Last-mile logistics is evolving!

Last-mile logistics is a key element in the supply chain. At a time when we are talking about sustainable logistics, optimising routes and reducing carbon emissions, it is particularly important. Whether you’re a carrier or a prime contractor, here’s a look at how it works, the issues and the current solutions available to help you keep costs low and preserve the environment.

In this article, we’ll look at:

- The definition and recent development of last-mile logistics.

- The 8 challenges it faces.

- The emerging solutions for efficient, cost-effective and more environmentally-friendly deliveries.

Last-mile logistics is a key element in the supply chain. For e-commerce operators and transport professionals, optimising the last mile is essential to keep costs down and protect the environment.

What is last-mile logistics? 5 processes not to be overlooked

Last-mile logistics is often confused with e-commerce deliveries to the final recipient. But it’s much more than that!

It covers all logistics activities linked to the final stage of the supply chain, from the distribution centre or last place of storage, to the final recipient. This may be a consumer (BtoC or CtoC), a business or retail outlet (BtoB) or a pick-up point (BtoBtoC). It may be located in an urban, rural or peri-urban area.

Last-mile logistics includes at least 5 logistics processes:

1. Final storage

It involves managing stocks and goods at the last distribution centre or warehouse, before delivery to customers. It is possible to deliver directly from the customer’s production site or warehouse, at a distance from the city. But it is becoming increasingly judicious to consolidate orders before final delivery, to reduce costs and limit the impact of individual deliveries.

New types of warehousing are emerging to deal with this:

- Logistics hubs, urban logistics areas or flow concentration centres are increasingly being implemented at the entrance to or within towns, to pool orders before delivering them. They are designed for retailers, hauliers, wholesalers and bicycle logisticians.

- In recent years, we have also seen the creation of pedestrian drives or darkstores in city centres: these are enclosed premises in city centres used to store, prepare and deliver everyday consumer goods ordered over the internet.

- Sogaris, which is in charge of developing the urban logistics in Paris, has also been experimenting for a year with micro-hubs in the heart of Paris. These units are placed in parking spaces and are easy to move around. They can be used to temporarily store small boxes for goods deliveries, so that cargo bike drivers don’t have to make many return trips. The experiment ended this summer, but could be extended to other french cities.

2. Delivery to multiple locations

With the boom in e-commerce orders over the last few years, the number of delivery points has increased in BtoC: home delivery, but also delivery to a pick-up point, pick-up locker, at a neighbour’s house, at the post office or even in-store with Click and Collect.

In the BtoB sector, last-mile logistics involves supplying stocks to the different physical shops or delivering orders from other companies. Some customers also choose to keep stock on their premises.

Different services can also be offered, such as express delivery, delivery at fixed times, evening delivery, delivery on Sundays, goods collection, etc. Each type of service has its own constraints and logistics requirements, but can provide real added value for the consumer.

The number of BtoC delivery points is increasing.

3. Management of returns

Last-mile logistics can no longer overlook this important part of e-commerce.

The return rate was 16.6% in the United Kingdom in 2021. But the rate continues to grow. In addition, there are growing obligations to recycle paper, cardboard and other materials, and soon bio-waste.

This is a significant cost factor for companies. By linking it to last-mile deliveries, you can avoid empty returns and keep costs down.

4. Optimisation of routes

The planning of routes is also an essential aspect of last-mile logistics. It involves determining the best possible route to deliver packages efficiently, minimising the distances travelled and avoiding delays.

5. Tracking and traceability

Last-mile logistics also require precise tracking and tracing of shipments in real time. The carriers need to be able to track parcels at every stage of the delivery process, to provide reliable information to customers. This is particularly important for refrigerated or sensitive products, such as medicines. It also has a major impact on customer satisfaction, and therefore plays a significant role in building customer loyalty.

The 8 challenges of last-mile logistics

The last mile is often the most complicated and costly phase of the logistics process. It accounts for 40-55% of total supply chain costs. It involves specific constraints:

1. Lack of space, traffic jams and imposed regulations

Highly populated city centres make it difficult to complete deliveries and set up urban storage areas. In addition to traffic jams and a lack of parking space, regulatory constraints are gradually restricting access to town centres for more polluting vehicles. 8 cities have introduced a Low Emission Zone (LEZ) and 6 other towns should do so in the next few months. Access to these zones is gradually being restricted to polluting vehicles 24 hours a day, seven days a week, every day of the year.

2. Fragmentation of orders and multiplication of delivery points

The value of online retail sales in the United Kingdom jumped from 69.71 billion GBP in 2018 to almost 120 billion in 2021. Although sales have fallen by 15 billion in 2022 compared to the previous year, they are still at a very high level. This boom in online shopping has led to an explosion in deliveries of small, single packages to multiple destinations.

These deliveries are particularly complicated to optimise, especially in rural areas, where there are long distances between the locations to be delivered.

3. Customer demands for fast delivery

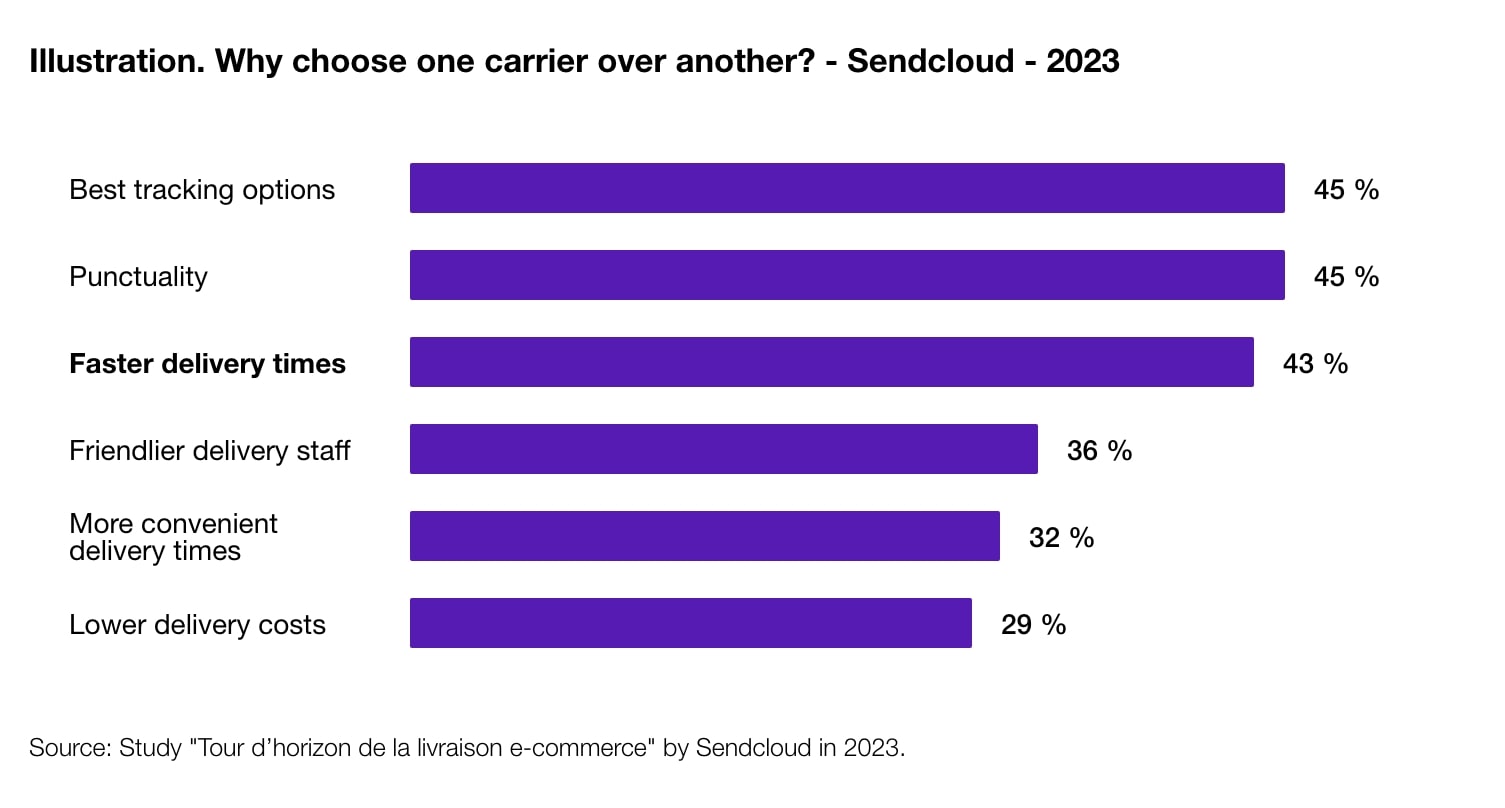

With the rise of e-commerce, consumers have become increasingly demanding. Fast delivery has become the norm. According to a study by SendCloud in 2023, Europeans wait an average of 3.4 days for delivery, and would not be prepared to wait more than 5 days.

Although ultrafast delivery experts (Gorillas, Getir and Zapp) have been experiencing serious difficulties in recent months, 40% of European consumers would still like to benefit from very fast delivery services for their online orders (delivery in a few minutes to a few hours). However, more than 50% are hoping for more environmentally-friendly deliveries, which are difficult to achieve with express deliveries.

The expectations of consumers are therefore contradictory. But it is certain that they are used to being supplied on demand. And it is these demands that last-mile logistics providers and carriers have to meet, in order to satisfy the requirements of retailers and end customers. If delivery takes too long, 45% of shopping baskets are abandoned.

“Overview of e-commerce delivery” study carried out by Sendcloud.

4. Imposed delivery time and services

Consumers also have requirements in terms of delivery times. Companies obviously want delivery during office or shop opening hours. But according to the same SendCloud study, the French would prefer delivery between 6pm and 8pm, or delivery to a pick-up point (34%). 21% of Europeans would like weekend delivery and 31% want scheduled delivery.

All these requirements must also be met, to avoid delivery failures, which is a very high logistics cost.

5. Storage, transloading and preservation issues

From final storage to delivery to the consumer, there can be several stages and modes of transport: preparation, palletisation, labelling, consolidation, transport by HGV, commercial vehicle, cargo bike, etc. The containers change, but the transport must remain safe, without any change in temperature or damage to the goods being shipped. That’s a challenge in itself. At the same time, we have to make sure that the transport vehicles are sufficiently full to ensure cost-effective deliveries.

6. Shortage of delivery drivers and rising energy costs

For the younger generation, the job of delivery driver is not the dream job, and the shortage of drivers has worsened in recent years. To attract and retain reliable, qualified staff, it is often necessary to increase wages or offer extra benefits. On top of this, the cost of energy is still very high, and investment in vehicles that are less polluting and more suited to city driving is required. It’s not easy to make a profit from your transport business. That’s why it’s once again important to fill your vehicles properly, optimise your routes and train your drivers well enough to keep the number of kilometres you cover, fuel consumption and CO2 emissions to a minimum!

7. Need to reduce CO₂ and fine particle emissions

These figures are no longer unknown: around 20% of greenhouse gases and 50% of urban fine particle emissions are due to goods transportation. Not to mention the noise pollution, road congestion and delays caused by delivery drivers.

There are more and more regulations to reduce this pollution, by restricting the most polluting vehicles and encouraging more eco-friendly modes of transport that respect urban life: development of Low Emission Zone, plan to encourage cycling, etc.

These are therefore also important factors to take into account when organising your last-mile logistics.

8. Reducing packaging and taking returns into account

The impact of packaging on transport costs and CO2 emissions is often overlooked.

The packaging helps to ensure the safety of the product being shipped, so it should not be overlooked. But overpackaging and poorly adapted packaging mean that we are transporting “empty”, with all the consequences in terms of cost. Not to mention the fact that packaging is often thrown away immediately after use.

The choice of packaging is not a matter for the carrier. But by charging for transport based on the volume of goods carried, rather than just the weight, it is possible, as a carrier or contractor, to send its customers a direct message to reduce packaging. Not to mention the fact that over-packaging is not good for customer satisfaction, as customers are increasingly looking for packaging that is adapted to their needs, and even recyclable.

The transport of this recyclable packaging, like the returned goods, can also become an interesting service, to limit empty return transport and therefore minimise costs.

What are the solutions for more cost-effective and environmentally-friendly last-mile logistics?

We have already mentioned a number of possibilities in previous sections.

- The development of logistics hubs or consolidation centres and the pooling of orders prior to final delivery, to limit the number of single deliveries.

- Combining returns with last-mile deliveries to reduce empty mileage.

- The use of bicycle logistics for easier access to urban areas, with less pollution. This “new” delivery method is encouraged by the governments and partially subsidised by programmes. It can be combined beforehand with other road, river or rail delivery methods.

- Invoicing by volume rather than weight, to reduce packaging and transport more goods at once.

- Training drivers in eco-driving, customer follow-up and route optimisation, to reduce mileage and fuel consumption and improve customer satisfaction.

- The introduction of freight corridors, night deliveries and additional delivery slots is also being tested in a number of cities, to limit urban congestion.

In a second article dedicated to last-mile delivery, we propose additional solutions: encouraging out-of-home delivery, turning home delivery into an unforgettable experience, converting delivery vehicle fleets to low-carbon vehicles, and so on.

It is important to meet consumer demands in terms of delivery and tracking. In particular, this helps to limit delivery failures, which is a very high logistics cost. But not all customers demand fast delivery, and more and more of them are hoping for more environmentally-friendly deliveries. Slower deliveries and out-of-home deliveries are easier to pool and can therefore reduce costs. By clearly displaying the cost and environmental impact of the transport offered, both as a retailer and as a carrier, it is possible to encourage consumers to choose slower, greener and cheaper deliveries.

But the best way to reduce costs and emissions is to optimise routes. It plays a central role in improving the efficiency of last-mile logistics. It allows goods to be delivered more quickly, avoids delivery delays, limits the number of vehicles required and reduces the number of kilometres travelled and therefore the CO2 emissions per parcel shipped. And here there are no secrets: the human touch has its limits, and the use of data and software is becoming indispensable.

That’s what we offer at AntsRoute: software that plans your deliveries, optimises vehicle capacity and routes, tracks all your shipments, allows you to make appointments, and notifies customers throughout the delivery journey. It is available from 12 euros per month per vehicle.

Last-mile logistics is being reinvented to meet today’s challenges: ensuring more sustainable, earth-friendly logistics, while limiting carrier costs and meeting consumer needs. It’s an unstable and perilous equation. But a number of measures are being taken to address it, each at its own level. Route optimisation is an essential lever for achieving these objectives, enabling transport operators and principals to meet customer expectations while helping to protect the environment. Embracing these technological advances and adopting a collaborative approach are two essential keys to success!

Free 7-day trial | No credit card required

Contenu

- What is last-mile logistics? 5 processes not to be overlooked

- 1. Final storage

- 2. Delivery to multiple locations

- 3. Management of returns

- 4. Optimisation of routes

- 5. Tracking and traceability

- The 8 challenges of last-mile logistics

- 1. Lack of space, traffic jams and imposed regulations

- 2. Fragmentation of orders and multiplication of delivery points

- 3. Customer demands for fast delivery

- 4. Imposed delivery time and services

- 5. Storage, transloading and preservation issues

- 6. Shortage of delivery drivers and rising energy costs

- 7. Need to reduce CO₂ and fine particle emissions

- 8. Reducing packaging and taking returns into account

- What are the solutions for more cost-effective and environmentally-friendly last-mile logistics?