Optimising Delivery Routes for Sensitive or Perishable Products: Challenges and Solutions

Blog > Route optimisation > Optimising Delivery Routes for Sensitive or Perishable Products: Challenges and Solutions

Optimising Delivery Routes for Sensitive or Perishable Products: Challenges and Solutions

Published on 11 December 2024 • Reading time: 8 min read

Delivering sensitive or perishable products is no ordinary task. Whether it’s fruit, vaccines or biological samples, these goods require flawless logistics. Respecting the cold chain, delivering within strict deadlines and complying with rigorous regulations are just some of the challenges that have to be met to guarantee their quality all the way to their destination.

Route optimisation is a key solution for overcoming these constraints. By combining intelligent planning and advanced technological tools, you can reduce your costs, limit your losses and ensure deliveries under the best possible conditions.

In this article, we’ll take a look at the constraints and challenges you face every day when transporting sensitive products. Through concrete examples, you’ll discover how innovative approaches, such as route optimisation, can turn your challenges into effective solutions.

Table of contents:

- Sensitive or perishable products: what are we talking about?

- The specific constraints of transporting these products

- Optimising routes: tailored solutions

- Case studies: practical examples in the food and pharmaceutical sectors

Sensitive or perishable products: what are we talking about?

So no, it’s not just vegetables and fruit, even if they are part of it.

These are all products that require very strict storage and transport conditions to preserve their quality, appearance and function.

These include food products such as fruit, vegetables, meat, fish and dairy products. Maintaining the cold chain is particularly important to prevent spoilage and bacterial growth. But this also applies to pharmaceutical products, such as vaccines, heat-sensitive medicines and biological samples. These require strict temperature control, as well as compliance with delivery times and specific transport rules.

Cosmetics, flowers and plants, chemicals and even more unexpected goods such as fragile works of art and technological equipment also come into this category.

Let’s look at these constraints in more detail.

Transport constraints for sensitive or perishable products.

What are the specific transport constraints for sensitive or perishable products?

We talked about them above. But if we sum them up, we can classify them into 3 main categories:

- cold chain compliance

- regulations

- time constraints

1. Respecting the cold chain

Respecting the cold chain is essential for sensitive products. This means maintaining a stable, appropriate temperature from collection to delivery: generally between +2 and +6°C (35.6-42.8°F) for fresh products, and down to -15°C (5°F) for frozen products.

A simple break in the cold chain, even temporary, can have irreversible consequences, such as food spoilage, loss of efficacy of medicines or contamination of biological samples.

Meeting this challenge requires specially adapted vehicles, equipped with advanced technologies such as sensors to monitor temperature in real time. It is also essential to implement strict protocols to minimise risks.

However, transporting heat-sensitive products does not always require a refrigerated vehicle; a variety of solutions exist, depending on the volume and sensitivity of the products.

- Refrigerated trucks: essential for highly sensitive products, such as frozen foods, vaccines and ultra-fresh produce.

- Isothermal packaging: ideal for small volumes or one-off deliveries, thanks to insulating materials and cold accumulators.

- Refrigerated containers: suitable for large quantities and international shipments, guaranteeing a stable temperature over long distances.

- Innovative technologies: thermal insulation films and active or passive packaging, limiting the need for costly equipment.

2. Regulations

The transport of sensitive products is governed by strict standards, which vary depending on the product category. For example, food products must comply with the HACCP method (Hazard Analysis and Critical Control Points), while pharmaceutical products follow Good Distribution Practice (GDP) and laboratory samples comply with standard ISO 15189 Medical laboratories — Requirements for quality and competence.

The regulations require regular audits, detailed documentation and full traceability throughout the supply chain. Non-compliance can lead to legal sanctions, product recalls or loss of customer confidence.

Refrigerated transport is also subject to the ATP Agreement (Agreement on the International Carriage of Perishable Foodstuffs and on the Special Equipment to be used for such Carriage). This international agreement, signed by 48 countries, sets out the requirements for temperature-controlled transport, including the thermal performance of vehicles and the periodic inspections to be carried out.

Traceability of logistics operations is the key to ensuring regulatory compliance.

3. Time constraints

Perishable products, by definition, have a limited lifespan, which means that delivery times have to be particularly tight and precise. For example:

- Fresh food products: Fruit, vegetables, meat or fish can lose their freshness or become unfit for consumption if delayed, especially if they are not transported under optimum conditions.

- Pharmaceutical products: Vaccines, heat-sensitive medicines and blood samples must be delivered quickly to guarantee their effectiveness and meet critical needs, particularly in hospitals.

These tight deadlines require:

- Precise route optimisation: Using planning software that takes account of traffic, weather conditions and multiple delivery points to reduce journey times.

- Proactive contingency management: Plan alternative routes in the event of traffic jams, breakdowns or other hazards.

- Smooth synchronisation of operations: Perfect coordination between warehouses, carriers and recipients to minimise waiting times at different points in the supply chain.

Accuracy is as essential as speed. Out-of-time delivery can lead to refused goods, financial loss or, in the case of blood sampling, damage to samples, delaying diagnosis and treatment.

The delivery of sensitive products must meet specific constraints.

Optimising routes for sensitive and perishable products: multiple challenges

To meet the logistics challenges of sensitive or perishable products, there is a wide range of solutions, from advanced technological tools to innovative planning approaches. The aim is to ensure traceability and deliver in the best possible time and conditions, while optimising costs.

Let’s take a look at what these tools are and what they can do for you:

1. Reducing costs and losses: the importance of effective planning

Optimised planning minimises distances travelled, avoids empty runs and makes better use of available resources. This results in:

- Financial savings: optimised routes reduce fuel consumption, wear and tear on vehicles and overtime.

- Less waste: Sensitive or perishable products arrive on time, in conditions that preserve their quality, avoiding losses due to missed deadlines or breaks in the cold chain.

- Guaranteed traceability: Thanks to technological tools, each stage of transport can be monitored in real time, guaranteeing complete visibility of delivery conditions (temperature, location, deadlines). This transparency not only improves logistics management, but also boosts the confidence of customers and partners.

Efficient planning of deliveries of sensitive products reduces costs and losses.

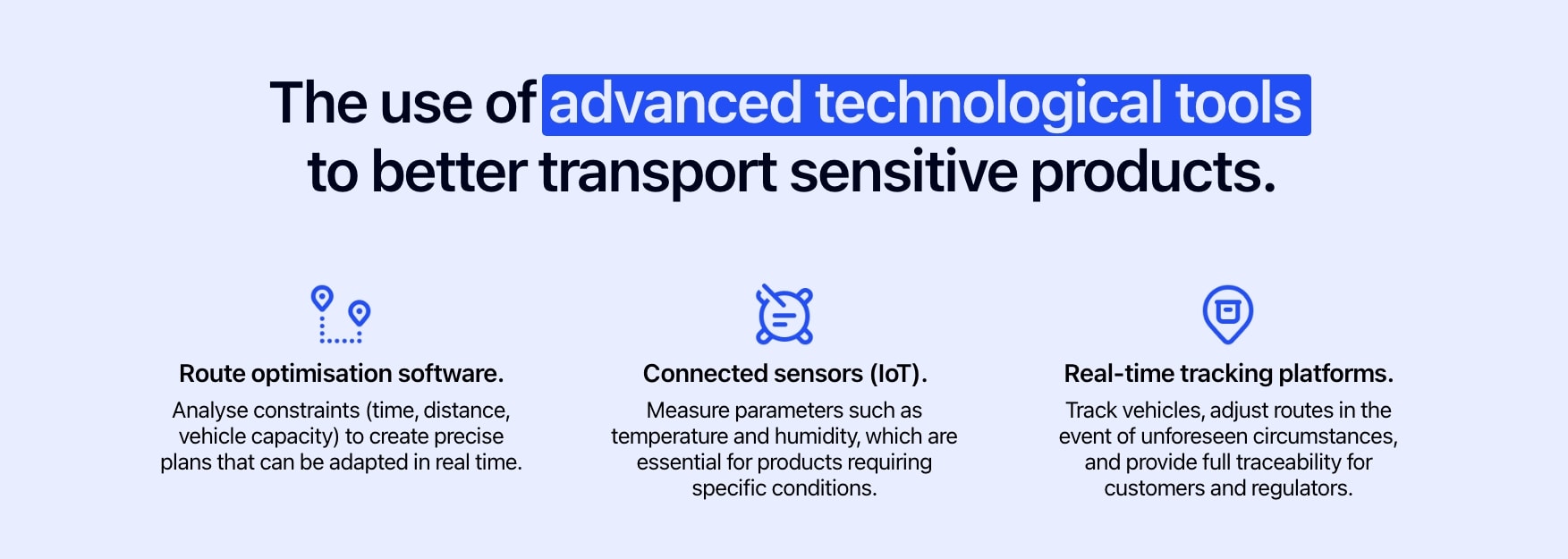

2. Using advanced technological tools: innovating for better transport

Technology plays an essential role in route management, with solutions tailored to the different challenges:

- Route optimisation software: This analyses constraints (time, distance, vehicle capacity) to create precise plans that can be adapted in real time.

- Connected sensors (IoT): These devices measure and monitor parameters such as temperature and humidity, which are essential for products requiring specific conditions, such as medicines or frozen foods.

- Real-time tracking platforms: These allow vehicles to be tracked, routes to be adjusted in the event of unforeseen circumstances, and provide full traceability for customers and regulators. These functions can be integrated into route optimisation software.

Advanced technological tools enable sensitive products to be transported more efficiently.

Let’s take a look at the practical benefits of route optimisation software for the transport of sensitive and perishable products. To do this, we’ll look at:

- on a fictitious case of fruit and vegetable delivery for a supermarket chain,

- and a real case of using AntsRoute software to collect biological samples for around thirty medical analysis laboratories.

Practical examples of transporting sensitive and perishable products in the food and pharmaceutical sectors

Food sector: Delivery of fruit and vegetables for a supermarket chain

Specific constraints:

- Short delivery times: In the food sector, the delivery of fresh produce such as fruit and vegetables is particularly demanding. These goods have to arrive within very short timescales to preserve their freshness and quality, while meeting the delivery deadlines imposed by supermarkets.

- Avoidable costs: Poor planning can lead to delays or unnecessary mileage, increasing logistics costs and the risk of wastage.

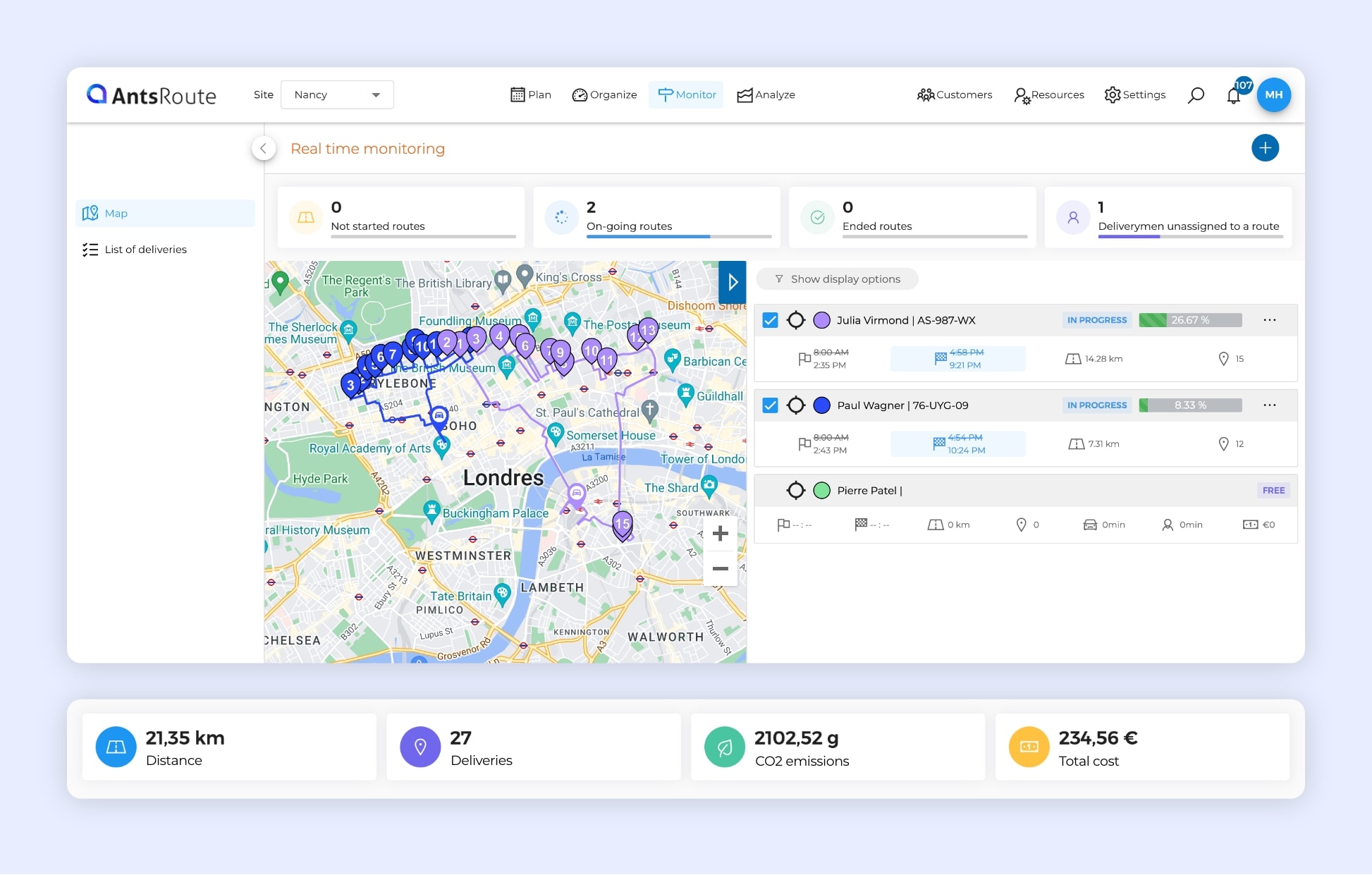

Solution: With a route management tool like AntsRoute, routes are optimised according to a number of parameters:

- The geographical location and reception times of the shops.

- The volumes to be transported and vehicle capacity.

- Real-time traffic, to avoid traffic jams.

- The delivery times to be respected and the specific constraints linked to the products.

Thanks to this optimisation, a fruit and vegetable supplier can reduce fuel costs and improve the number of on-time deliveries. Products arrive in perfect condition to be put directly on the shelves, with no losses due to missed deadlines or poorly planned journeys.

Optimising delivery routes using AntsRoute.

Pharmaceutical sector: Transport of blood samples for SYNLAB

In the medical field, logistics play a fundamental role in guaranteeing the quality of analyses. Every day, the SYNLAB Nouvelle-Aquitaine group collects biological samples from over 30 collection points to serve its 26 laboratories.

Specific constraints:

- Compliance with critical deadlines: Each sample must be transported at a controlled temperature within a specific period of time after collection to avoid any deterioration and to ensure timely analysis.

- Multi-site planning: Collections must be organised in an optimised order, taking into account emergencies, the constraints of healthcare professionals and the availability of technical facilities.

- Tracking and traceability: Full traceability is essential to ensure regulatory compliance with ISO 15189 and to keep patients informed.

All routes must be completed in less than 2 hours 30 minutes, to take account of the inevitable contingencies.

Solution: Synlab Nouvelle-Aquitaine has chosen AntsRoute’s software to effectively manage these constraints:

- Routes are planned to minimise the distances covered and maximise delivery times.

- Couriers receive precise routes and real-time updates in the event of unforeseen circumstances, such as unfavourable traffic conditions or emergencies that need to be added to the schedule.

- Every stage of collection and delivery is tracked using an intuitive interface. So any incident or delay can be easily documented.

The result is rapid, secure collection, ensuring that blood samples reach laboratories in optimum conditions for accurate analysis and in compliance with current standards.

These case studies show how tools such as AntsRoute’s route optimisation software can meet the specific challenges of the food and pharmaceutical sectors. By optimising routes, companies transporting sensitive or perishable products can reduce costs, minimise losses and guarantee a reliable service: an essential element in building customer loyalty and maintaining competitiveness.

WRITTEN BY

Maryline Lakh

Maryline worked for a major logistics company for 15 years. Since 2022, she has been an expert in communication and freelance writer for positive-impact logistics companies. She is passionate about new sustainable logistics solutions and writes for several clients, including AntsRoute.

Free 7-day trial | No credit card required

Contenu

- Sensitive or perishable products: what are we talking about?

- What are the specific transport constraints for sensitive or perishable products?

- 1. Respecting the cold chain

- 2. Regulations

- 3. Time constraints

- Optimising routes for sensitive and perishable products: multiple challenges

- 1. Reducing costs and losses: the importance of effective planning

- 2. Using advanced technological tools: innovating for better transport

- Practical examples of transporting sensitive and perishable products in the food and pharmaceutical sectors

- Food sector: Delivery of fruit and vegetables for a supermarket chain

- Pharmaceutical sector: Transport of blood samples for SYNLAB