Towards Green Logistics: a Comprehensive Guide about the Issues and Innovations Involved

Today, environmental concerns are at the heart of decision-making for many companies, and logistics is no exception to this trend. Green logistics, also known as sustainable logistics, has become a major challenge for carriers, logistics providers and distributors. But how do you navigate through all these green standards and solutions?

This article is intended as a practical guide to help you navigate this maze of constraints and issues:

- Discover the 5 main environmental challenges that logistics is facing, as well as the objectives set by the legislation.

- Explore 6 concrete innovations that can make your operations greener while remaining efficient.

The Green Logistics, thanks to logistics innovations, enables carriers to reduce their environmental impact. By adopting this approach, transport companies gain in efficiency and meet customers’ expectations in terms of ecological responsibility.

What is Green Logistics?

If you work in the transport, logistics or distribution sector, you’ve probably heard of green logistics. This concept includes all the actions aimed at making your activities more environmentally friendly, while maintaining their performance.

Green logistics includes measures such as reducing CO₂ emissions, optimising the use of resources and energy, developing a circular economy, and sustainable waste management. But that’s not all: it also seeks to protect biodiversity by reducing the impact of logistics infrastructure and transport on natural ecosystems.

In Europe, the climate emergency is forcing logistics players to review their practices, with the aim of achieving carbon neutrality by 2050. Green logistics is no longer an option, it’s a necessity. But it also represents an opportunity to innovate and transform your business, while reducing your carbon footprint.

The 5 main environmental challenges of green logistics

For a better understanding of the issues facing the logistics industry, let’s take a look at five major environmental challenges and the legislative measures associated with them.

The 5 environmental challenges of green logistics.

1. Reduction in CO₂ emissions

Freight transport, warehouse management and distribution account for a significant proportion of greenhouse gas (GHG) emissions. The transport sector in Europe is responsible for 25% of CO₂ emissions, with around 77% of EU emissions coming from road freight transport in 2020.

The aim is ambitious: to reduce GHG emissions by 55% by 2030, compared with 1990 levels, so that Europe becomes the first climate-neutral continent. This target has been strengthened from the previous target of a 40% reduction to align with the wider objective of becoming carbon neutral by 2050. In France, for example, transport companies have already been forced since 2015 to declare to their customers the quantities of greenhouse gases emitted for the delivery they carry out, in accordance with the Code des transports. But from now on, all companies with more than 500 employees must also declare these indirect emissions in their carbon accounting (see our article on decarbonising scope 3).

2. Air pollution and noise pollution

In addition to CO₂ emissions, transport is responsible for 40% of nitrogen oxide (NOx) emissions, 11-15% of fine particles (PM 2.5) and 10-15% of volatile organic compounds (NMVOCs). In urban areas, logistics alone generates 30-50% of atmospheric pollutants. These emissions contribute to air pollution, which causes more than 400,000 deaths in Europe every year, according to the European Environment Agency (EEA). Noise pollution, from heavy goods vehicles and logistics infrastructures, also creates a major nuisance, especially in urban areas. These two issues have a major impact on people’s quality of life, and call for concrete measures to reduce them. (see our article on sustainable urban logistics)

The objectives for 2030 are clear: to reduce emissions of fine particles, volatile organic compounds (VOCs) and nitrogen oxides by more than 50%. This will involve extending Low Emission Zones (LEZs) in major conurbations and moving towards vehicles that comply with the Euro 6 Regulation on CO₂ emission standards for HDVs, and with Euro 7 scheduled for 2027.

3. Energy consumption of warehouses

Logistics is an extremely energy-intensive sector. And it’s not just transport vehicles that are to blame.

There are more than 1,500 warehouses/logistics hubs in the UK, covering almost 430 million sq.ft. The operation of warehouses requires continuous energy consumption for tasks such as heating, cooling goods, lighting and powering automation systems. Refrigerated warehouses, for example, consume 3 to 5 times more energy than a normal warehouse.

To meet this challenge in France, the Éco Énergie Tertiaire (EET) decree requires a 40% reduction in the final energy consumption of warehouses by 2030, compared with a baseline year between 2010 and 2019.

4. Impact on ecosystems

The building of logistics infrastructures contributes to the artificialisation of soils, which threatens biodiversity by fragmenting the natural habitats of flora and fauna. Logistics warehouses account for more than 1% of these artificialised areas in Europe. In the UK, 6,000 hectares of natural and agricultural land are lost every year. In France, the figure reaches 22,000 hectares.

In the UK, the National Planning Policy Framework (NPPF) emphasises sustainable development and encourages the use of industrial wastelands (previously developed lands) before greenfield lands, in order to limit the expansion of urbanisation into natural and agricultural areas.

In Europe, the Climate and Resilience law requires the consumption of natural and agricultural areas to be reduced by 50% by 2031 (compared with 2021), with the ultimate aim of achieving Zero Net Artificialisation (ZNA) by 2050.

5. Optimisation of resources: traceability and re-use

The waste of resources is also a major challenge for the supply chain as a whole. In the food industry alone, 88 million tonnes of food are thrown away every year in Europe, including 9.5 million tonnes in the UK alone. Some of these wastes are due to excessive production, insufficient traceability or failure to respect use-by dates. And the same applies to other sectors. Not to mention the large amount of single-use packaging and the harmful materials it contains.

The UK Resources and Waste Strategy for a circular economy, enacted in 2018, seeks to move away from plastic and disposable packaging and promote repair and re-use. In particular, it introduced a tax on plastic packaging containing less than 30% recycled plastic to reduce the consumption of single-use plastic.

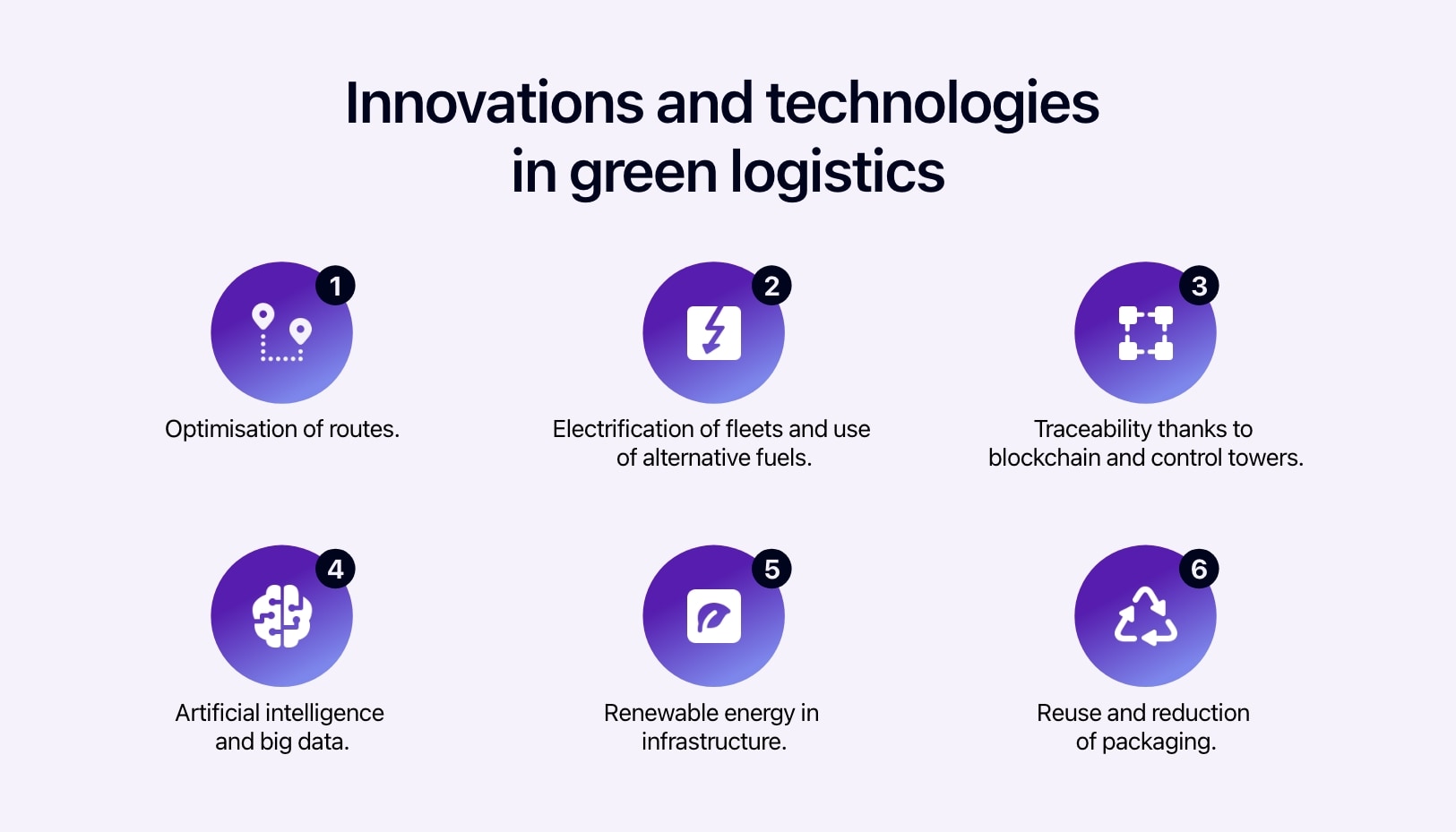

6 innovations and technologies in green logistics

To meet these environmental challenges, technologies and innovations have emerged to enable companies to combine performance and sustainability.

Here’s a look at some of the most promising solutions.

Innovations and technologies in green logistics.

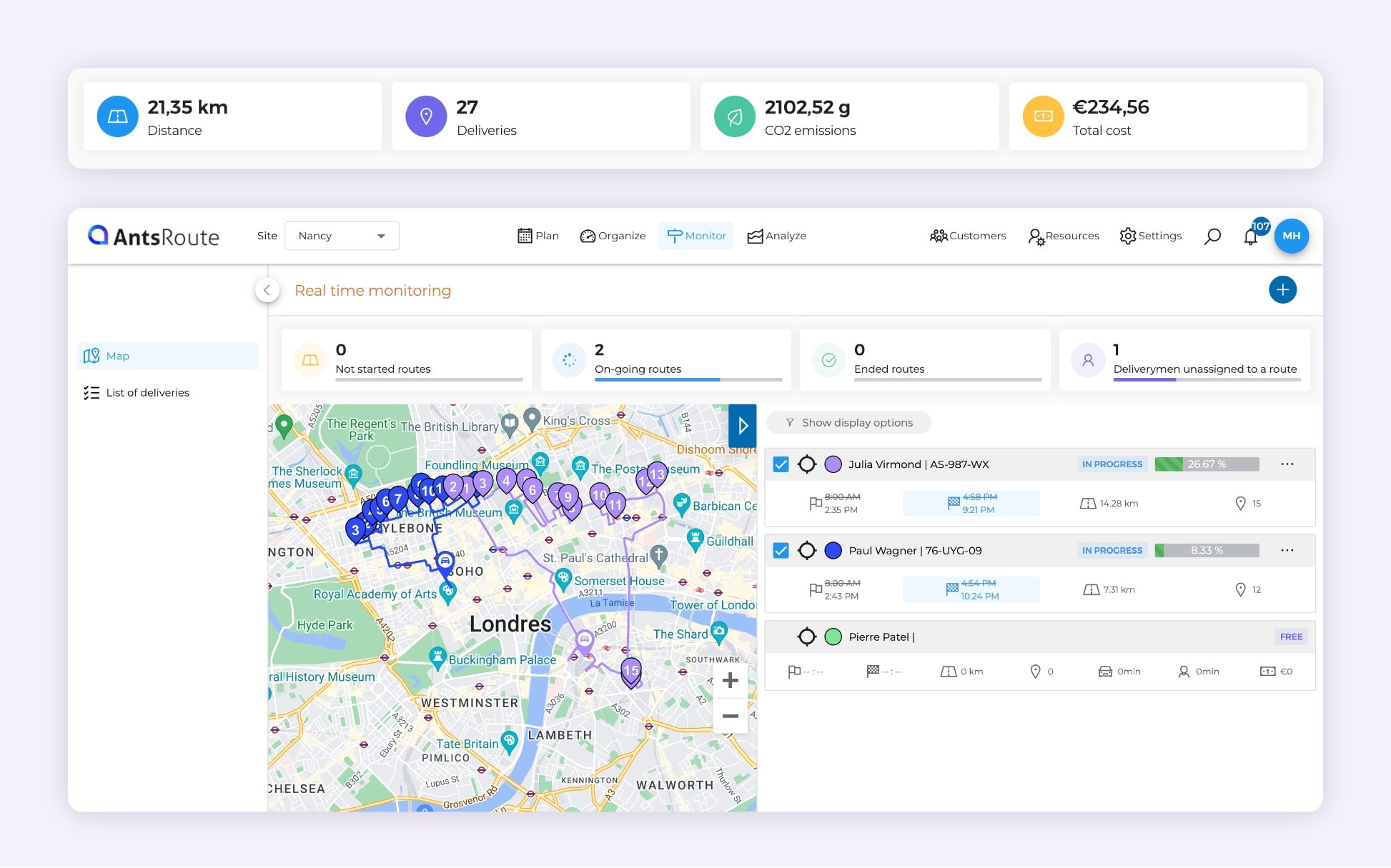

1. Optimisation of routes

Route optimisation is one of the most effective ways of reducing CO₂ emissions. Tools like AntsRoute can create the best routes that take into account traffic, CO₂ emissions, delivery constraints and vehicle capacity. Thanks to these advanced algorithms, companies can reduce empty returns and limit the number of kilometres driven.

The route optimisation not only improves ecological efficiency, it also contributes to greater customer satisfaction, by offering more precise delivery times and better management of time slots.

The optimisation of delivery routes on AntsRoute.

2. Electrification of fleets and use of alternative fuels

The adoption of low-emission vehicles is another key innovation in the move towards greener logistics. Many hauliers are now turning to electric solutions or alternative fuels such as BioNGV. A global company like Leroy Merlin is aiming to reduce its CO₂ emissions by 72% by 2025 through the use of alternative energies from the warehouse.

Transport companies mainly use electric vehicles and cycle logistics for last-mile deliveries in urban areas. Tests are under way with companies such as CEVA Logistics to solve the problem of long-distance charging and extend their use.

In addition, new technologies are emerging, such as renewable hydrogen-powered trucks, although their acquisition costs remain high at this stage, as is the case for electric vehicles.

Multimodal solutions such as Everysens’ TVMS software and the Ecofluv zero-emission barge are being developed to make these routes more accessible.

3. Traceability thanks to blockchain and control towers

Blockchain seemed promising at the start of the 2020s, but the projects that have been launched are struggling to get off the ground. Shipping giant Maersk put an end to its Tradelens digital platform in 2023, considering it to be ‘commercially unviable’. By recording every stage in the journey of goods in a transparent and forgery-proof way, it improves product traceability, reduces the risk of error, and guarantees compliance with environmental and social standards. Stay tuned.

However, new solutions are emerging, such as order control towers (OCT), which offer complete end-to-end order tracking. For example, the WIMO platform provides continuous monitoring of logistics flows, enabling orders to be rerouted if necessary. This avoids unnecessary breaks or losses, while guaranteeing optimum responsiveness to improve operational efficiency.

4. Artificial intelligence and big data

Artificial intelligence (AI) and big data are bringing revolutionary solutions to green logistics. These technologies can analyse massive volumes of data to identify inefficient patterns or opportunities for optimisation. For example, AI can predict fluctuations in demand, enabling transport volumes to be better adapted and empty returns to be avoided.

Predictive algorithms also help to anticipate breakdowns and reduce vehicle downtime, thereby improving fleet efficiency. They can also simulate transport patterns, with Digital Twin solutions such as those offered by DC Brain or Solystic. Coupled with route optimisation, these technologies enhance the sustainability of operations while improving companies’ economic performance.

5. Renewable energy in infrastructure

This area is also expanding rapidly. Many warehouses are equipping themselves with solar or photovoltaic panels, reducing their dependence on fossil fuels. The installation of charging points for electric vehicles, directly on logistics sites, makes the electrification of internal and external fleets even more efficient.

Some manufacturers are going even further by adopting passive warehouse structures that minimise energy consumption through high-quality thermal insulation and optimised air flow. These innovations are helping to significantly reduce the carbon footprint of logistics infrastructures. Virtuo Industrial Property is a prime example of this with its Net ZERO carbon projects. Its latest V. Park site in Nantes, France, has a very limited carbon footprint, with an interior and exterior layout that promotes well-being and biodiversity.

A goods warehouse powered by solar panels.

6. Reuse and reduction of packaging

The management of packaging should not be forgotten either, given its considerable environmental impact: 39% of the overall logistics impact of parcel deliveries according to a study carried out by La Poste in 2023. The reduction or adaptation of packaging, and the reuse of cardboard boxes, containers and logistics equipment by companies such as Carton Vert, Paki Logistics, or Actemium Tour Logistics help to limit the production of waste and preserve natural resources.

Today, many companies are taking steps to reduce the use of non-recyclable packaging, by favouring sustainable materials or reusable solutions. But there is also a whole new economy to be built, with massive development of the circular economy. And logistics is the real spearhead.

Conclusion

Technological innovations in green logistics offer concrete solutions for reducing the environmental impact of this sector. From route optimisation, which reduces the number of kilometres travelled and CO₂ emissions, to the adoption of electric vehicles, not to mention the reduction in packaging, logistics stakeholders now have effective tools at their disposal to meet the climate challenges.

By embracing these innovations, you can not only improve your operational efficiency, but also meet your customers’ growing expectations in terms of ecological responsibility. AntsRoute, through its route optimisation solutions, is fully committed to this dynamic transition towards greener, more sustainable logistics.

WRITTEN BY

Maryline Lakh

Maryline worked for a major logistics company for 15 years. Since 2022, she has been an expert in communication and freelance writer for positive-impact logistics companies. She is passionate about new sustainable logistics solutions and writes for several clients, including AntsRoute.

Free 7-day trial | No credit card required

Contenu

- What is Green Logistics?

- The 5 main environmental challenges of green logistics

- 1. Reduction in CO₂ emissions

- 2. Air pollution and noise pollution

- 3. Energy consumption of warehouses

- 4. Impact on ecosystems

- 5. Optimisation of resources: traceability and re-use

- 6 innovations and technologies in green logistics

- 1. Optimisation of routes

- 2. Electrification of fleets and use of alternative fuels

- 3. Traceability thanks to blockchain and control towers

- 4. Artificial intelligence and big data

- 5. Renewable energy in infrastructure

- 6. Reuse and reduction of packaging

- Conclusion