Delivery optimisation – How can software help you?

You manage a goods delivery or transport company. Or you regularly use the services of transport companies to deliver to your shops and customers.

Fuel prices have stabilised. But the inflation rate is still very high. The vehicle maintenance and repair costs are rising faster than the prices charged by the principals. It is becoming increasingly difficult to find delivery drivers and to retain them. Your employees or service providers are asking you to pay them more to offset these costs. And now there are the added constraints of low-carbon transport. It’s a vicious circle!

However, there is a way of limiting your goods transport costs and your need for vehicles and workforce: it’s by optimising your deliveries. And much of this can be done with the help of software and its algorithms.

Table of contents

- How can you optimise your parcel and goods deliveries?

- The 5 benefits of software to optimise the delivery of your goods

To reduce costs, delivery optimisation is the answer to today’s economic challenges. Thanks to software algorithms, goods transport companies are able to manage their resources more effectively and minimise operational expenses.

How can you optimise your parcel and goods deliveries?

Optimising means offering the best possible conditions of use, operation, and performance. This means increasing your profitability, but also improving the organisation and efficiency of your deliveries.

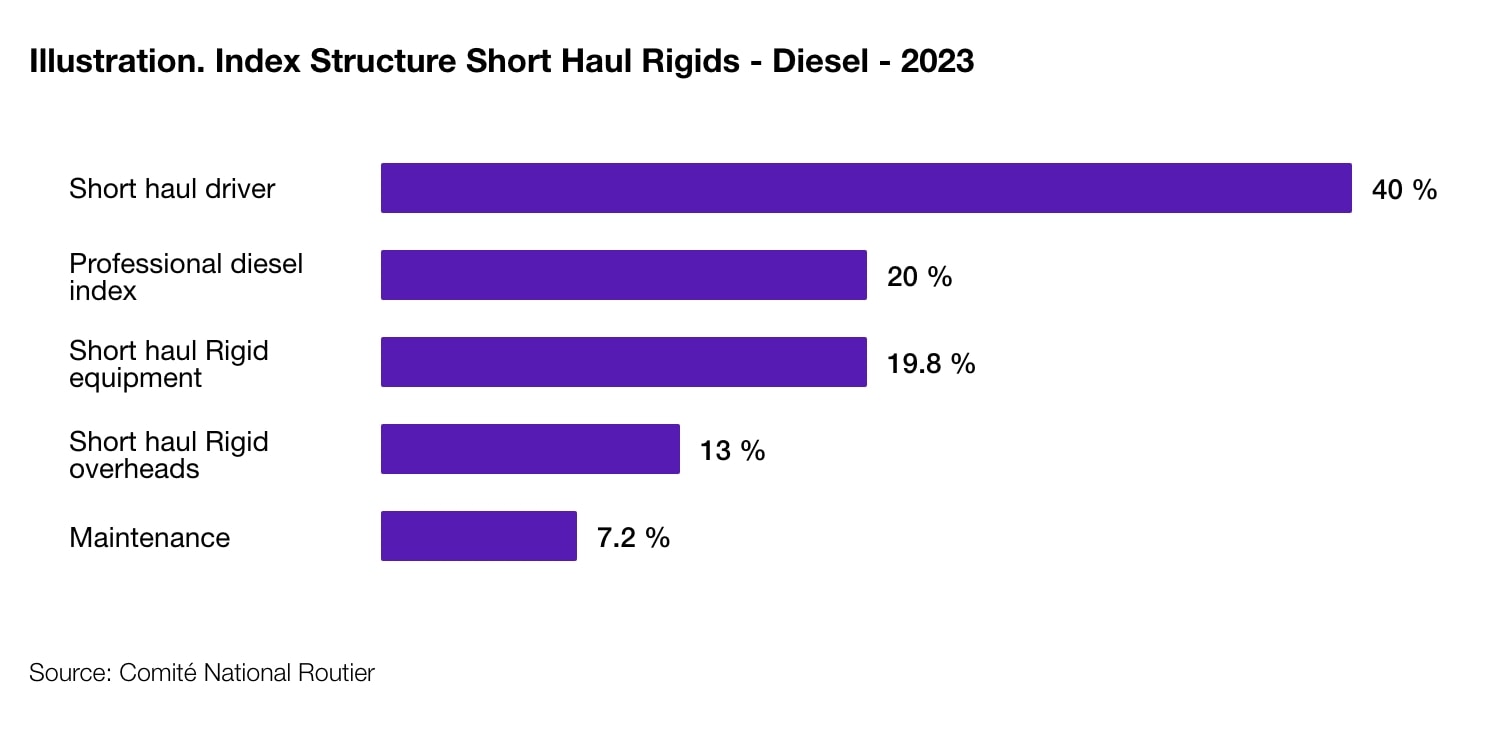

According to the Comité National Routier, which is a technical body whose mission is to observe the operating methods of road transport markets, the drivers’ wages (and expenses), fuel and maintenance costs account for around 70% of road transport costs. The remaining 30% relates to structural and equipment costs.

The breakdown of costs for the road transport of goods.

Like many freight forwarders or transport companies, your number one priority is certainly to reduce your operating costs.

But it’s difficult to cut costs without compromising customer and employee satisfaction. If your vehicles are older or not properly maintained, you run the risk of regular breakdowns, longer downtimes and, ultimately, additional costs and delivery delays. And saving on your drivers’ wages won’t help you retain them.

Switching to electric vehicles is not easy either, as purchase prices are still high and infrastructure is limited.

You still have 4 other ways of optimising your deliveries and reducing your costs.

- Reduce the number of miles driven and CO2 emissions: By optimising your routes, you can have your delivery staff drive fewer miles or deliver more packages in one day. This will reduce fuel costs, wear and tear on your vehicles, CO2 emissions and parcel delivery times.

- Optimise the sequencing and fill rate of your vehicles: It is often possible to load more packages onto the same vehicle, taking into account their volume and the order in which they are to be delivered. This reduces the number of vehicles needed and the unloading time required.

- Boost the success rate of first delivery attempts and quality of service: Your delivery drivers waste precious time trying to deliver packages to customers a second time if they are absent on the first visit. If you succeed in optimising the first delivery rate, you’ll once again save on miles travelled and working time. By improving the quality of your service, you’ll also build customer loyalty and attract new prospects.

- Improve working conditions and staff loyalty: As you know, recruiting and training new staff is both costly and time-consuming. By making your drivers’ work easier, you’ll also be able to improve their loyalty, while keeping their wages constant.

The 4 ways of optimising your deliveries.

Improving the efficiency of your routes will therefore help you both to reduce your costs and to improve the satisfaction of your customers and your drivers.

You’ve certainly tried to optimise all these factors yourself and improve the organisation of your deliveries. But you’ve probably come up against a major limit: the amount of data you need to manage in order to optimise routes, schedules and vehicle capacity.

That’s where digital technology comes in, offering you relevant ways of optimising operations that are very difficult to do manually.

The 5 benefits of software to optimise the delivery of your goods

It’s always possible to create simplified itineraries using an Excel spreadsheet and navigation tools like Google Maps or Waze.

But we’re not always aware of the invaluable help that business digital tools can provide. To help you do just that, we’ve listed the main features of software tools dedicated to optimising freight transport.

1. Automated sorting and sequencing of orders

The first optimisation stage is rarely the responsibility of the carriers. It takes place before the delivery process, in the distribution centres or supplier warehouses. It involves sorting, placing on pallets and sequencing orders in the best possible order.

More and more companies are using automated package sorting, processing and palletising systems to speed up these logistics operations. This eliminates manual steps, reduces processing errors, speeds up the flow of parcels through distribution centres, and allows transport vehicles to be loaded in the right order. At this stage, customer data goes from databases (ERP) to warehouse management software (WMS) to transport software (TMS).

The automated sorting of orders in warehouses.

2. The optimisation of vehicle loading

The next step is to place the goods in the transport vehicles, to optimise the space available and reduce the number of vehicles required. Here again, software can be a great help. Using advanced algorithms, some software automatically calculates the best possible layout, based on the sequencing order provided, the size of the packages and the storage space available.

This means more parcels delivered by a single vehicle, and therefore less fuel consumed and CO2 emissions.

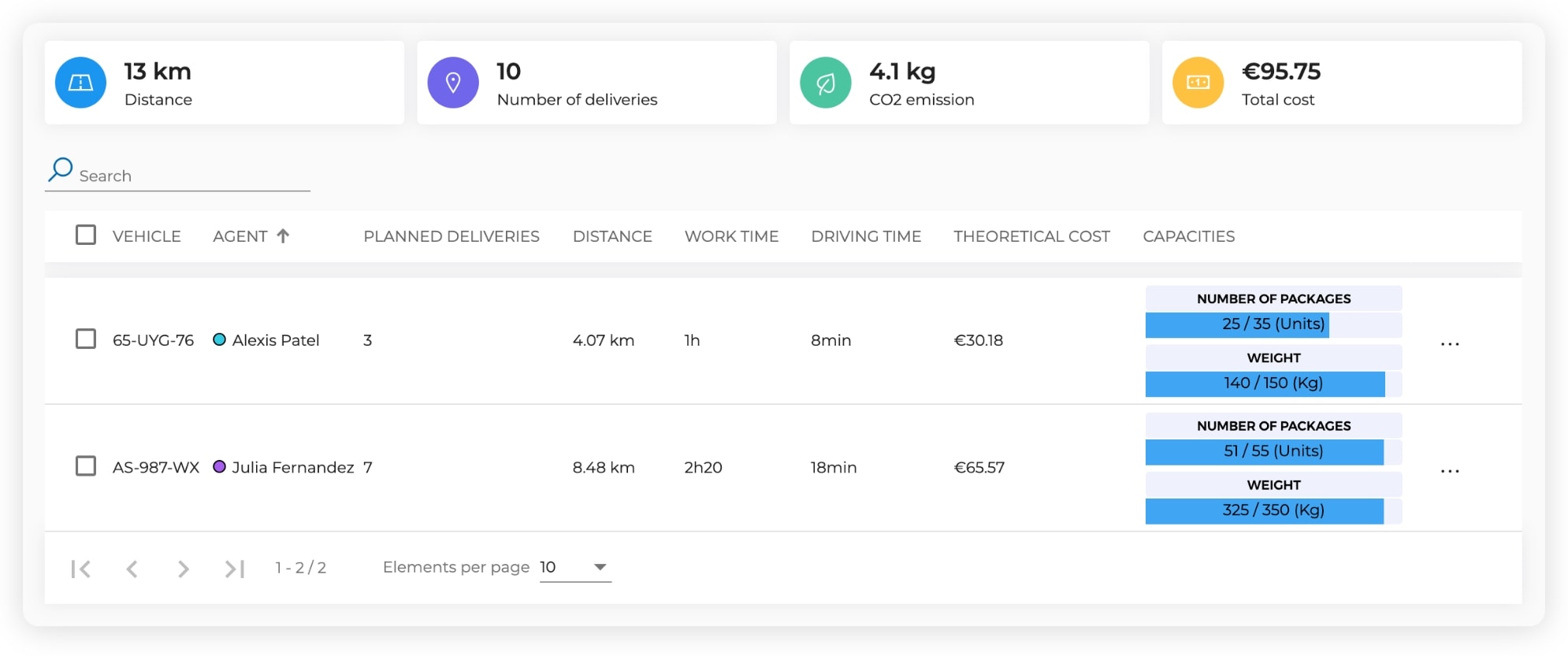

The optimisation of vehicle load rates on AntsRoute.

3. Automated route planning and dynamic delivery scheduling

To optimise your deliveries, the most important thing is to reduce the number of miles travelled. So it’s essential to optimise your delivery routes.

Among the many data related to deliveries are:

- delivery addresses,

- delivery times and customer preferences,

- drivers’ working hours, breaks and days off,

- vehicle capacities.

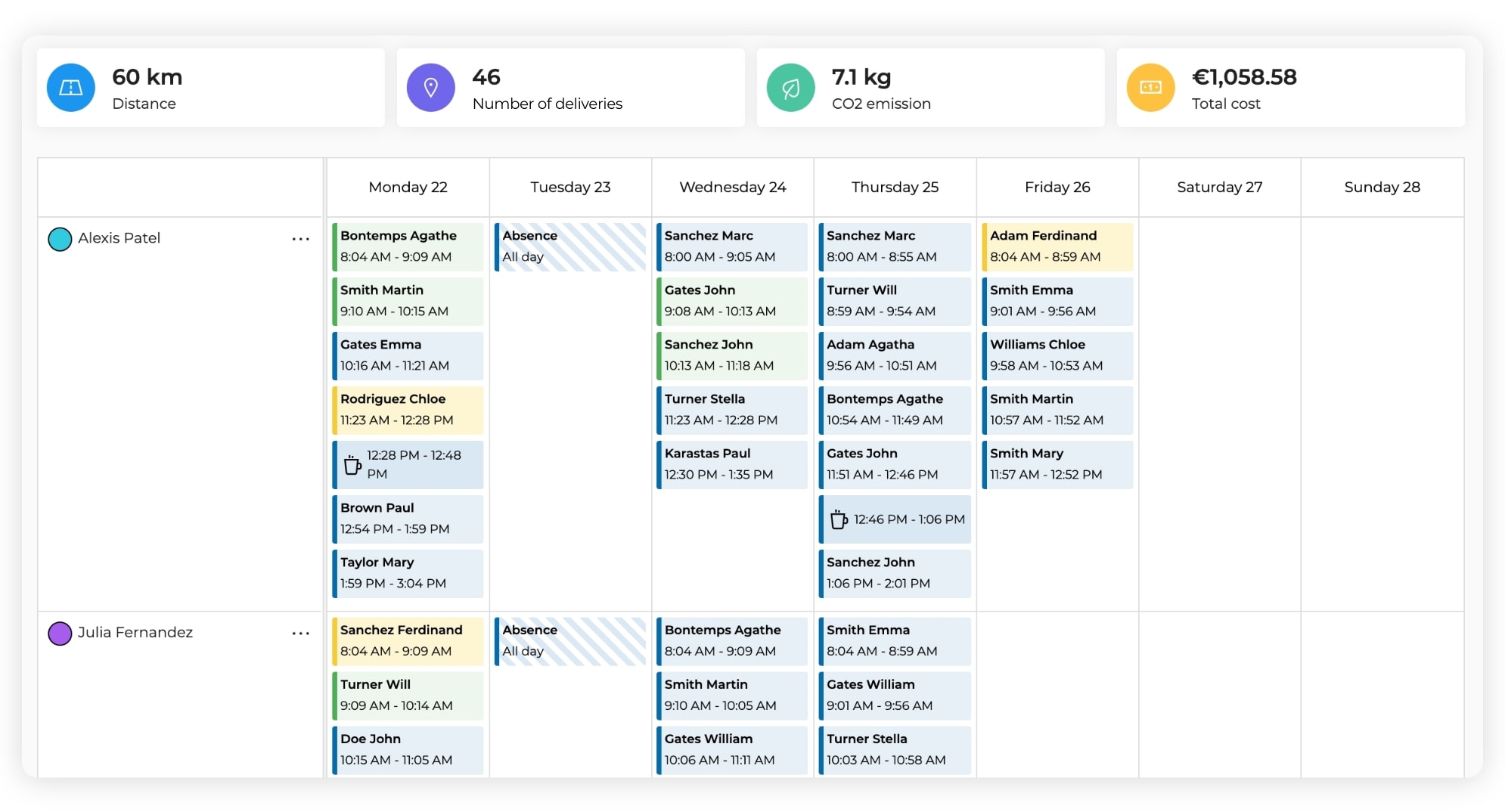

Imagine software that can organise all this data, so that with just a few clicks you can create route planning and an optimised route sheet tailored to each driver.

That’s what route optimisation software offers.

They can also be linked to a navigation app, giving you real-time access to traffic conditions.

They can then:

- automatically recalculate your routes,

- and adjust your delivery routes accordingly.

It’s an invaluable tool for avoiding traffic jams, reducing delays, continuously optimising your routes and improving both your profitability and customer satisfaction.

4. Improved visibility throughout the delivery process

The GPS tracking systems included in route optimisation software also allow you to track your parcels in real time. You can identify the location of your vehicles and packages at any time. This means you can detect potential problems, such as delays or routing errors, and take corrective action quickly.

By setting up an automated notification system, your customers can also be kept informed of important details concerning the delivery of their goods:

- pick-up, sorting,

- arrival at a local delivery hub,

- ongoing delivery, etc.

This keeps them informed about the progress of their deliveries and enables them to be better prepared. This helps to increase the success rate of first-time deliveries.

Some applications go even further, giving customers the option of postponing the delivery date or re-routing the delivery to a drop-off point if they are absent. These are all “no shows” that can be avoided.

5. Monitoring the carbon footprint of deliveries

Reducing CO2 and fine-particle emissions is becoming essential for all transport companies. The aim is to help protect our planet and reduce health risks, as well as meeting new regulations and the growing demands of consumers and principals.

By identifying and tracking your sources of emissions, you can measure your carbon footprint at every key stage of your deliveries:

- sorting, packing, filling vehicles,

- transport between platforms,

- last-mile delivery, depending on the location and delivery method.

But it’s not always easy to make these calculations. Some route optimisation software can help, by indicating in your route plans the emission rate of different routes, depending on the delivery method and location chosen. This will enable you to select the least costly or least polluting route, which often go hand in hand.

AntsRoute displays the CO2 emissions in the route planning.

Example of AntsRoute route optimisation software

By now, you’re thinking that these optimisation algorithms and software solutions may be very interesting, but they must also be very expensive.

Well, there are some very affordable apps out there that offer feature packs tailored to your needs and the size of your business.

AntsRoute software, for example, is available from €24 per month per vehicle.

It won’t let you optimise packaging or automatically sort products in a distribution centre.

It does, however, give you access to many route optimisation functions:

- Automated planning of the most efficient delivery routes, based on distance, CO2 emissions, traffic, delivery times and customer preferences.

- Smart route planning for your drivers, based on delivery time slots, selected routes, vehicle capacity, working hours and customer priorities.

- Monitoring of the fill rate of your vehicles, based on vehicle type, load capacity and height.

- Automated updating of planning and route orders in the case of unforeseen events: order cancellations, postponed deliveries, blocked roads, wrong addresses, etc.

- Real-time tracking: precise vehicle location, route completion, delivery states, and automated customer notifications.

- Analysis of performance: detailed reports and analyses of delivery route performance (delivery times, miles travelled, use of resources).

By investing in dedicated software such as AntsRoute, you can benefit from the power of its optimisation algorithms. All you have to do is enter your constraints and objectives into an Excel spreadsheet or Google Sheet. And that’s it!

If you’re interested in this software, a free trial is available on request.

Free 7-day trial | No credit card required

Contenu

- How can you optimise your parcel and goods deliveries?

- The 5 benefits of software to optimise the delivery of your goods

- 1. Automated sorting and sequencing of orders

- 2. The optimisation of vehicle loading

- 3. Automated route planning and dynamic delivery scheduling

- 4. Improved visibility throughout the delivery process

- 5. Monitoring the carbon footprint of deliveries

- Example of AntsRoute route optimisation software