At-home tyre and automotive glass replacement: garages move beyond the workshop (and optimisation becomes key)

Blog > Field Service > At-home tyre and automotive glass replacement: garages move beyond the workshop (and optimisation becomes key)

At-home tyre and automotive glass replacement: garages move beyond the workshop (and optimisation becomes key)

Published on 5 January 2026 • Reading time: 11 min read

At-home tyre and automotive glass replacement is booming. A windscreen chip on your way home from work? A flat tyre on a Monday morning just before a meeting? A commercial vehicle that absolutely must be back on the road at dawn? Now, it’s the garage that comes to the customer. Time savings, flexibility, no trip to the workshop: from the customer’s perspective, the service ticks all the boxes.

But behind this apparent simplicity, the reality on the ground is quite different. Technicians juggle sometimes endless travel times, onboard inventory to manage, unpredictable weather, seasonal demand peaks, and emergencies that arise without warning. In a business where everything can change from one minute to the next, how can routes be kept reliable, on time, and profitable? The answer comes down to one word: optimisation.

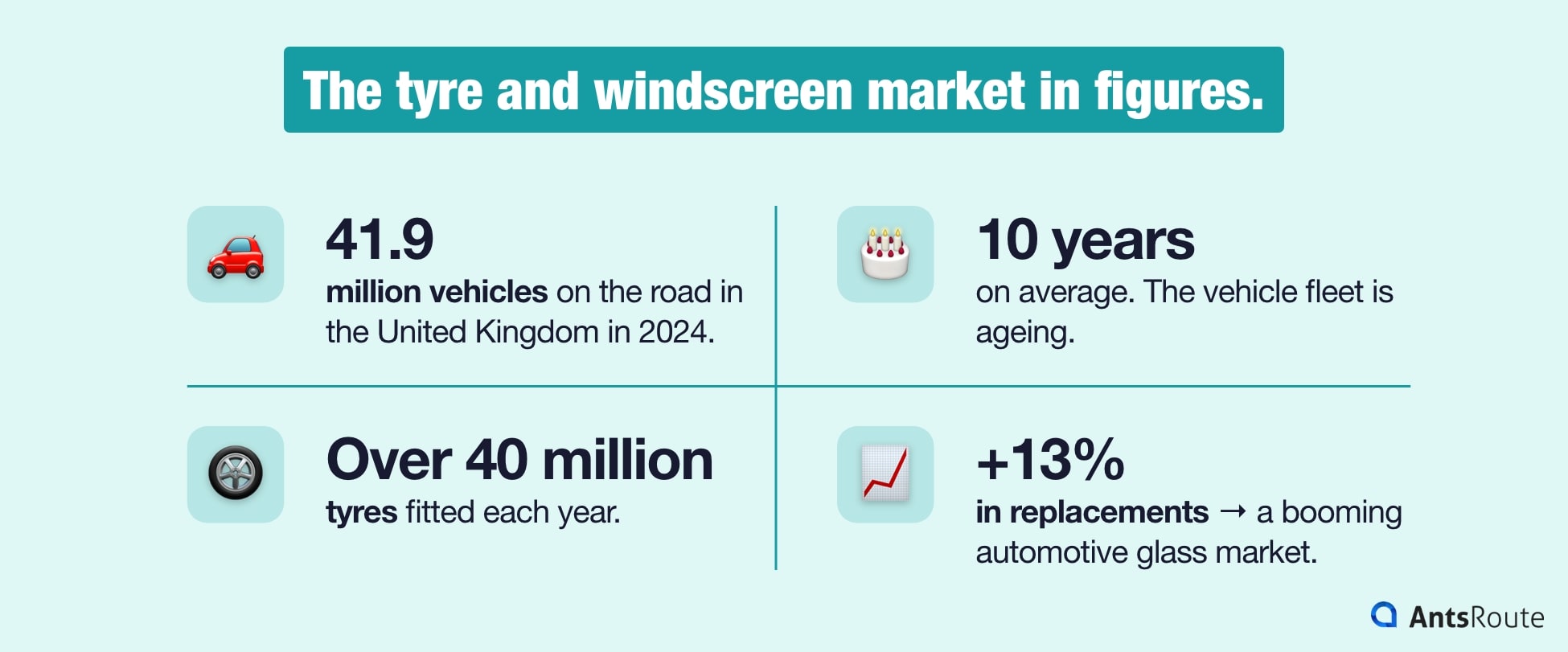

A few figures to put the scale of the sector into perspective:

- 41.9 million vehicles on the road in the United Kingdom in 2024

- An ageing vehicle fleet, with an average age of 10 years

- A booming automotive glass market (+13% in replacements in 2023 vs. 2022)

- Over 40 million tyres fitted each year

Table of contents:

- A rapidly changing market: when the garage comes to the customer

- Tyres and automotive glass: two key activities under pressure

- The constraints of mobile garages: complex logistics

- How AntsRoute optimises your routes and transforms your mobile operations

- 4 practical tips to successfully digitise your operations

☝️ Key takeaways

- At-home tyre and windscreen services are booming, but the logistics are far more complex (emergencies, weather, stock, routes, part references).

- Manual planning is reaching its limits: delays, errors, imprecise time slots and shrinking margins.

- Optimisation (AntsRoute) changes the game: fewer kilometres, reliable schedules, greater responsiveness and higher customer satisfaction.

A rapidly changing market: when the garage comes to the customer

Until just a few years ago, replacing a windscreen or changing tyres almost always meant a trip to the workshop. Today, the rules have changed. Much like food delivery or in-home services, motorists now expect professionals to come to them. The goal? To avoid immobilising their vehicle or disrupting their schedule.

The reality is clear: with an average age now exceeding 10 years, the British vehicle fleet has never been older. And the older vehicles get, the more frequent maintenance and repair work they require.

In practical terms, this means:

- More fragile windscreens, increasingly exposed to impacts

- Overstressed tyres, sometimes used beyond recommended limits

- A growing need for maintenance and repairs

The automotive glass market perfectly illustrates this trend: +13% in replacements and +4% in minor chip repairs in 2023 compared with 2022. Major networks, such as Autoglass, National Windscreens, and Auto Windscreens, operate more than 270 locations, but independent mobile players are carving out a strong position by focusing on ultra-local service.

As glass damage incidents continue to rise year after year, demand remains constant. The real challenge is no longer customer acquisition, but delivering the service at the right place, at the right time.

Tyres and windscreens: key market figures.

Tyres and automotive glass: two key activities under pressure

Highly technical operations under intense operational strain

Today’s windscreens are true concentrations of technology: cameras, ADAS sensors, driver-assistance systems—turning every replacement into a high-precision operation.

Implications for technicians:

- Longer service times

- Need for highly specialised skills

- Mandatory recalibration

- No room for improvisation

Add to this the impact of weather conditions (hail, frost, rain, wind, etc.), and demand can double within a matter of hours. Without the right tools to prioritise jobs, schedules can quickly spiral out of control.

On the tyre side, the picture is no simpler, driven by successive waves:

- The November rush for winter tyres

- Springtime fleet renewals

- Everyday puncture emergencies

Here too, the slightest disruption can force the entire route to be urgently reorganised.

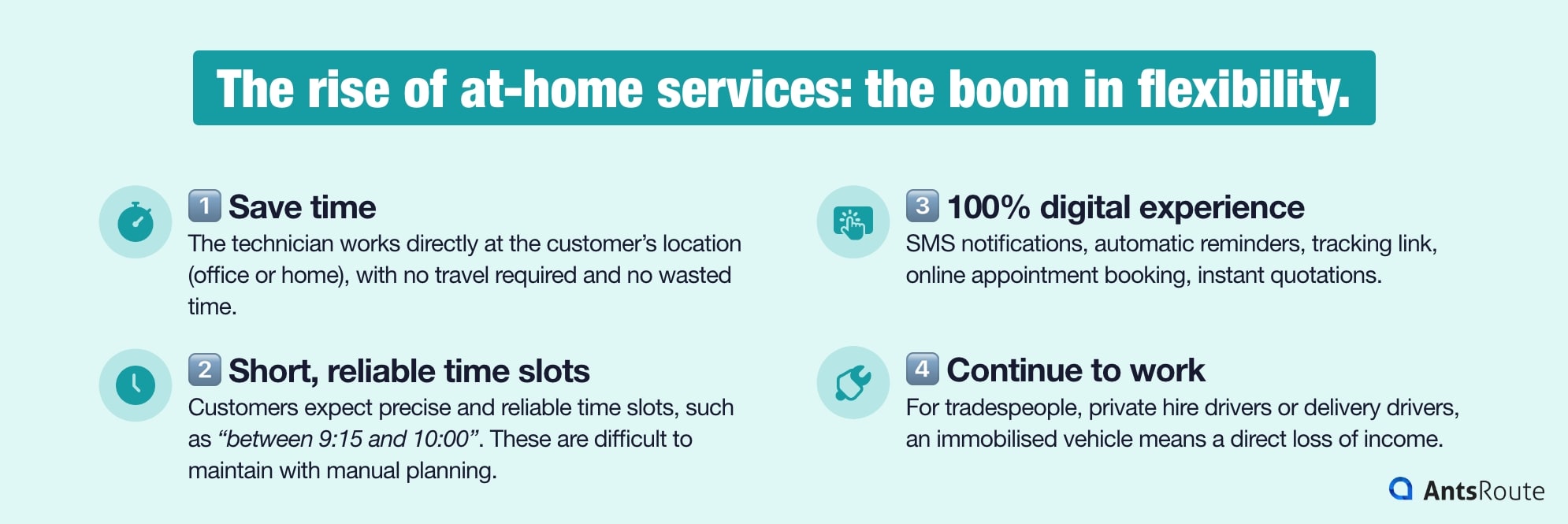

The rise of at-home service: flexibility takes centre stage

Why are motorists turning away from the workshop? Because the paradigm has shifted: today, the service comes to the customer. Expectations are clear:

- Save time: The technician comes to the office, the home, or even a supermarket car park. No more shuttles or hours wasted.

- Short, reliable time slots: Customers expect the same punctuality as an e-commerce delivery. They want an appointment “between 9:15 and 10:00,” not a vague window “between 8:00 and 12:00.” A (nearly) impossible challenge with manual planning.

- A 100% digital experience: SMS notifications, automatic reminders, tracking links, online booking, instant quotes—simplicity above all.

- Keep working: For tradespeople, ride-hail drivers, or delivery workers, a vehicle off the road means a direct loss of income.

The market now follows e-commerce standards: speed, transparency, and autonomy. For professionals, this demands flawless organisation.

The reasons behind the rise of at-home services.

The constraints of mobile garages: complex logistics

An operation where the unexpected rules

Service calls span multiple towns, sometimes entire regions. A traffic jam on the ring road? A customer who says “I’ll be there in five minutes”? An emergency puncture that comes in at 10 a.m.? And the entire schedule has to be reworked.

In the field, the same constraints come up again and again:

- Long travel distances that are hard to optimise

- Cascading delays

- Last-minute cancellations

- High mental load for teams

☝️ Without optimisation, a technician often travels 120 km for just 6 to 8 jobs. Some companies lose up to 45 minutes a day purely to phone calls, rescheduling, and makeshift planning.

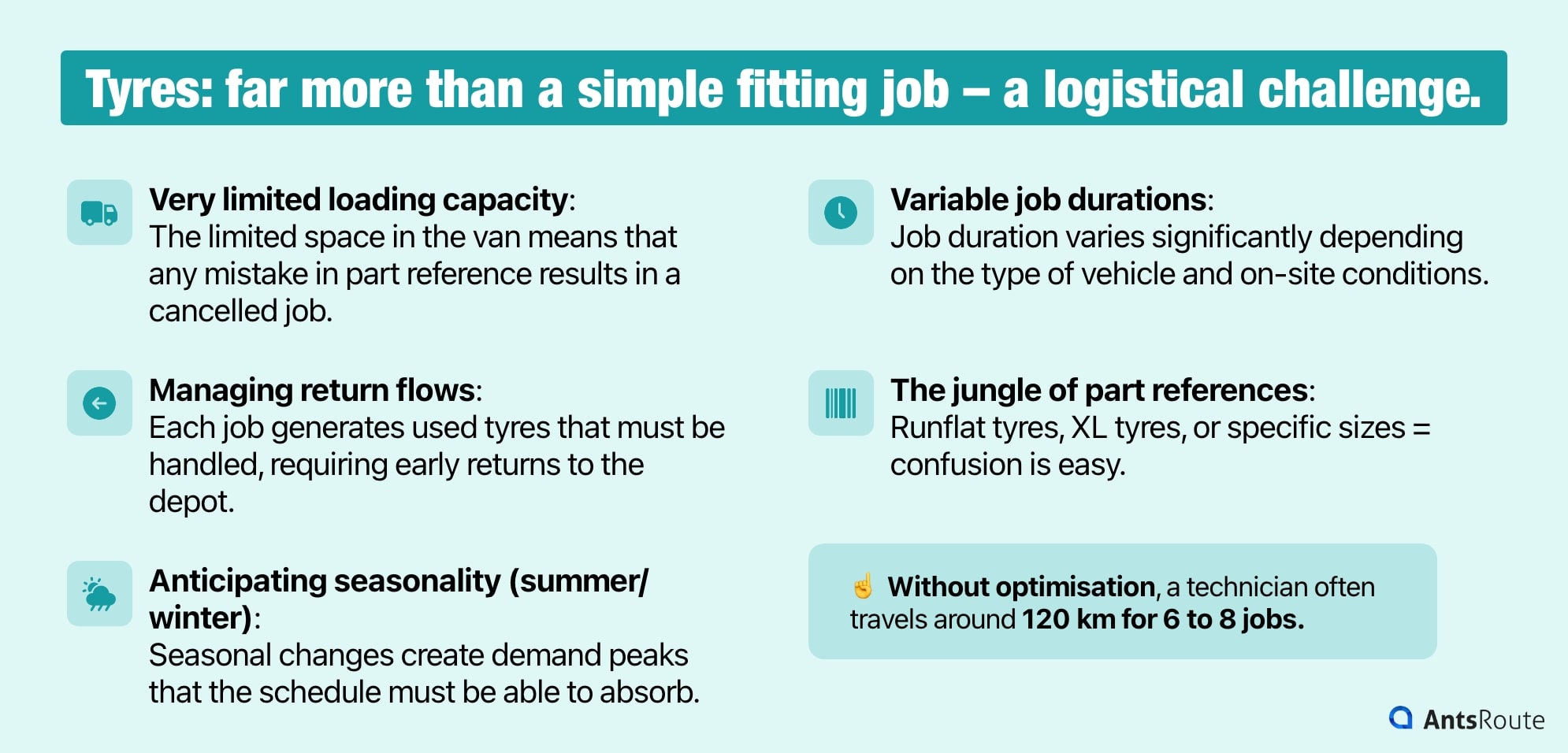

Tyres: far more than a simple fitting, but a logistical challenge

Changing tyres at home may seem straightforward at first glance. In reality, it is a complex operation where the equipment leaves no room for error.

- Severely limited load capacity: A van isn’t expandable. Technicians must juggle a restricted inventory and bulky equipment. The slightest reference error (size, load index) means a cancelled job and a round trip back to the depot.

- A jungle of specifications: Runflat, XL, or specific sizes (205/55 R16, 225/40 R18, etc.)—confusion comes easily.

- Anticipating seasonality (summer/winter): Winter tyres, summer tyres, all-season tyres, large-scale fleet changeovers… schedules must absorb demand without collapsing.

- Highly variable service times: A small city car may take 20 minutes, while an SUV with seized wheel nuts or a reinforced commercial vehicle can take twice as long, especially if the vehicle is poorly parked.

- Managing return flows: Often overlooked, but every tyre fitted creates a worn tyre that must be stored and recycled. This reverse flow requires regular returns to the depot, which must be planned into routes to avoid overloading the van.

The logistical challenges of at-home tyre fitting.

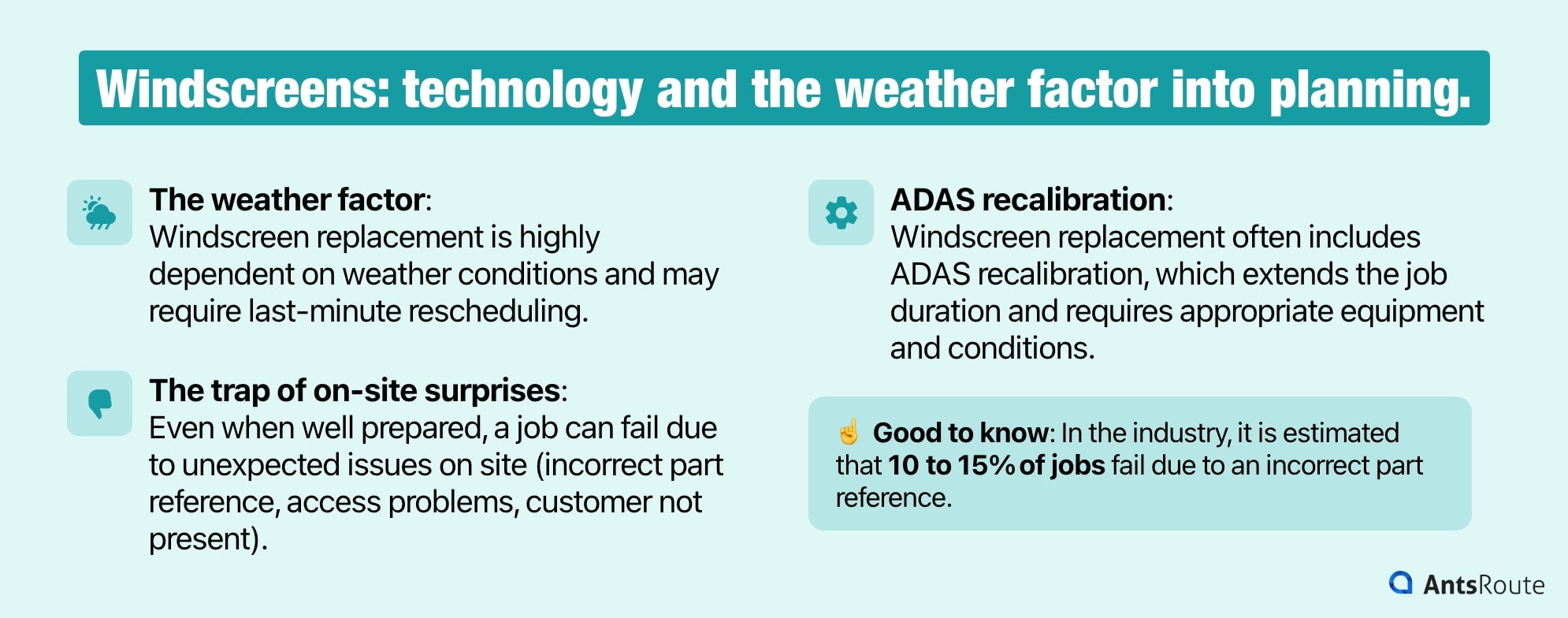

Automotive glass: when technology and weather disrupt scheduling

Replacing a windscreen cannot be improvised. It is a surgical operation subject to external constraints.

- The weather factor: Unlike tyres, automotive glass requires strict conditions. Rain, strong winds, or insufficient light? The job is compromised. Technicians sometimes have to improvise using tarps or mobile tents, or, worse, reschedule appointments at the last minute.

- ADAS recalibration: Gone are the days when replacing a windscreen was just a matter of fitting new glass. Today, it often involves recalibrating driver-assistance cameras and sensors. This step significantly extends service time and requires specialised equipment and a stable environment.

- The trap of on-site surprises: Even with thorough preparation, technicians may arrive to discover the wrong part reference (incorrect model or ADAS configuration), an inaccessible vehicle, impossible access (a car park with insufficient height clearance), or a no-show customer.

☝️ Good to know: Across the industry, it is estimated that 10–15% of service calls fail due to an incorrect part reference. With a tool like AntsRoute, which secures data accuracy from the moment the appointment is booked, this rate drops to under 3%.

The logistical challenges of at-home windscreen replacement.

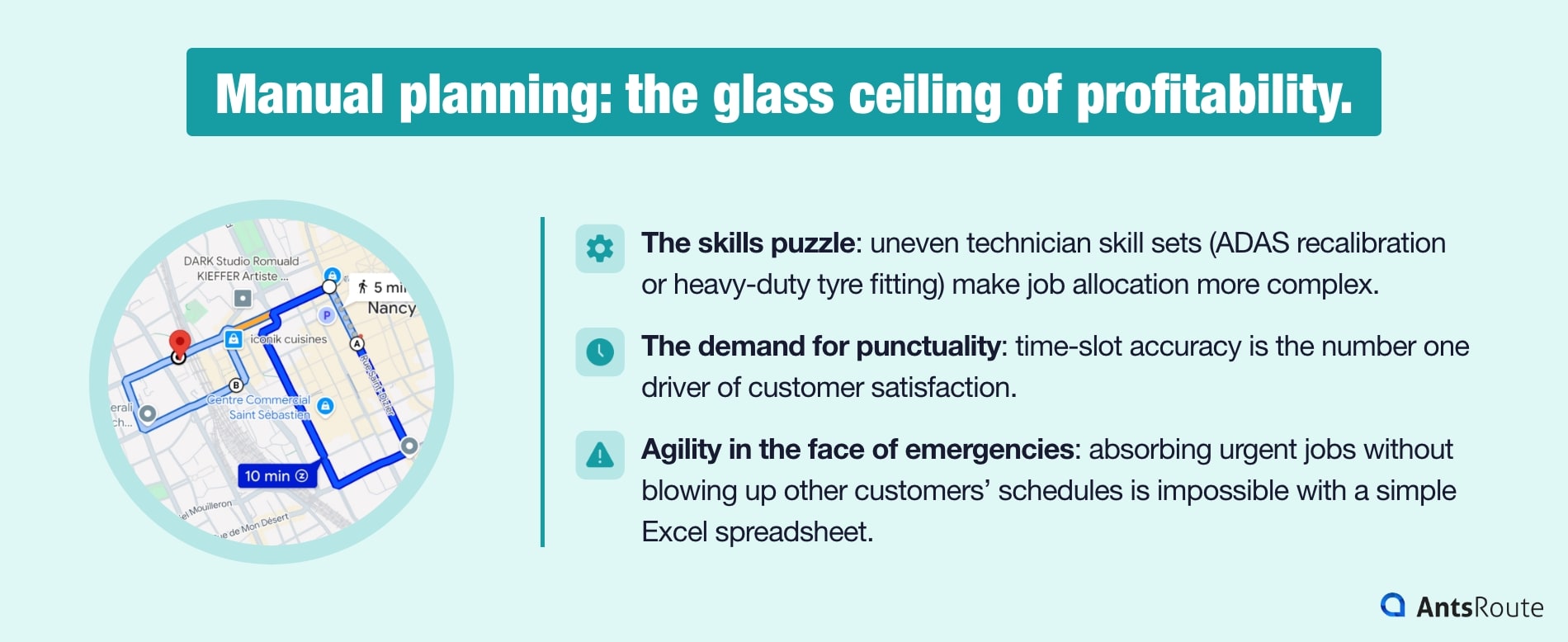

Manual scheduling: the glass ceiling of profitability

Combining tyre and automotive glass operations creates an organisational puzzle that human intuition alone can no longer solve.

- The skills headache: Not all technicians are trained in ADAS recalibration or heavy-duty tyre fitting. Assigning the right person to the right job becomes a daily headache.

- The punctuality requirement: Today, a customer left waiting for two hours without any update is guaranteed to leave a negative review. Time-slot accuracy is the number-one driver of satisfaction.

- Agility in the face of emergencies: “My crack got worse this morning,” “I had a puncture at lunchtime”… Absorbing these requests without blowing up the rest of the schedule is impossible with a simple Excel spreadsheet.

The conclusion is clear: without intelligent automation, planners and technicians burn out managing emergencies instead of driving growth. Improvisation is no longer a viable strategy. It’s time to change, and adopt AntsRoute.

The limits of manual planning for tyre and windscreen operations.

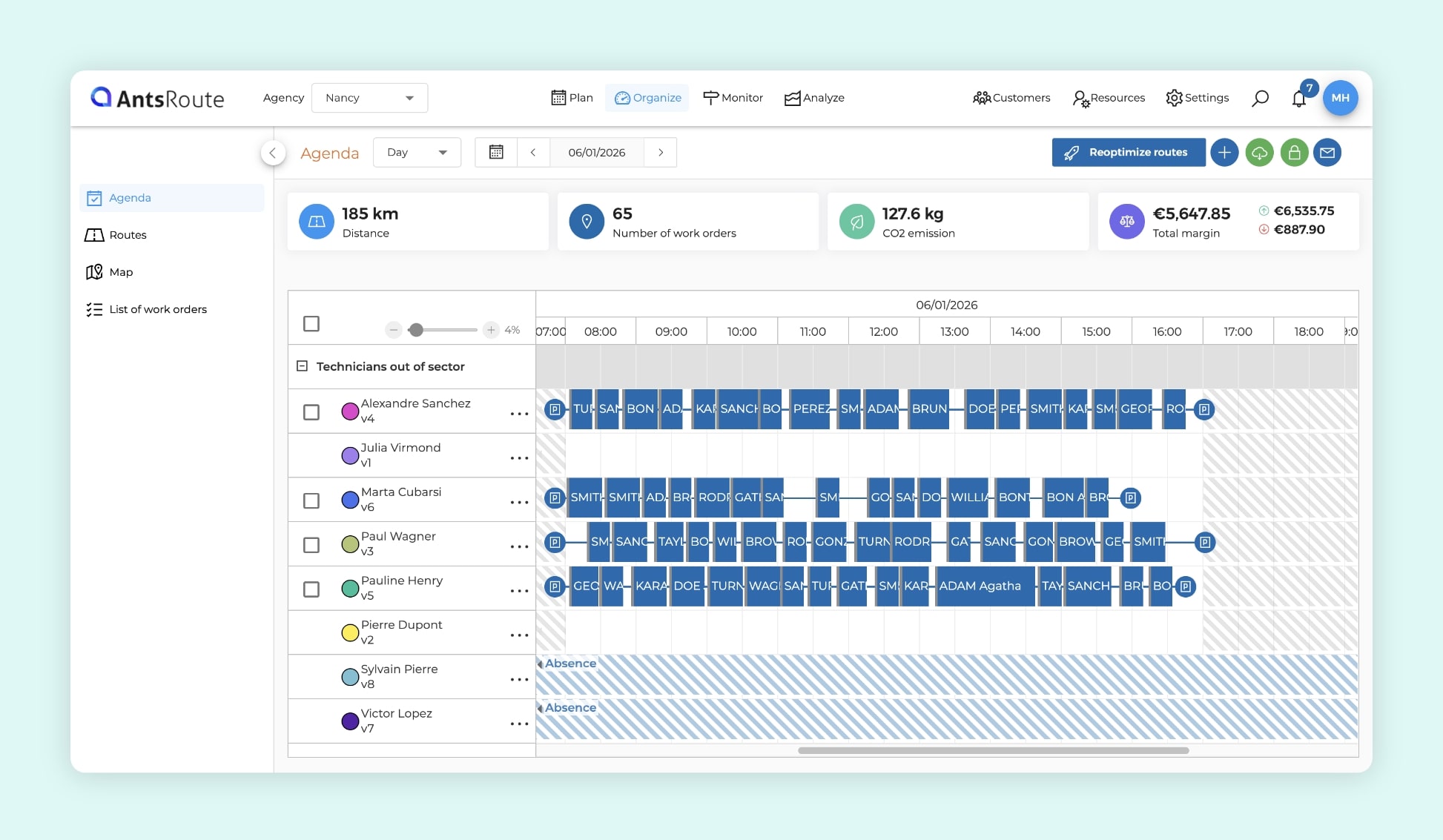

How AntsRoute optimises your routes and transforms your mobile operations

Intelligent scheduling

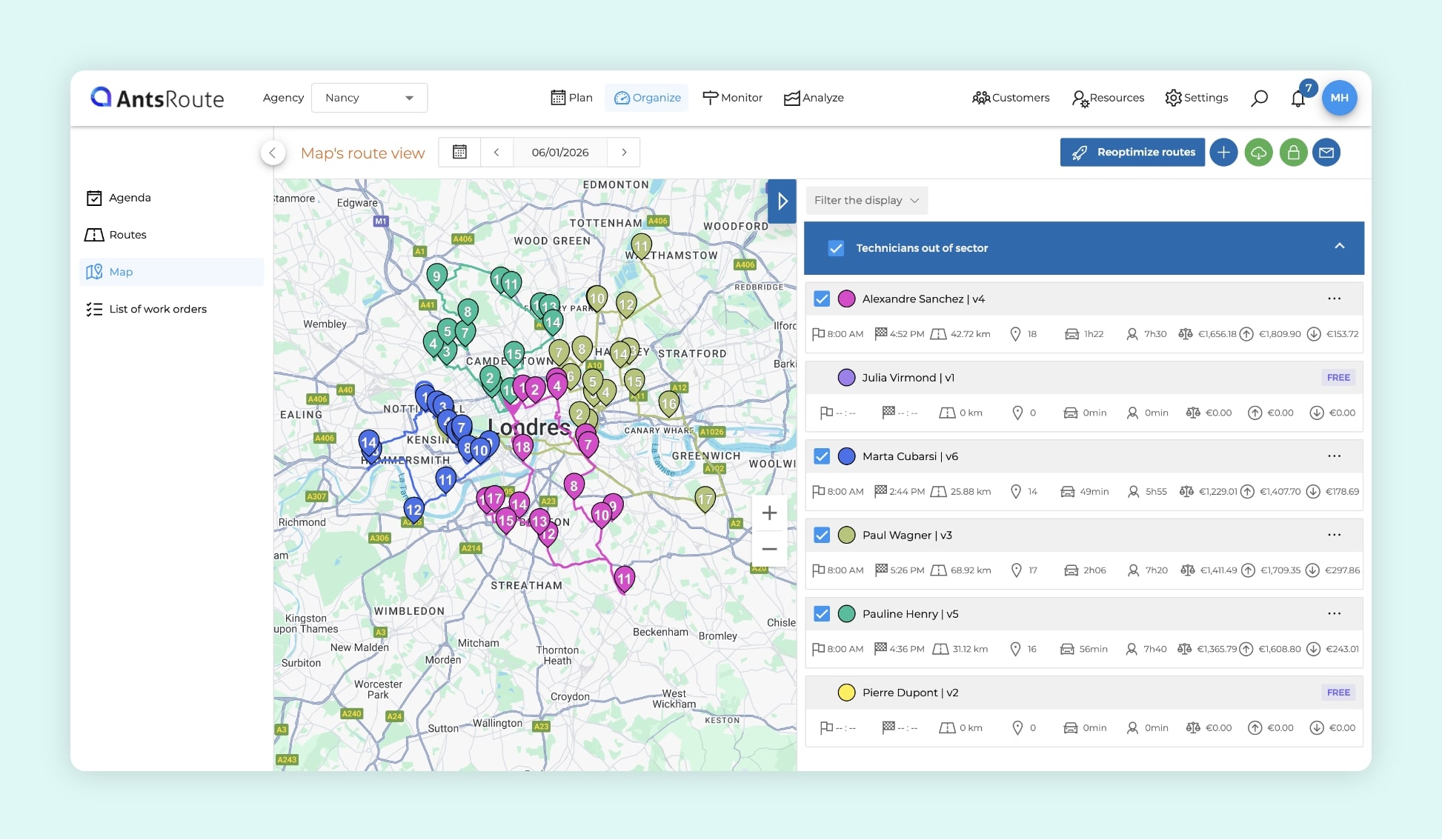

AntsRoute analyses in seconds what a human planner would take hours to organise: travel times, available time slots, technician skills, job durations, onboard inventory, and more.

- ✅ Automatically optimised time slots: When an appointment is booked, the software suggests the best possible slot, minimising mileage while respecting your service areas.

- ✅ Fair workload distribution: No more days starting with 8 jobs for one technician and 4 for another. The algorithm balances assignments across technicians based on their skills.

- ✅ 24/7 booking: Customers choose their own slot via an online booking page. The system automatically blocks impossible options, ensuring schedules remain realistic, coherent, and executable at all times.

☝️ A tyre and automotive glass company eliminated assignment errors in just one week. Result: +1 job per technician per day, without any additional hires.

A coherent, achievable schedule generated with AntsRoute.

Real-time optimisation

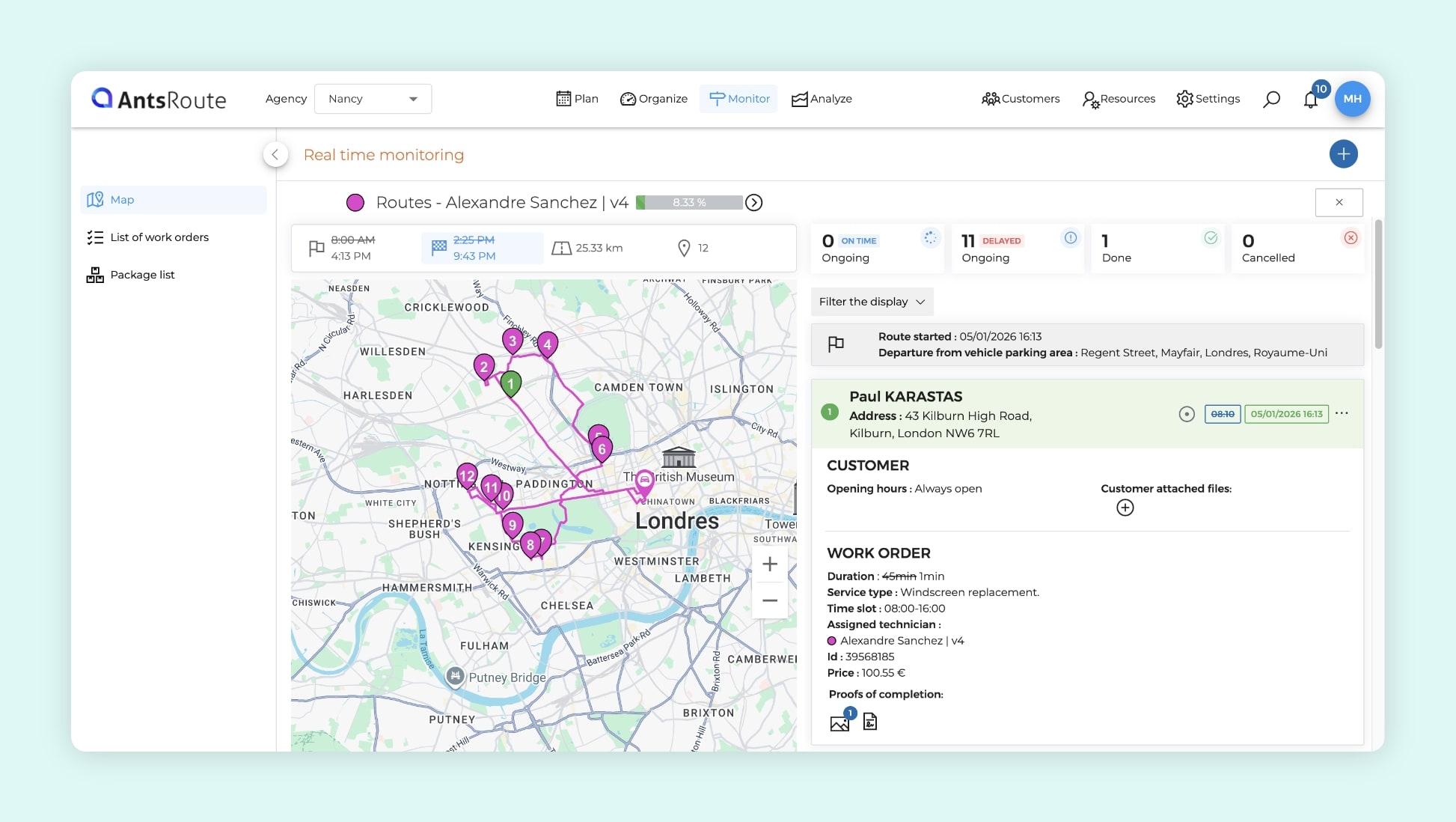

As you know, nothing ever goes exactly as planned: traffic jams, no-show customers, incorrect tyres, puncture emergencies, weather disruptions… the list goes on.

With AntsRoute, your routes are instantly reorganised:

- ✅ Surgical responsiveness: A customer cancels at 9 a.m.? The schedule automatically tightens. A glass emergency comes in at 11 a.m.? The tool finds the best available slot. A job finishes early? The next one is brought forward.

☝️ One automotive glass company reduced its mileage by 28% during a frost episode.

Fewer kilometres means gains across the board: fuel savings, reduced vehicle wear, lower team fatigue, and a smaller carbon footprint.

Route optimisation with AntsRoute.

Digital tracking and proof of service

In the automotive sector, traceability is your best protection. AntsRoute centralises everything in an intuitive mobile app for technicians.

- ✅ Visual proof: Technicians upload before/after photos (initial damage, replaced windscreen, newly fitted tyres).

- ✅ Paperless reports: Customer signature, fitted part references, completed steps, and time spent are recorded in a single click.

- ✅ No re-entry: Thanks to automatic synchronisation (via API or Zapier), data flows directly into your CRM or ERP system.

☝️ Disputes were divided by five thanks to timestamped photos.

Real-time route tracking with AntsRoute.

Automated communication: the end of no-shows

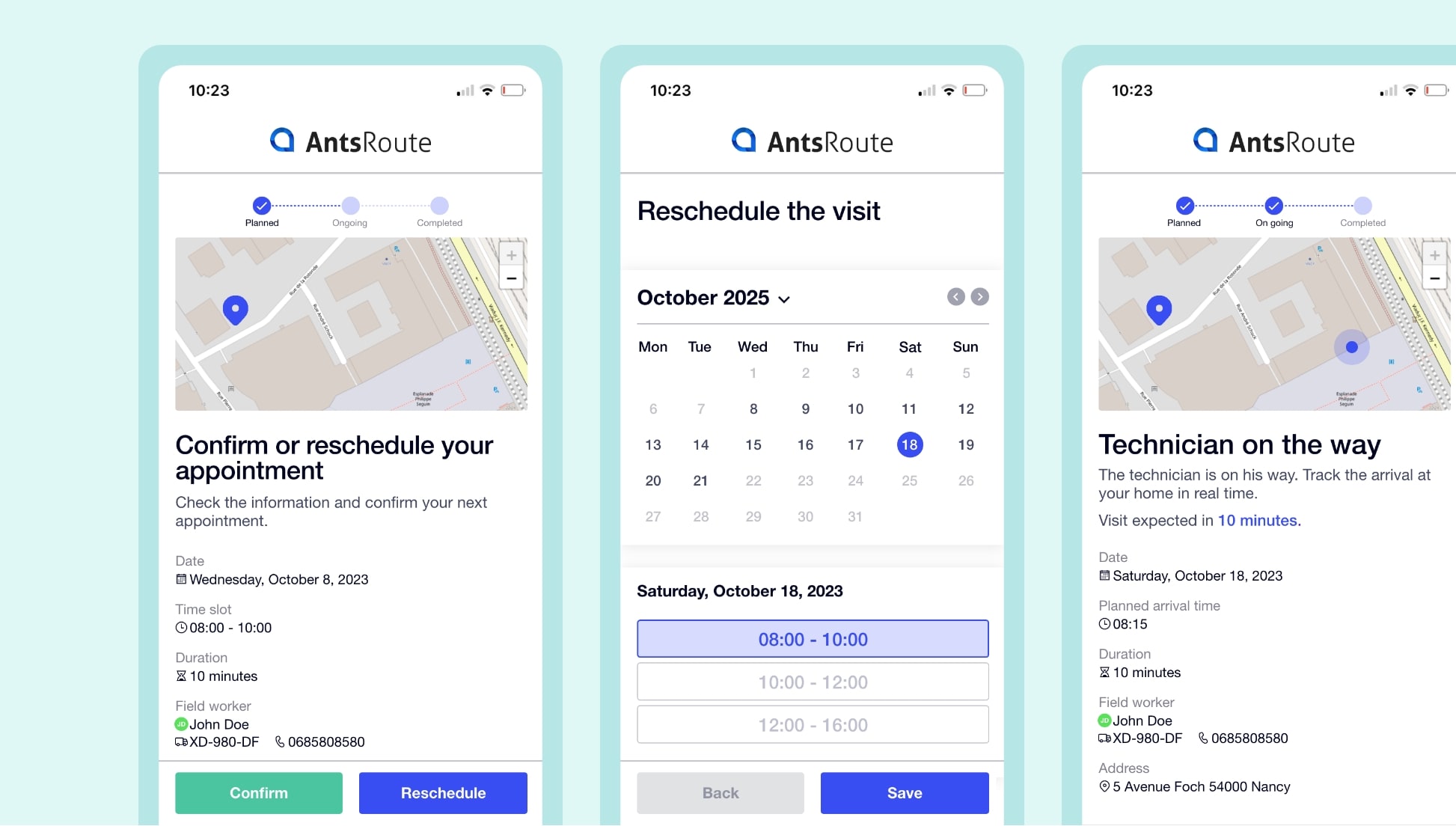

A no-show customer means a lost job, and a technician who travelled for nothing. AntsRoute helps secure appointments:

- ✅ Automatic reminders: Sent by SMS or email, they reduce forgotten appointments by 30–50%.

- ✅ Tracking link: Customers receive a “Your technician is on the way” notification with a live GPS tracking link.

- ✅ Fewer delays, higher customer satisfaction: A well-controlled day is immediately reflected in customer reviews and word of mouth.

Rescheduling and tracking links sent via AntsRoute.

Advanced features that change everything

AntsRoute doesn’t just draw lines on a map, it adapts to the realities of field operations:

- Flow management (Pick-up & Delivery): Automatically schedule depot visits to unload used tyres or replenish stock during the day.

- Integrations & APIs: Easy connection with industry-specific CRMs, ERPs, online booking tools, and Zapier.

- Data-driven management (KPIs): Track your key metrics (on-time performance, kilometres travelled per technician, average job duration, number of jobs per day).

☝️ Some users have reduced travel time from 22% to 14%, gaining up to one extra hour of productivity per technician per day.

The showdown: manual scheduling vs automated optimisation

| Criteria | Manual planning (Excel/Paper) | Management with AntsRoute |

| Number of operations | Limited by random routing | +1 to 2 operations per day/technician |

| Daily mileage | High and uncontrolled | -20% to -30% fewer kilometres travelled |

| Punctuality | Random/inconsistent (often more than 30 minutes late) | High precision (95% on-time compliance) |

| Cancellations/no-shows | High | Significantly reduced thanks to automatic notifications |

| Team stress | Very high (constant improvisation) | Low and controlled (clear, realistic scheduling) |

| Returns to the depot | Rarely integrated into the route | Automatically integrated when needed |

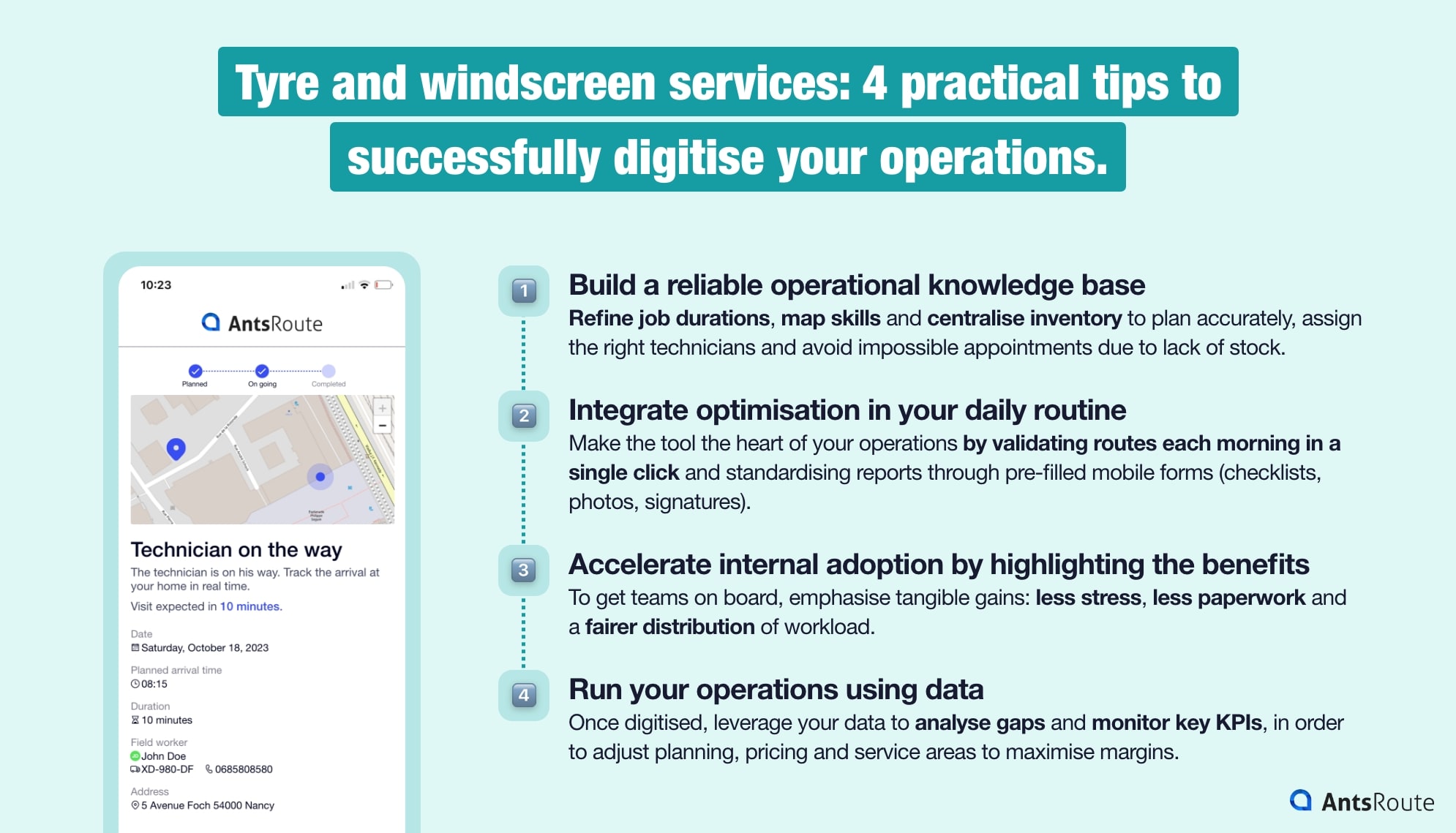

4 practical tips to successfully digitise your operations

1. Build a reliable operational knowledge base

For an algorithm to be effective, it must reflect the reality of your day-to-day operations. Don’t rely on vague estimates.

- Refine job durations: Differentiate between the time required for a simple chip repair and a full windscreen replacement with ADAS recalibration.

- Map skills accurately: Clearly list which team members are qualified for each type of work.

- Centralise inventory: Link stock availability to appointment booking so you never schedule a tyre fitting for products you don’t have in stock.

2. Embed optimisation into your daily routine

The tool should not be an additional burden, but the core of your organisation:

- The morning reflex: Validate routes in one click so each technician receives their digital route sheet on their smartphone before even starting the vehicle.

- Standardise your reports: Leave no room for interpretation. Use pre-filled mobile forms (checklists, photos, signatures).

3. Accelerate internal adoption by highlighting field benefits

Change can be unsettling. To bring teams on board, show them what they gain:

- Less stress: Show them the tool is there to help them avoid traffic jams and constant calls from the office asking “where are you at?”.

- The end of paperwork: Emphasise that digital reports replace paper logbooks that are often lost or poorly filled in at the end of the day.

- Fair workload distribution: Demonstrate that the software ensures a balanced allocation of work, preventing the same technicians from consistently being assigned the densest areas.

4. Run your operations with data

Once digitised, your mobile garage generates a wealth of information. Put it to work:

- Analyse variances: If a team consistently takes 15 minutes longer than planned on glass jobs, adjust your scheduling parameters to improve realism.

- Track your strategic KPIs: What is your first-time fix rate? What is the average cost per kilometre per job? These metrics will help you fine-tune pricing or service areas to maximise margins.

Tyre and windscreen operations: 4 practical tips to successfully digitise your business.

At-home tyre and automotive glass replacement is no longer just an alternative to the traditional garage. It has become the standard for a demanding customer base that is primarily buying peace of mind and time. By adopting AntsRoute, you’re not just reducing mileage: you’re giving your technicians breathing room, securing your margins, and delivering a customer experience worthy of e-commerce leaders.

Try AntsRoute free for 7 days and take back control of your mobile operations.

➡️ View our pricing

➡️ Request a free demo or contact our team to learn more about our solutions for professionals in at-home tyre and automotive glass replacement.

WRITTEN BY

Florine Martin

Florine has been a freelance web copywriter since 2021, writing for a variety of clients in a range of sectors. Since the beginning of 2024, she has been writing articles about logistics for our company, AntsRoute.

Free 7-day trial | No credit card required

Contenu

- A rapidly changing market: when the garage comes to the customer

- Tyres and automotive glass: two key activities under pressure

- Highly technical operations under intense operational strain

- The rise of at-home service: flexibility takes centre stage

- The constraints of mobile garages: complex logistics

- An operation where the unexpected rules

- Tyres: far more than a simple fitting, but a logistical challenge

- Automotive glass: when technology and weather disrupt scheduling

- Manual scheduling: the glass ceiling of profitability

- How AntsRoute optimises your routes and transforms your mobile operations

- Intelligent scheduling

- Real-time optimisation

- Digital tracking and proof of service

- Automated communication: the end of no-shows

- Advanced features that change everything

- The showdown: manual scheduling vs automated optimisation

- 4 practical tips to successfully digitise your operations

- 1. Build a reliable operational knowledge base

- 2. Embed optimisation into your daily routine

- 3. Accelerate internal adoption by highlighting field benefits

- 4. Run your operations with data