Industrial laundries: when performance depends on smart logistics

Every morning, well before dawn, industrial laundry trucks crisscross the roads. In their containers: tons of hospital sheets, hotel towels, and workwear, all ready to be restored to whiteness and cleanliness before being delivered again just a few hours later. Behind this finely tuned choreography lies a discreet but essential link in the economy: the rental and maintenance of textile items, a B2B sector that keeps healthcare, hospitality and catering, and industry running smoothly.

But this well-oiled machine relies on a fragile balance. Between soaring energy costs, labor shortages, and ever-increasing customer expectations, logistics have become a real day-to-day challenge. What if the key to competitiveness were actually found there, on the road? In this business where everything is constantly turning (linen, vehicles, and schedules), performance now depends on smarter logistics, driven by digitalization and optimized delivery routes.

The sector in a few key figures:

- €1.3 billion in annual revenue in the UK in 2022

- +5.8% annual growth expected until 2030, driven by the post-Covid recovery

- 22,000 to 28,000 employees, a large share of whom are delivery drivers

- ~56% of revenue generated with the hotel and restaurant sector

- ~16% of revenue generated with the healthcare sector

- ~18% of expenses are devoted to transport and energy

Table of contents:

- A solid sector, but under logistical pressure

- Between dirty linen and clean linen: the fragile balance of logistics

- Delivery drivers, the silent pillars of performance

- AntsRoute: Digitising routes to keep costs under control

- RFID + AntsRoute: the new era of connected laundries

- Logistical excellence: a lasting competitive edge

A solid sector, but under logistical pressure

The market, estimated at €1.3 billion in 2022, is in good shape: it is growing by 5.8% per year, driven by the recovery in tourism and the outsourcing of laundry by healthcare facilities and hotels. But behind this apparent dynamism, the reality on the ground is much more mixed:

- Increase in gas and electricity prices.

- Shortage of labour, particularly among delivery drivers.

- Price pressure exerted by major clients.

And in this already fragile equation, transport carries significant weight: on its own, it accounts for nearly 8% of expenses, and up to 18% when including water and energy costs. Every unnecessary detour, every minute lost in traffic jams or rescheduling a route eats away at profitability.

“Logistics is our lifeblood,” sums up Marc, the head of a regional laundry. “Every unnecessary detour, every minute spent waiting on the road is fuel burned and time lost.”

Faced with these constraints, leaders in the sector know that every optimised kilometre becomes a direct lever for profitability. This is where digital transformation truly comes into its own.

Industrial laundries: key figures for the sector.

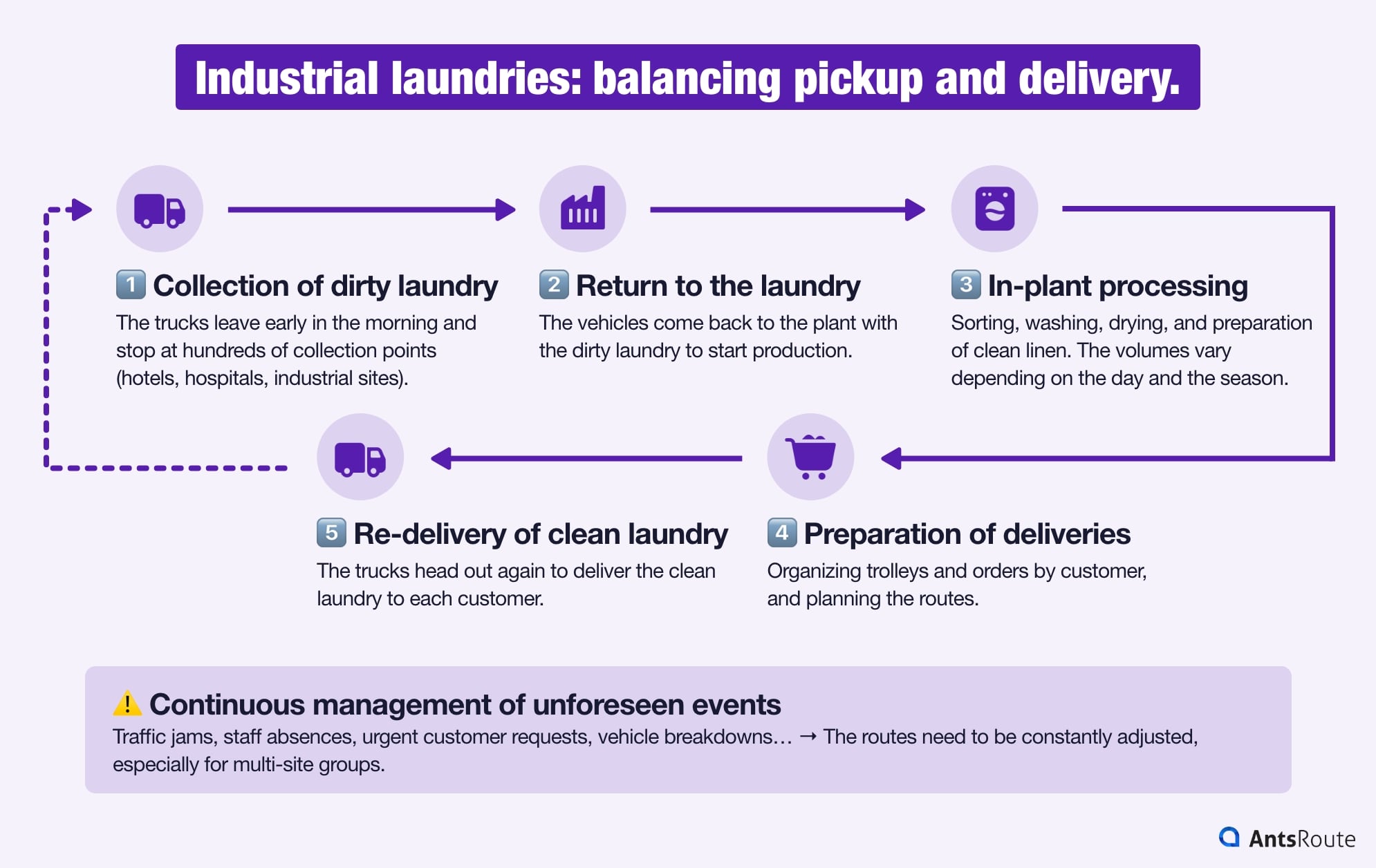

Between dirty linen and clean linen: the fragile balance of logistics

In an industrial laundry, everything begins and ends on the road. Trucks leave at dawn to collect dirty linen, then head back out a few hours later to deliver the clean linen. This bidirectional flow, which is the true backbone of the business, must be perfectly synchronised: you can’t deliver to a hotel if the linen hasn’t been washed, and you can’t start production without the trucks returning.

This model, simple in appearance, is based on a complex logistics equation:

- Hundreds of collection and delivery points

- Laundry volumes that vary by day and by season

- Strict time constraints in hospitals and nursing homes

- Drivers subject to road transport regulations

To this are added the realities on the ground: traffic jams, last-minute absences, urgent requests, or vehicles out of service. Manually planning then becomes a real headache, especially for multi-site companies.

The major players on the market (Elis and Johnson Service Group PLC) have understood this well: their advantage no longer lies only in the quality of the washing, but in their command of logistics. Because in the end, the customer doesn’t see the machines, they see the driver.

Industrial laundries: balancing collection and delivery.

Delivery drivers, the silent pillars of performance

While the machines are running at full capacity in the plants, customer service is played out in the field. Behind the wheel of their trucks, delivery drivers are the shop window of industrial laundries. They are the ones who ensure consistency, punctuality, and quality of service, as close as possible to the client. A successful route is a promise kept: a hotel that can change its sheets on time, a hospital that has sterile gowns available, a workshop that gets its clean uniforms back.

But the profession is struggling and faces a double challenge: demanding working conditions and staff shortages. Between handling heavy loads, irregular hours, and repetitive routes, the industry is finding it hard to recruit. Vacant positions are multiplying, and logistics managers have to juggle tight schedules, last-minute absences, and non-negotiable delivery constraints on a daily basis.

This is where technology once again comes into play, more specifically, our AntsRoute software. It helps rebalance workloads, avoid duplicate trips, and automatically redistribute routes in the event of unforeseen circumstances. A driver off sick? The software adjusts the routes. An urgent customer request? The route is recalculated instantly, without having to start everything from scratch.

In the field, drivers use an intuitive mobile app that centralises all their tasks for the day. In just a few taps, they can:

- View their route sheet

- Launch integrated GPS navigation

- Validate each stop with proof of delivery (photo, signature, or PIN code)

☝️ Result: less stress for teams, greater visibility for managers, and a smoother customer service experience.

A delivery driver handles the distribution of clean laundry for an industrial laundry facility.

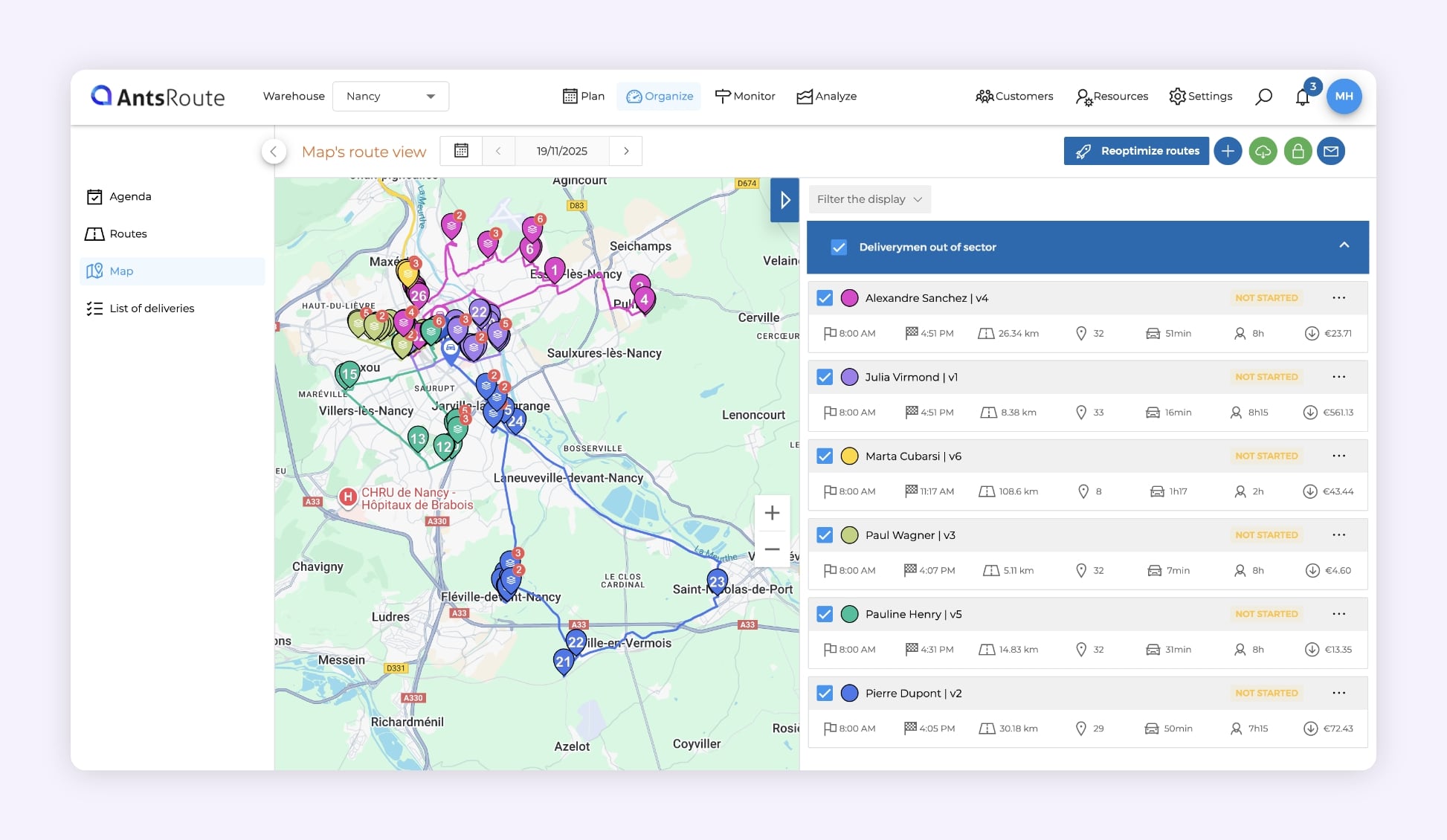

AntsRoute: Digitising routes to keep costs under control

The numbers speak for themselves: as mentioned above, transport represents a significant share of the budget. In this context, every kilometre saved directly improves profitability. AntsRoute makes it possible to turn this cost item into a driver of long-term efficiency:

Reduce costs and carbon footprint:

- The algorithm calculates the shortest and most efficient routes based on real-world constraints (customer time windows, traffic, low-emission zones), which significantly reduces the number of kilometres travelled and directly cuts fuel costs.

- Fewer kilometres travelled = less fuel consumed = lower CO₂ emissions.

- Planners also save valuable time: no more spreadsheets and manually adjusted schedules.

Boost productivity and peace of mind:

- Better use of the existing fleet without overloading teams.

- The software automates complex planning tasks, synchronises data in real time between the field and headquarters, and provides each driver with a clear and realistic route plan.

“Before, it took two hours to redo a schedule when someone was absent,” says Marc. “Today, everything is recalculated automatically. We save time, fuel, and peace of mind.”

Stand out through quality of service

In a market where reliability is king, logistics quality becomes a major commercial selling point. With AntsRoute, laundries gain in:

- Punctuality, thanks to optimised routes

- Flexibility, with instant adaptation to unforeseen events

- Transparency, via precise delivery data and proof of visit

The AntsRoute route optimization software.

RFID + AntsRoute: the new era of connected laundries

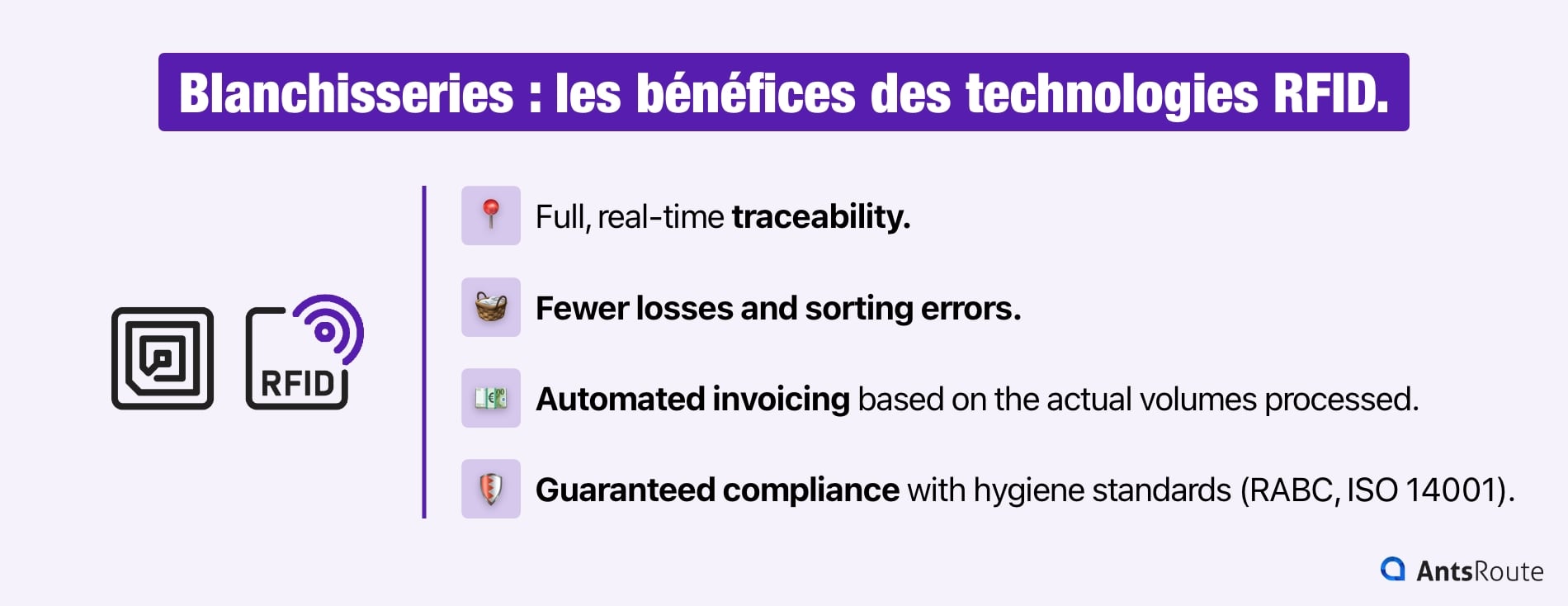

The other small revolution in the sector is textile traceability thanks to RFID (Radio Frequency Identification) technology. Every sheet, gown, or uniform equipped with an RFID tag is tracked throughout its entire lifecycle, from collection to return to the customer.

The benefits are tangible:

- Full, real-time traceability.

- Fewer losses and sorting errors.

- Automated invoicing based on the actual volumes processed.

- Guaranteed compliance with hygiene standards (RABC, ISO 14001).

Combined with AntsRoute, RFID creates an intelligent, connected logistics chain:

- RFID data provides accurate information on the volumes to be collected or delivered.

- AntsRoute uses this data to plan routes as precisely as possible.

- Deliveries become more accurate, stock is better managed, and customer satisfaction is strengthened.

A winning duo, especially in the hospitality and healthcare sectors, which together account for over 70% of the market and demand an impeccable level of service.

Illustration showing the 4 benefits of RFID tags for textile traceability.

Logistical excellence: a lasting competitive edge

Today, customers (hospitals, nursing homes, hotels, industry) demand flawless punctuality, full traceability, and immediate responsiveness. One delay, one mistake, one incomplete delivery, and the entire chain is shaken. That’s why mastering logistics has become a commercial argument in its own right. Certifications such as RABC (Risk Analysis and Biocontamination Control) or ISO 14001 require rigorous tracking of routes, lead times, and proof of delivery, which is a level of traceability that only digital tools like AntsRoute can guarantee.

“Our competitiveness no longer depends solely on our machines, but on our ability to deliver accurately, on time, and with complete transparency,” Marc points out.

In industrial laundries, everything begins and ends on the road.

And that’s where everything is decided: the difference between a profitable business and one that’s struggling.

Optimising routes isn’t just about saving money: it’s about taking back control of your operations, reducing driver fatigue, strengthening customer satisfaction, and speeding up the ecological transition. With AntsRoute, this transformation becomes simple, tangible, measurable, and just a click away. Don’t wait any longer to try AntsRoute free for 7 days!

➡️ Check out our pricing.

➡️ Request a free demo or contact our team to learn more about our solutions for industrial laundry professionals.

WRITTEN BY

Florine Martin

Florine has been a freelance web copywriter since 2021, writing for a variety of clients in a range of sectors. Since the beginning of 2024, she has been writing articles about logistics for our company, AntsRoute.

Free 7-day trial | No credit card required

Contenu

- A solid sector, but under logistical pressure

- Between dirty linen and clean linen: the fragile balance of logistics

- Delivery drivers, the silent pillars of performance

- AntsRoute: Digitising routes to keep costs under control

- RFID + AntsRoute: the new era of connected laundries

- Logistical excellence: a lasting competitive edge