Tips to Reduce your Logistics Costs

You know that logistics costs account for a significant percentage of a company’s expenses. But did you know that you can optimise them to increase your profits? But how can you reduce these costs without sacrificing service or customer satisfaction? By accurately identifying the various cost categories and implementing effective strategies.

In this article, we share our tips to reduce your logistics costs and boosting your profitability. Find out how now!

Table of contents

Reducing logistics costs helps to boost the company’s profitability. Tailor-made transport solutions and better storage methods limit these expenses. This is the key to responding to future logistics challenges.

What is a Logistics Cost?

In short, logistics costs include all the costs incurred by a company in managing its goods: procurement, storage, labour, packaging, and transport. Whether incoming, stored or outgoing, these goods generate significant costs. According to the analysis ‘The promise and challenge of multi-client fulfilment for e-commerce’ by Mckinsey, these costs represent between 12 and 20% of revenues, although this percentage can vary depending on the industry.

In the United-Kingdom, the logistics sector contributes £139 billion Gross Value Added (GVA), highlighting its strategic importance to the economy.

The different types of logistics costs.

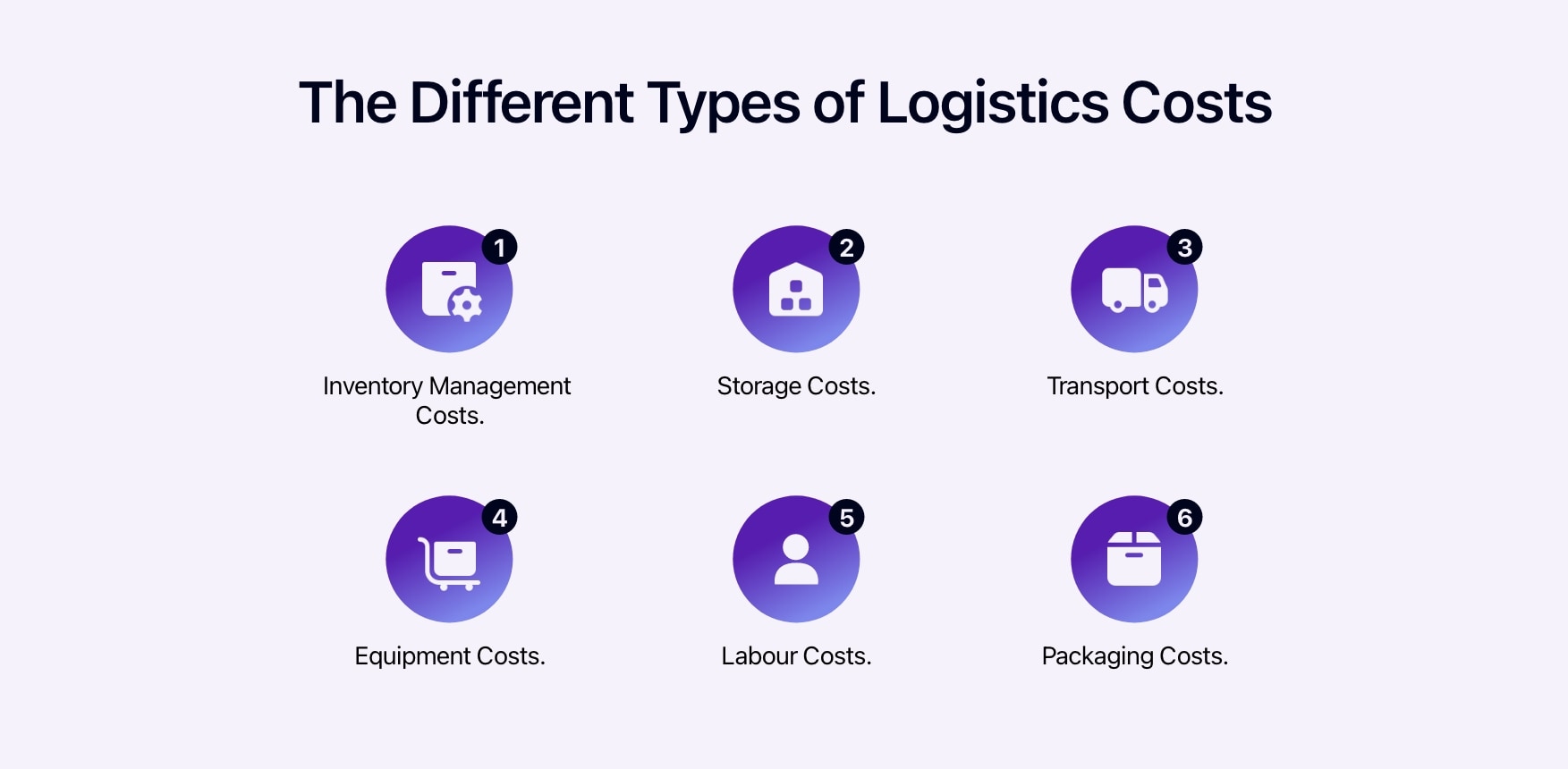

The Different Types of Logistics Costs

These costs can be grouped into six main categories:

Inventory Management Costs

These expenses include several key elements:

- Ordering Costs: related to stock acquisition and logistics costs.

- Holding Costs: include stock maintenance and shortage management. These costs vary depending on whether your company manages its inventory in-house or uses external suppliers.

- Shortage Costs: linked to the lack of merchandise, which can lead to loss of business and margin on sales.

Poor management of these costs can lead to a number of problems:

- Loss of customers

- Wasted stock

- Shipping delays

- Inaccurate forecasts

- Lower stock turnover rates

- Volatility of overheads

Storage Costs

Another factor that can lead to higher logistics costs is storage, or warehousing. Whether you produce your own goods or buy them from third parties, you need space to store them. The larger your inventory, the more storage space you need, which drives up costs.

Renting or buying a warehouse is only part of the equation. You also need to consider:

- Insurance to protect your assets

- Maintenance of your premises

- Security to prevent loss and damage

Investment is also needed in software, handling equipment, shelving and maintenance.

The warehousing involves high logistics costs.

Transport Costs

Whether you use the services of logistics experts or have your own in-house team, transport and distribution are difficult issues for any business.

Every movement, from stock in the factory to the customer’s door, represents an expense. What exactly is involved? Transporting your raw materials, moving your products from the factory to the warehouse, and finally delivering the goods to your customers. This logistics ‘dance’ can quickly become a financial headache if it’s not carefully orchestrated.

And we’re not going to lie, every step of the way has its cost. From the transport contract to a full tank of petrol, not forgetting the many detours involved in a last-mile delivery.

Poor stock management can compromise your profitability.

Equipment Costs

When it comes to efficient logistics management, you probably have the right tools for the job. Whether it’s physical equipment, such as forklift trucks or barcode scanners, or intangible, such as stock management and warehouse management software, they all play a key role in optimising your operations.

Labour Costs

Think about the human aspect to reduce your logistics costs! Behind every successful shipment is a dedicated team, whether it’s managing operations, ensuring quality customer service or carrying out logistics tasks.

Optimising these costs is not just about wages. It also includes the recruitment process, the onboarding of new talent, and investment in training. By taking these aspects into account, you can better assess and control your logistics costs.

Packaging Costs

The order picking is a key component that requires judicious investment. Every detail counts! From sturdy cardboard boxes to vacuum packaging, every choice is essential to guarantee product safety and optimum delivery.

5 Ways to Reduce Logistics Costs

Smart management of logistics costs will enable you to reduce your expenditure more efficiently. To achieve this, it’s essential to identify the right levers for making savings without compromising the quality of your deliveries. Here are some tips on how to reduce your costs!

The 5 ways to reduce logistics costs.

1. Optimising Last-Mile Delivery

Imagine yourself at the last and most costly delivery stage of your logistics process. And guess what? It’s also the one that has the biggest impact on your customers. Yet the planning of these deliveries is often in the hands of a few people, which can result in costly mistakes. You know what that means: delays or missed deliveries that can seriously damage the customer experience.

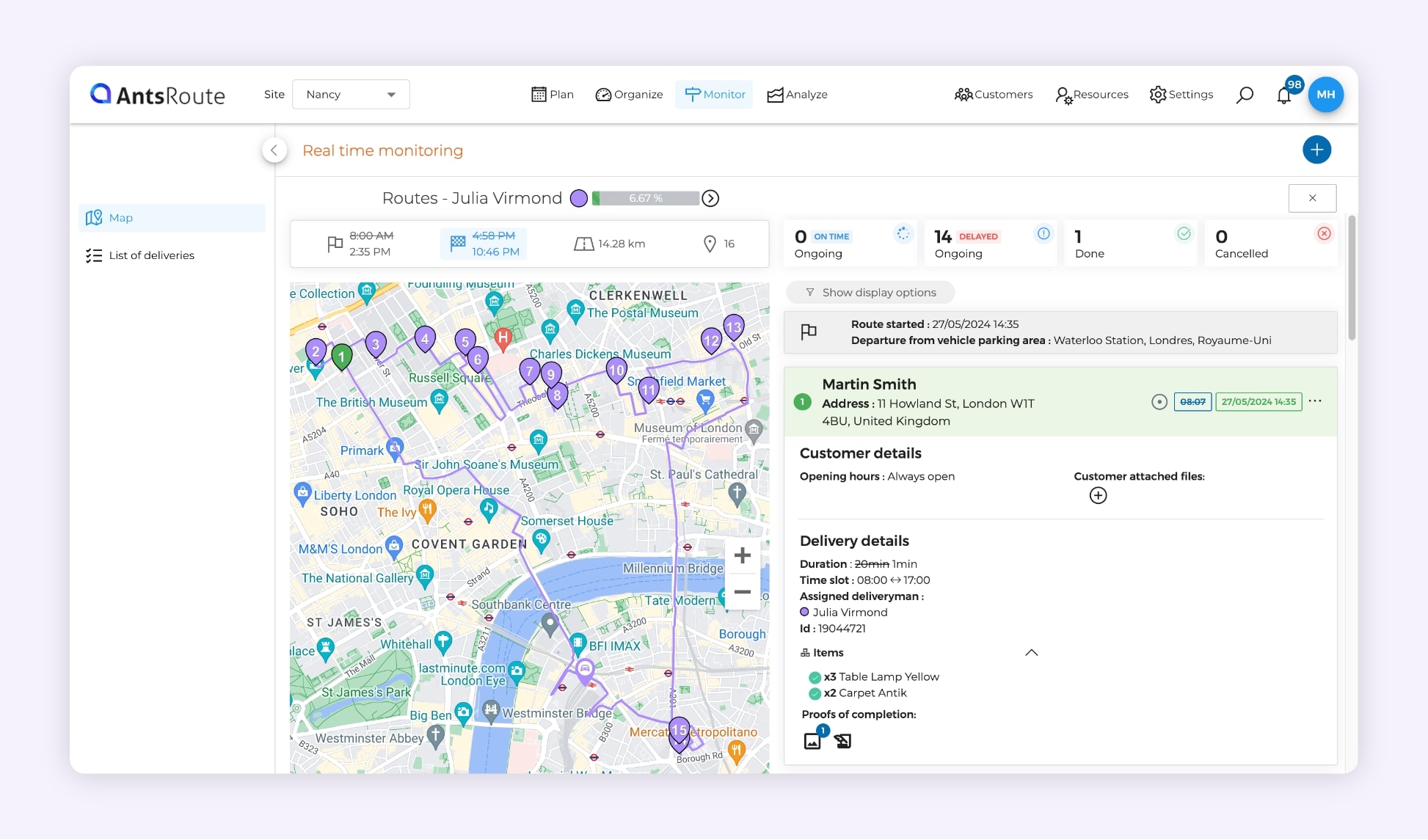

That’s where route planning and optimisation software like AntsRoute can help! Our solution enables you to create more efficient routes for your delivery staff, thereby reducing your road transport costs. By taking into account traffic, capacity of vehicles, skills of field workers and many other factors, AntsRoute optimises your delivery drivers’ workloads and helps you control your costs. In short, our services meet all the defined constraints.

Our reporting and analysis tools enable you to monitor the costs of routes, cancellation rates and the average quantity of goods transported per mile.

The optimisation of routes with AntsRoute helps to reduce logistics costs.

2. A Good Transport Service Provider

Choosing your transport service providers is crucial to keeping control of your logistics and transport costs.

It’s much more than just a matter of pricing. Here are a few key points to keep in mind:

- Reputation and experience: take into account the company’s reputation and feedback.

- Quality of service: make sure you choose one that is excellent at meeting your specific needs.

- Transparency and communication: a good carrier will give you transparent and accurate information about all the details of your delivery, so that you can better anticipate any unforeseen events.

To reduce your transport costs, understand how prices are determined and explore different options to get the best rates while maintaining service quality.

Organising regular calls for tenders enables you to compare offers and find the right balance between cost and quality. Whether or not you outsource your deliveries, the aim is to combine operational efficiency and cost control to offer the best service to your customers.

3. More Efficient Stock Management

The smaller your inventory, the less space you’ll need to store it, which means less expenditure on warehousing. But beware, reducing inventory can sometimes compromise your ability to respond quickly to customer requests and damage your reputation. Smart merchandise management is therefore the key to finding the right balance.

To optimise your storage costs, use real-time stock management software. This enables you to react instantly to changes in demand, avoiding unnecessary shortages and overstocking.

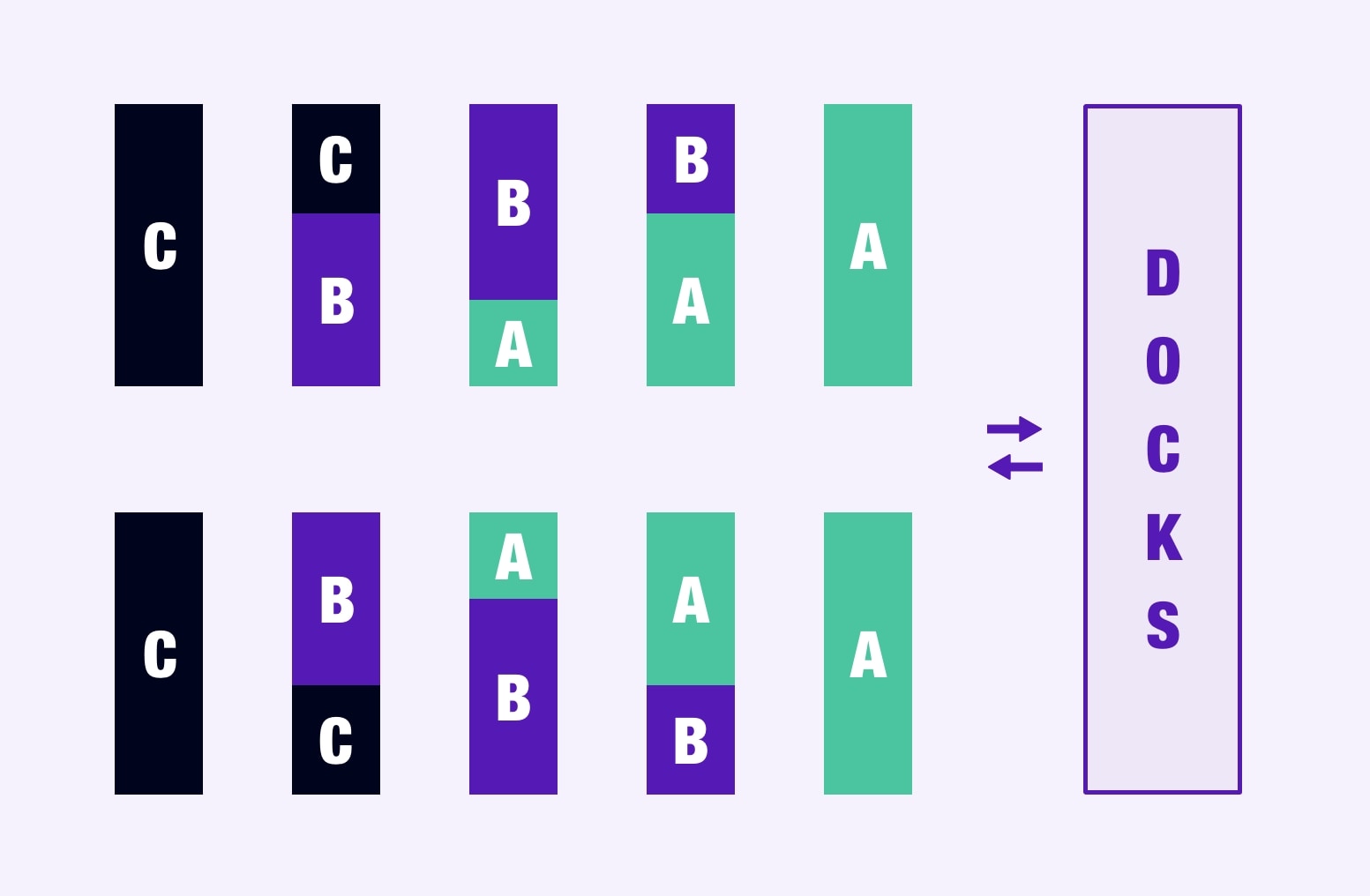

And let’s talk about warehousing methods! What about organising your warehouse to reduce order picking time and simplify the work of your operators? Here are a few options for optimising your costs:

- Activity Based Costing or ABC Inventory Method: organise your warehouse according to your company’s activities and the frequency of orders, taking into account the product turnover rate.

- First In – First Out: perfect for perishable products, this method places the oldest products close to the order picking area to ensure the best possible rotation.

- Last In – First Out: the most recent products are accessible first, which is ideal for warehouses handling seasonal products.

Don’t stop there! Think about vertical storage too, to maximise the space available! You could also consider outsourcing part of your logistics: by delegating storage, order preparation and dispatch to a dedicated platform, you could optimise your costs while enjoying peace of mind.

Activity Based Costing or ABC Inventory Method

4. Packaging Adapted to Products

Many companies overlook a simple but effective lever: maximising the filling of their packaging and containers. This strategy not only reduces logistics costs, but also cuts greenhouse gas emissions by limiting the number of journeys required.

There are three things you can do:

- Opt for robust packaging: choose sturdy materials to minimise damage during order picking. Fewer damaged products means less waste and significant savings.

- Choose made-to-measure packaging: avoid half-empty boxes that waste transport space. The right packaging optimises shipping costs and the efficiency of each shipment.

- Buy your packaging in bulk: purchasing in large quantities allows you to benefit from advantageous prices. The more you buy, the more you save, as long as your warehouse has enough storage space.

By adopting these strategies, you can turn your packaging costs into a real leverage point for your company’s profitability.

5. Automated Logistics and Warehouse Processes

To reduce your logistics costs effectively, there’s nothing like optimising your supply chain using new technologies. Software, interfaces, algorithms and data transform logistics management into a fluid, cost-effective process.

TMS (Transport Management Systems) are particularly useful. They act as virtually assistants at every stage of order delivery, organising shipments, managing supplies, optimising transit operations and even calculating CO2 emissions.

These tools provide infrastructure analysis, operational tracking of routes, comparisons between carriers, decision-making support, cost calculation and optimisation of transport routes tailored to your business. Comprehensive and rapidly indispensable, they transform your logistics management into a model of efficiency.

New technologies are helping to optimise the supply chain.

With these systems, you can generate detailed service reports on your operations as a whole, or on specific stages of the supply chain. These reports help you to easily identify areas for improvement to reduce your costs. Adopt these technologies and turn your logistics into a “well-oiled” machine!

There are also technological devices that optimise palletising, handling, packaging and much more, boosting the overall efficiency of your logistics operations. By incorporating these innovations, you’re on the road to cutting-edge logistics, ready to meet the challenges of tomorrow.

Take advantage of our software now! A 7-day free trial period is available!

WRITTEN BY

Florine Martin

Florine has been a freelance web copywriter since 2021, writing for a variety of clients in a range of sectors. Since the beginning of 2024, she has been writing articles about logistics for our company, AntsRoute.

Free 7-day trial | No credit card required

Contenu

- What is a Logistics Cost?

- The Different Types of Logistics Costs

- Inventory Management Costs

- Storage Costs

- Transport Costs

- Equipment Costs

- Labour Costs

- Packaging Costs

- 5 Ways to Reduce Logistics Costs

- 1. Optimising Last-Mile Delivery

- 2. A Good Transport Service Provider

- 3. More Efficient Stock Management

- 4. Packaging Adapted to Products

- 5. Automated Logistics and Warehouse Processes