What is route optimisation?

Here are some key definitions of route optimisation to help you understand how software can be tailored to your business constraints and strategy.

Published on 4 May 2022 • Reading time: 8 min read

The route optimisation is a sophisticated logistics process whose objective is to build the best routes by optimising the use of a company’s resources. In other words, optimising a route consists of determining the best order for a list of locations to be visited, taking into account the vehicles and drivers availability, the skills required, and your specific business constraints.

After reminding some essential definitions of route optimisation, this article will help you to understand how optimisation software works. What are the tools used by these software applications to adapt to your constraints and your strategy in a given business or industry?

- Definition of a “route”.

- Difference between “ordering” and “route optimisation”.

- Definition of “route scheduling”.

- What are the objectives of route optimisation?

- How does route optimization software work?

What is a route?

A route is the itinerary traveled by a person or a vehicle from a starting point to return to the same point. Between the two points, this route is made of stops that correspond each time to an operation to be carried out:

- Visiting a customer or patient.

- Delivery, pickup or exchange of goods.

- Installation, maintenance, testing, sampling, etc.

The completion of each of these tasks usually is constrained by one or more factors, which depend on the business or industry concerned. These may include constraints such as:

- Specific skills of the field worker (licence, authorisation, technical expertise, etc.).

- Characteristics of the vehicle (engine, capacities, features, etc.).

- Requirements regarding the management of human resources, such as the duration of breaks, leaves and absence of employees, etc.

- The order in which some operations should be completed. For example, pickups before deliveries.

- A time constraint in the case of fresh products, fast-setting concrete, etc.

What is the difference between “ordering” and “route optimisation”?

The ordering is the process of organising tasks to be completed in a given order. For example, ordering is used if your company has only one delivery driver, and you order the customers to be visited to minimise the distance to be traveled.

But it can quickly become more complicated if you add one or more extra factors, such as:

- Fixed hours of visit.

- Reduced operating costs.

- The use of resources needed for the operations, such as spare parts to be picked up and installed during the same route.

It is called route optimisation. This term refers to generating routes from a cloud of locations to be visited, taking into account different constraints, such as:

- The visits or deliveries to be completed.

- The human resources available.

- The required equipment, etc.

… while trying to minimise the number of miles travelled! If a route is organised in this way, for example using a spreadsheet and navigation software, it is possible to find acceptable solutions in terms of time and constraints. Although the solution found may be sufficient in a given business, the optimisation of resources is often limited, and the organisation of the routes themselves can be very time-consuming.

What is “route scheduling”?

The planning adds another dimension to route optimisation.

In route building, the optimisation concerns a cloud of points, such as a list of customers to be delivered on a given day. In contrast, route scheduling is about extending the scope to analyse several clouds of points, and choosing only one. For example, is it better to visit this customer on this day or the next day?

At this level of complexity, the use of software becomes necessary. Only a dedicated software, a route optimisation software, is able to calculate precisely the consequences of each available choice, and to build the most efficient routes in the shortest time.

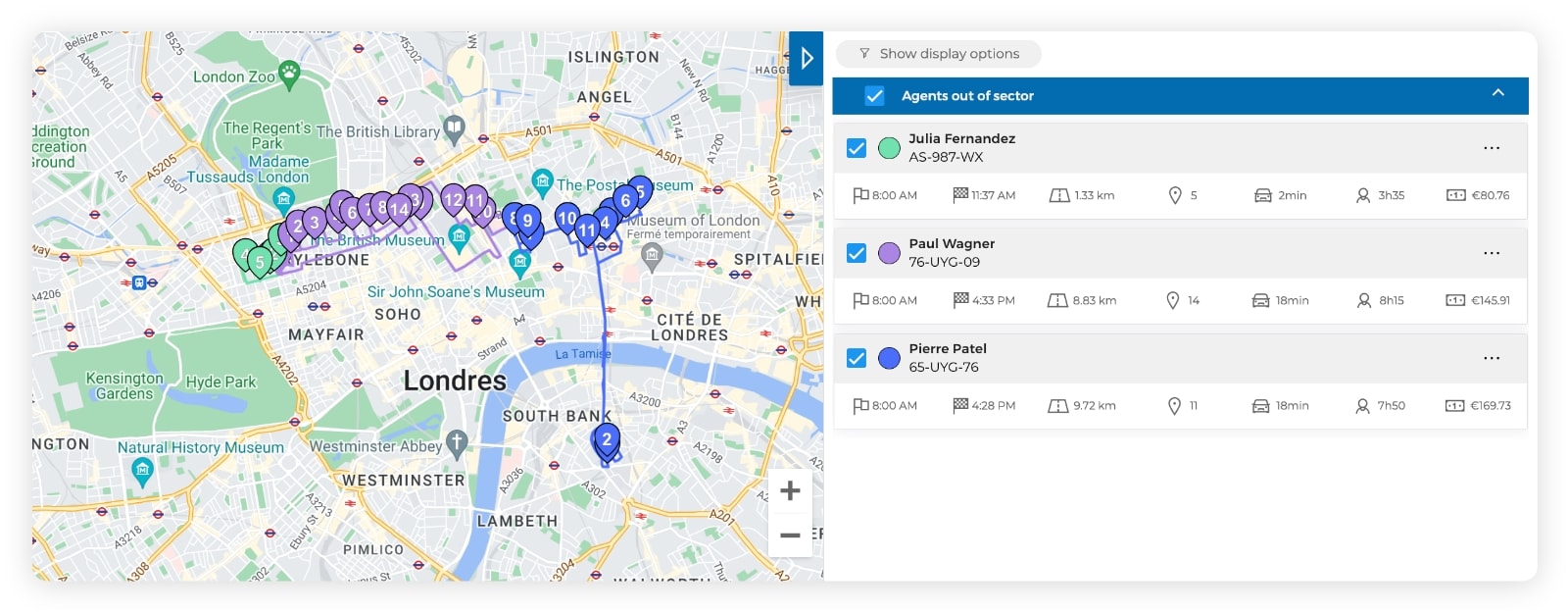

The optimisation software provides the results of its calculations in detailed route sheets, which can be printed out or displayed on a mobile application. The route map is the result of this optimisation work for a given day. It consists of the different routes to be completed by your workers.

The route plan on the AntsRoute software.

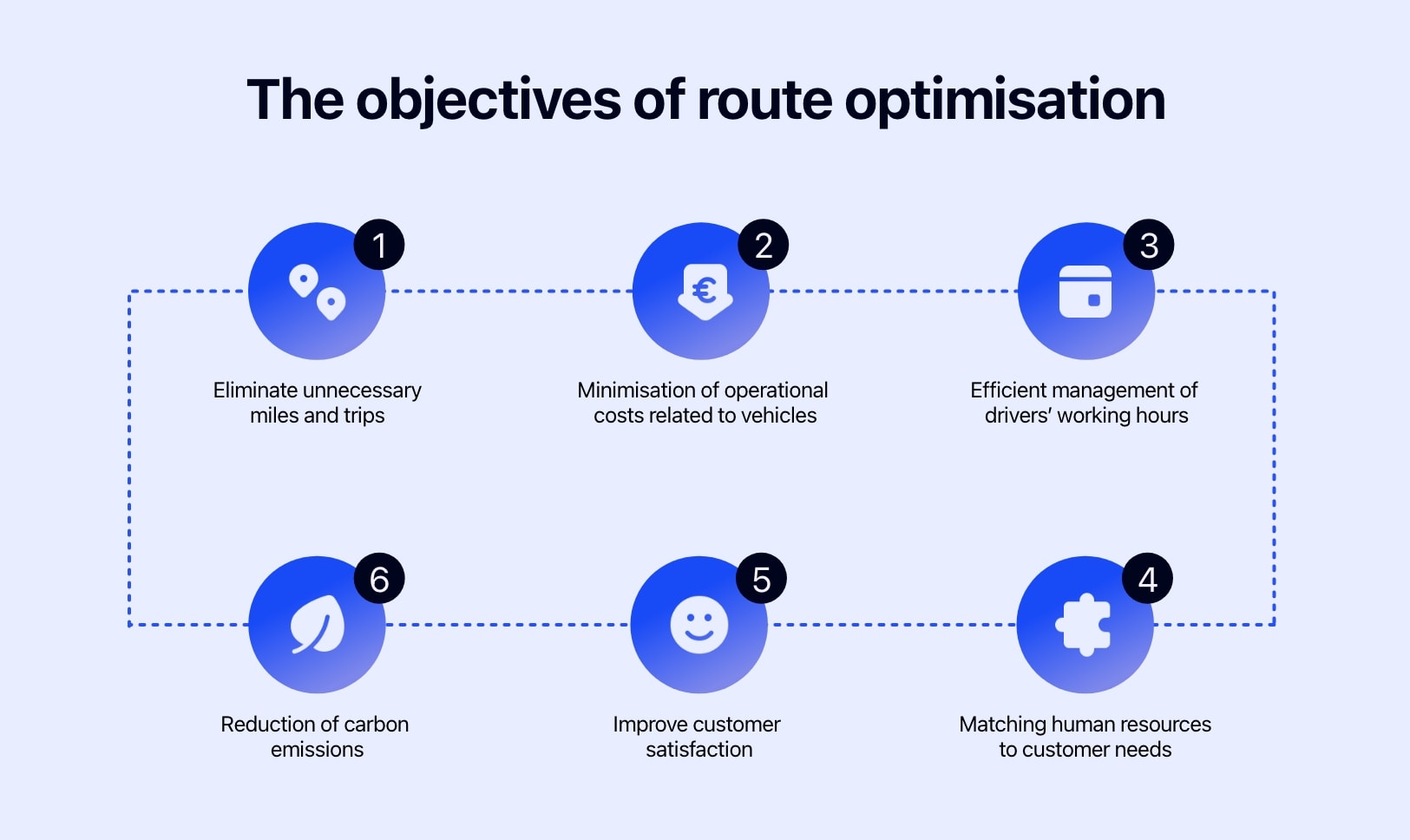

What are the objectives of route optimisation?

From one company to another, the challenges of route optimisation are never quite the same. The main objectives of the directors and logistics managers are:

- The reduction in travel time and unnecessary miles.

- The minimisation of the number of vehicles used and the associated operational costs (fuel, tolls, maintenance, etc.).

- A more efficient management of schedules, whether to meet legal constraints (working hours and rest periods, holidays, etc.) or customer requirements (opening or reception hours, contractual frequency of visits, etc.).

- A better match between available human resources and customer needs. For example, a company that specialises in maintenance must be sure to send a field worker with the required technical skills for each task.

- An improvement in the quality of service, and therefore in customer satisfaction.

- The decrease in CO2 emissions, etc.

The six main objectives of route optimisation.

How does route optimization software work?

There are many route optimisation software available on the market today. Some software is designed for general use, while others are tailored to one or more industries. However, all of them are based on the same technologies to ensure the best possible match between the human and material resources available and the tasks to be completed.

This article is not aimed at giving you a course in advanced computer science, but understanding the main principles of how route optimisation software works is very useful for choosing it and making the most of its capabilities!

Definition of your strategic objectives: the optimum

To optimise your routes in a relevant way, the software must “understand” what the best route looks like for you. However, the word “optimised” does not have the same meaning, depending on the person involved and the business. Therefore, it is necessary to indicate to the tool the optimum to be achieved and the constraints to be taken into account.

There are some optimums that are shared by several types of business or organisation. Among the most commonly required optimums, we find:

- The reduction of miles travelled by the vehicle fleet.

- The minimisation of used resources.

- The maximisation of the number of visits, field service operations or deliveries.

- The prioritisation of some types of operations. For example, a company working in the field of electrical appliances should give priority to urgent repair orders and the installation of new equipment. The schedules of the technicians will then be optimised by adding less urgent tasks.

The most sought-after optimums for route optimisation.

But you can also give the software more specific optimums, based on the economic, social or environmental objectives of your business. For example, a mission-driven company may determine that an optimal route is one that generates the lowest possible carbon dioxide emissions. In any case, a first analysis with our team is useful to ensure that the settings defined are perfectly in accordance with the optimum wanted from a mathematical point of view.

The algorithms, necessary tools to determine optimal routes

Once you have precisely defined the optimum you are looking for, the software runs its “optimisation engine” to calculate the best possible route, taking into account your business constraints. To achieve this, route optimisation software is based on a set of tools from the field of mathematics: the algorithms.

Although the word “algorithm” may be quite frightening, it actually describes something quite simple. In general terms, an algorithm can be defined as a sequence of instructions for solving a problem based on data provided by the user.

In everyday life, every time we carry out a step-by-step cooking recipe to make the best possible cake, we are using a kind of very simple algorithm. The same is true in computing, although this sequence of instructions is of course infinitely more complex!

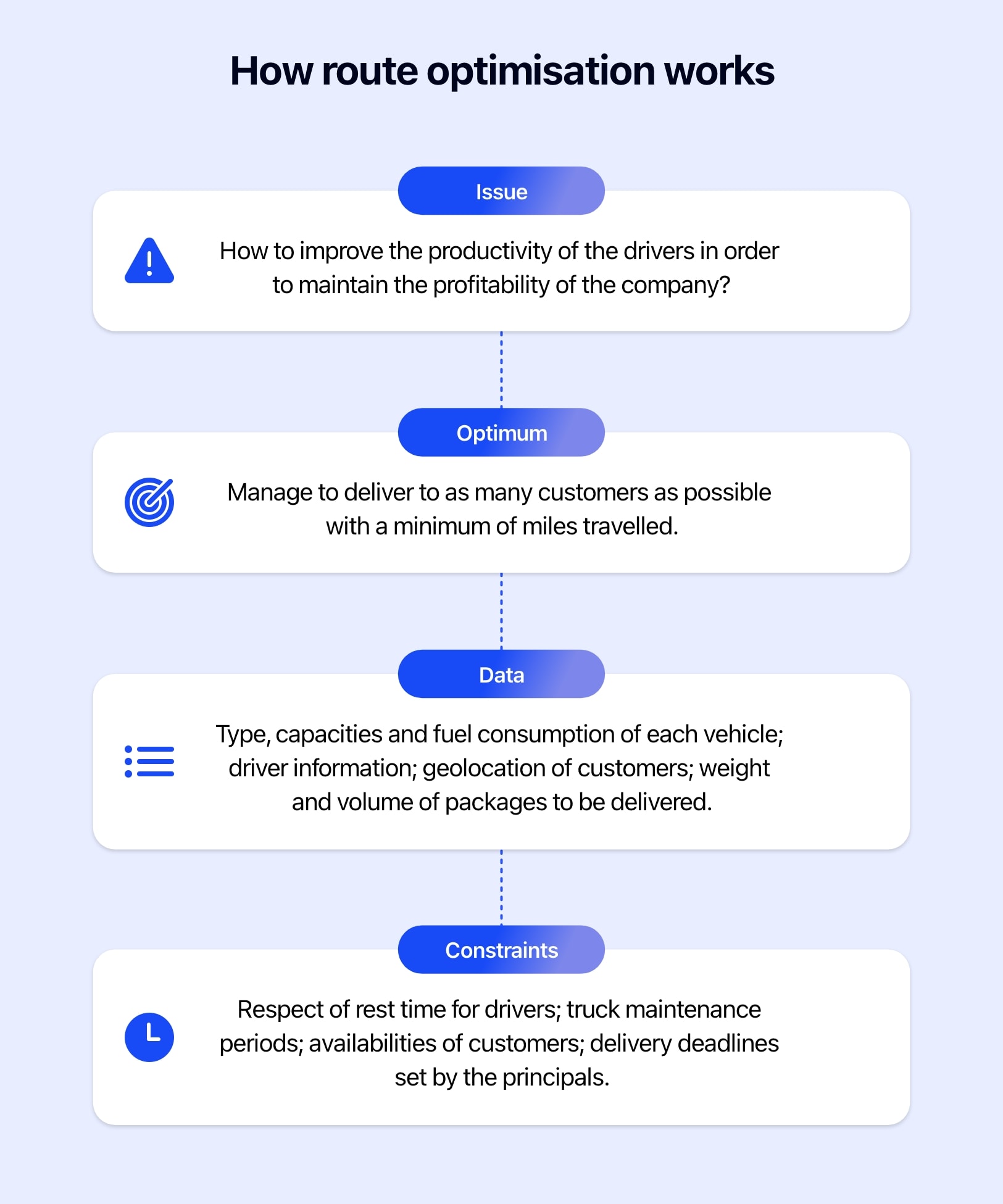

How route optimisation works.

In order to build the best possible route, the machine analyses, evaluates and mixes the data available, until it determines the route that is closest to the defined optimum.

To make things even more precise, let’s take the case of a transport company with very tight margins:

- Problem to be solved: how to improve the productivity of the drivers in order to maintain the profitability of the company?

- Optimum: manage to deliver to as many customers as possible with a minimum of miles travelled.

- Data provided by the company: type, capacities and fuel consumption of each vehicle; driver information such as licence; geolocation of customers; weight and volume of packages to be delivered.

- Constraints: respect of rest time for drivers; truck maintenance periods; hours of reception or presence of customers; delivery deadlines set by the principals.

As part of the optimisation, all these settings are “translated” into lines of code, so that they can be easily processed by the computer. The programme executes the same series of instructions as many times as necessary, and with each iteration the result gets a little closer to the optimum required here: cost-effective routes.

Algorithms adapted to each business problem

As you might imagine, the development of such algorithms quickly becomes very technical. Route optimisation software designers must also implement acceleration strategies to get an appropriate solution within reasonable time. But to make it simple, we can classify the algorithms used by our software into several categories:

- The ordering algorithms are useful if you have only one field worker.

- The algorithms used in the building of routes, which are much more complex, make it possible to process a group of locations to be visited while respecting a set of constraints.

- The algorithms designed for route scheduling, which are the most advanced, are able to handle a very large number of use cases in diverse industries. For example, routes over several days, major constraints regarding the sectorisation, large number of drivers or technicians, etc.

Although there is still much to be discovered in operations research, these solutions already guarantee complete route optimisation across the entire business process. The experts are therefore focusing on developing algorithms that can progressively improve the quality of the results without human input, which is commonly known as artificial intelligence.

Start the optimisation of your routes today

Free 7-day trial | No credit card required