traceability.

Some ERP systems, such as Odoo, can also connect to AntsRoute software to automatically exchange information on orders and proofs of delivery, for example.

Warehouse management software (WMS)

Unlike ERP systems, warehouse management software is specifically designed to meet the needs of professionals who want to monitor and optimise in real time all their inbound and outbound flows of goods.

Warehouse management software worthy of the name offers a wide range of functions for better management of the various logistics operations:

- Supply tracking

- Continuous stock updates

- Optimisation of storage and picking operations

- Real-time shipment control, etc.

Warehouse management software enables goods flows to be monitored and optimised in real time.

Transport management software (TMS)

In the transport software family, we mainly find:

- Fleet management software. These solutions are aimed primarily at companies with large fleets of vehicles, such as leasing companies and large transport and courier companies. This software enables you to monitor the location of drivers in real time, as well as optimising the costs associated with your fleet (purchase, leasing, maintenance, fuel consumption, etc.).

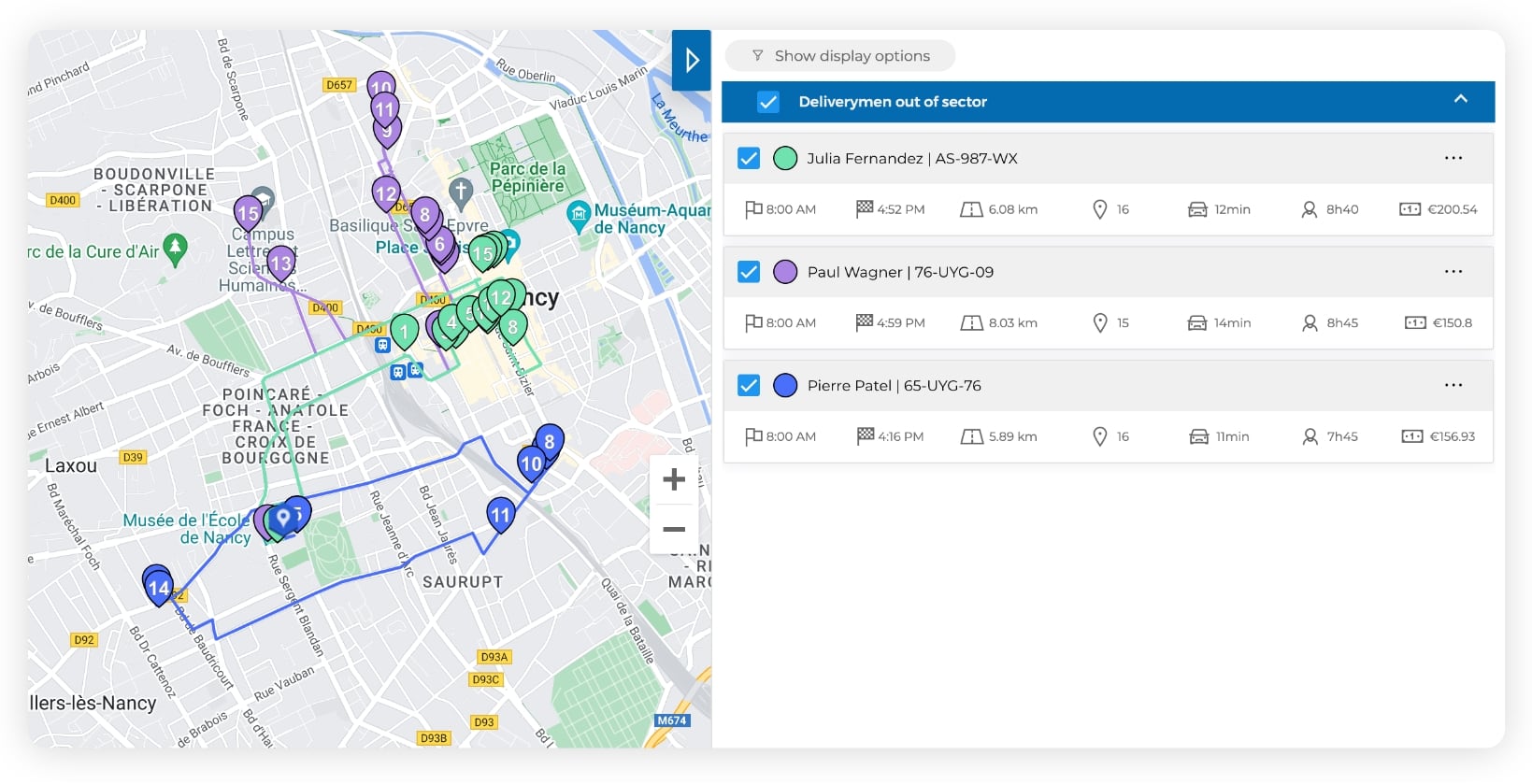

- Route optimisation software. These tools are designed to meet the needs not only of hauliers, but also of all professionals whose transport or delivery is an integral part of their service. With software like AntsRoute, for example, you can easily plan all your delivery routes and track their completion in real time.

Our solution can also help you improve the customer experience by sending personalised emails or text messages to let them know when the driver is due to arrive, or even track his arrival on a map!

The AntsRoute route optimisation software interface.

Would you like to find out more about the different IT solutions available to optimise your supply chain? This article gives you some valuable tips on how to choose your next warehouse management or route optimisation software package.

Free 7-day trial | No credit card required

Contenu

- Tracking and tracing: 2 sides of the same issue

- Product traceability or tracing

- Logistics traceability or tracking

- A wide range of traceability solutions for your business

- Barcodes

- QR codes

- SKU codes

- RFID products

- GPS and other connected solutions

- The leading software for tracking goods and building customer loyalty

- Integrated management software (ERP)

- Warehouse management software (WMS)

- Transport management software (TMS)