Customer Satisfaction and Cost Reduction: Why Reverse Logistics Is Essential for your Business

Reverse logistics, often overlooked, is in fact a strategic lever for optimising your supply chain, building customer loyalty and enhancing your commitment to Corporate Social Responsibility (CSR). Properly implemented, it benefits everyone: from the online merchant to the warehouse manager, right through to the end customer. Better still, it’s a real opportunity for your company to stand out from the competition! We’ll explain!

Table of contents:

- What Is Reverse Logistics?

- The Economic and Strategic Advantages of Reverse Logistics

- The Sectors Most Concerned by Reverse Logistics

- The Positive Impact of Reverse Logistics on Customer Satisfaction

- Reverse Logistics and Sustainability: Towards a Circular Economy

- The Main Challenges of Reverse Logistics

- How to Integrate Reverse Logistics with AntsRoute

The Reverse Logistics is an essential process in the supply chain. Optimising it improves customer satisfaction and reduces logistics costs. The companies can strengthen their brand image by demonstrating their commitment to CSR.

What Is Reverse Logistics?

Reverse logistics comprises all the processes associated with returning products to the manufacturer, including reuse, recycling, reconditioning or disposal in a responsible manner. It includes steps such as collecting, transporting, sorting, repairing and tracking returned products.

In sectors such as e-commerce, electronics and fashion, where returns are frequent, reverse logistics helps optimise flows and add value to each product.

The Economic and Strategic Advantages of Reverse Logistics

Reverse logistics can bring significant benefits to your business on several levels, including cost reduction, resource optimisation and customer satisfaction.

Reducing costs and optimising resources

Reverse logistics enables companies to turn returns into real business opportunities:

- Reduced disposal costs: By collecting defective or unsold products, companies reduce waste management costs.

- Value recovery: By reconditioning, recycling or reselling returned products, part of their value can be recovered. This reduces waste and generates additional income.

- Optimised stock management: By integrating returns into their stock management strategy, companies can better control their inventory, reduce storage costs and avoid product obsolescence.

Increasing sales and customer loyalty

A transparent and simple returns process has a direct impact on purchasing decisions:

- Ease of returns: A hassle-free returns process boosts customer confidence and encourages them to come back.

- After-sales problem management: Prompt handling of returns for faulty products or dissatisfaction demonstrates attention to customer needs.

- Warranty policies: Effective management of warranties and repairs reinforces confidence in the brand.

A competitive advantage

Managing reverse logistics enables you to stand out from the competition through greater operational efficiency and improved customer satisfaction.

Amazon, for example, manages around 250,000 returns a year through its partnership with ReturnGo, illustrating the strategic impact of reverse logistics in optimising large volumes of returns.

Reverse logistics can bring significant benefits to your business.

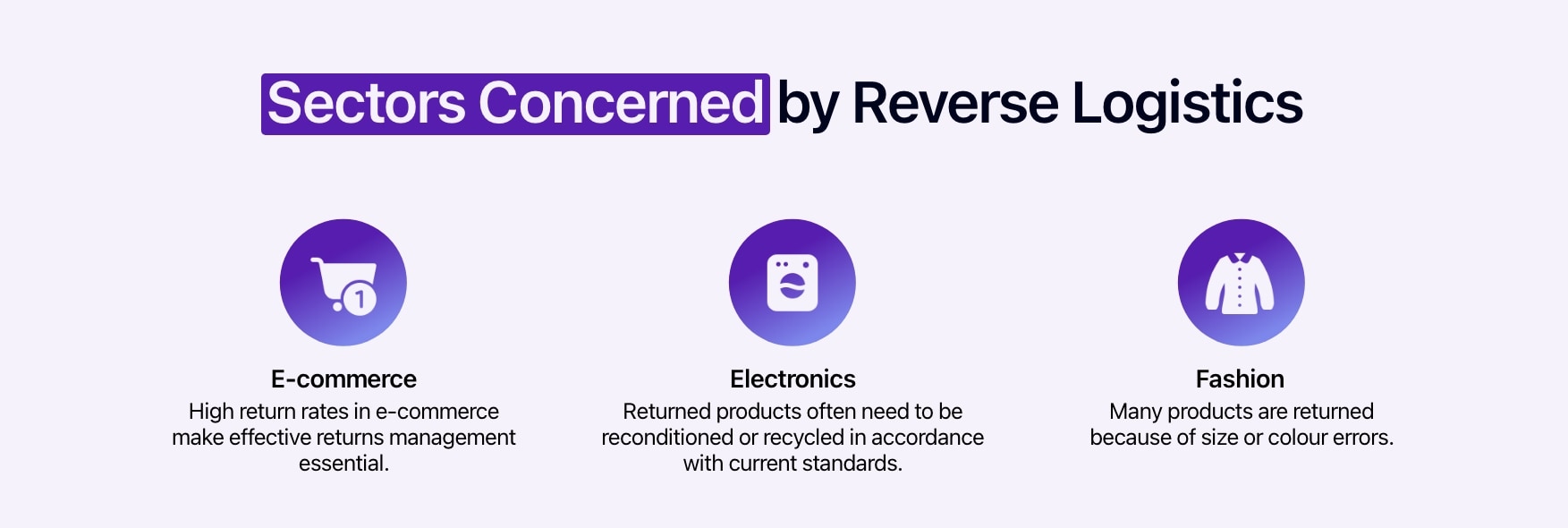

The Sectors Most Concerned by Reverse Logistics

Reverse logistics is particularly important in certain sectors where product returns are frequent, such as:

- E-commerce: High return rates in e-commerce make effective returns management essential. The convenience of this process is a key criterion for retaining online customers.

- Electronics: Returned products often need to be reconditioned or recycled in accordance with current standards, due to the toxic components or complexity of the equipment.

- Fashion: Many products are returned because of size or colour errors. Smooth returns management helps brands minimise processing costs.

The sectors most concerned by reverse logistics.

The Positive Impact of Reverse Logistics on Customer Satisfaction

Reverse logistics is a major asset for improving the customer experience by simplifying returns. Leading retailers such as Amazon understand this and use automated processes to instantly generate return labels and offer flexible delivery options, such as nearby collection points. This system facilitates the returns procedure, reinforces brand confidence and encourages customer loyalty.

Amazon’s example shows how well thought-out reverse logistics can transform the customer experience. Here are the main benefits:

- Simple returns: By reducing the effort required to return a product, it makes life easier for buyers and meets their expectations of convenience.

- Flexible return options: Fast solutions tailored to customer preferences increase brand confidence.

- Optimised after-sales service: A smooth returns process improves the brand’s image, enhancing its value in the eyes of consumers.

- Reduced resolution time: By minimising the wait for returns to be resolved, it makes customers feel that they are being heard and taken into account.

- Encouraging repeat purchases: A reassuring returns policy encourages customers to come back and buy again.

ASOS’s proactive policy, for example, allows free returns over a long period of time, reassuring shoppers and stimulating impulse or repeat purchases. According to “Pulse of Online Shopper” study conducted by UPS, 56% of online shoppers check the returns policy before finalising their purchase, underlining the importance of well thought-out reverse logistics in attracting and retaining customers.

The 5 main benefits of reverse logistics on customer satisfaction.

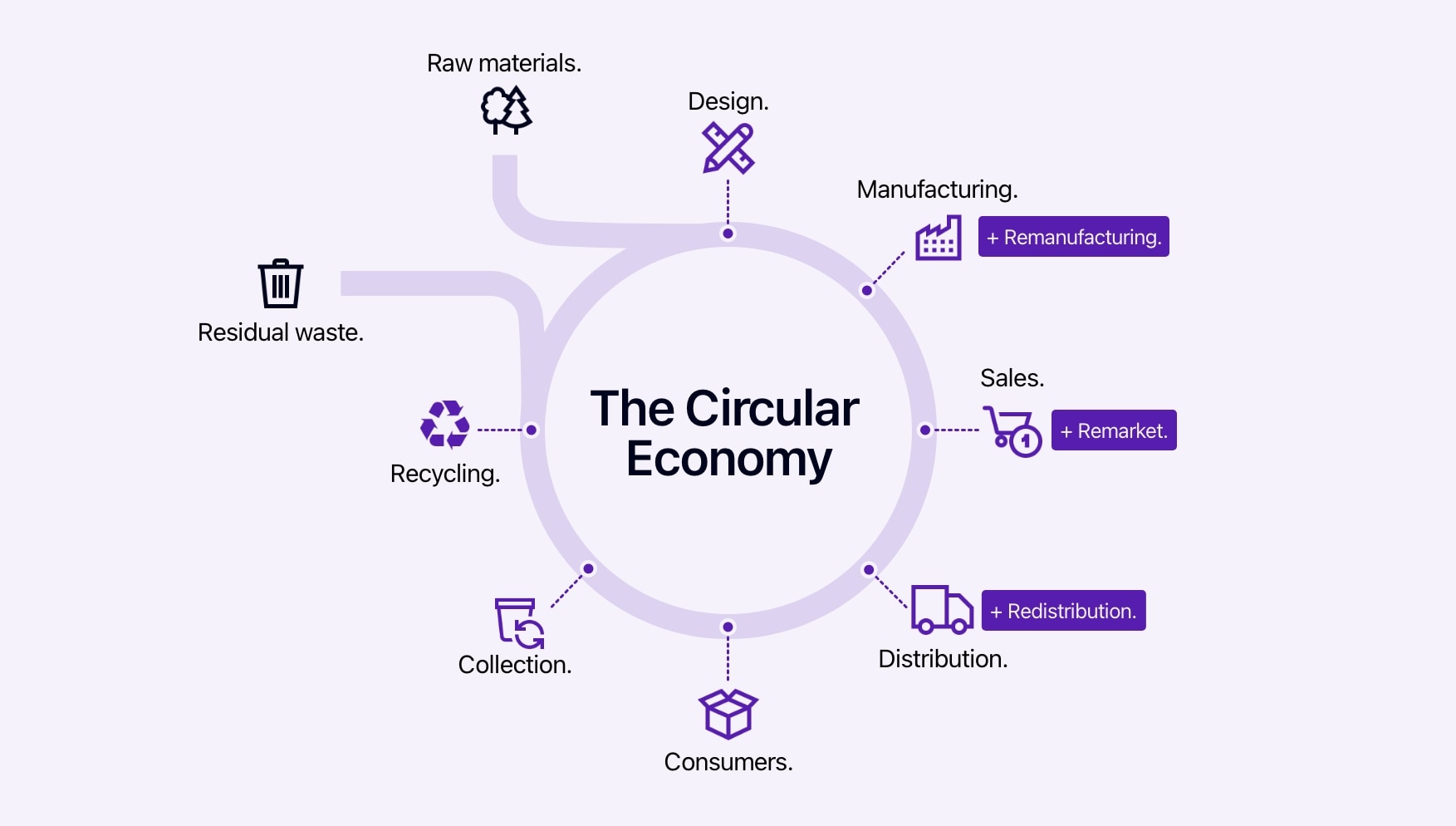

Reverse Logistics and Sustainability: Towards a Circular Economy

Reverse logistics fits perfectly with sustainable development and circular economy initiatives. It enables companies to reduce their ecological footprint by limiting waste and encouraging the reuse of products.

- Recycling and waste management: By handling returns correctly, companies can reduce their environmental impact, particularly in sectors such as construction and public works, where excess debris and materials need to be managed strictly and in line with standards.

- Saving raw materials: By favouring the re-use of products, companies reduce their dependence on new resources, enabling them to comply with increasingly strict waste management regulations.

Regulations such as Extended Producer Responsibility (EPR) are also encouraging companies to adopt reverse logistics practices. By complying with these requirements, they can avoid costly fines while boosting their image with consumers, who are increasingly sensitive to brands’ ecological commitments.

Logistics is part of circular economy initiatives.

The Main Challenges of Reverse Logistics

Implementing efficient reverse logistics can be complex. Here are the main challenges facing companies:

- Fluctuating volumes: Product returns are often irregular and unpredictable, making it difficult to plan the resources needed to manage these flows.

- Condition of returned items: Each returned product must be meticulously checked to ensure that it is compliant and in good condition – an often laborious task. Fortunately, automation and artificial intelligence can simplify this stage.

- High processing costs: Managing returns involves numerous stages – reception, inspection, sorting, repackaging, recycling – which increase the unit cost of each returned product. However, good organisation and the right tools can considerably reduce these costs.

- Stock management: The unpredictable nature of returns complicates stock balancing. But by integrating real-time management solutions, it is possible to improve the accuracy of inventories and avoid stock-outs or surpluses.

Solutions such as those offered by Doddle and Blue Yonder make it possible to integrate returns management into the overall supply chain, optimising the entire process.

Implementing efficient reverse logistics can be a complex task.

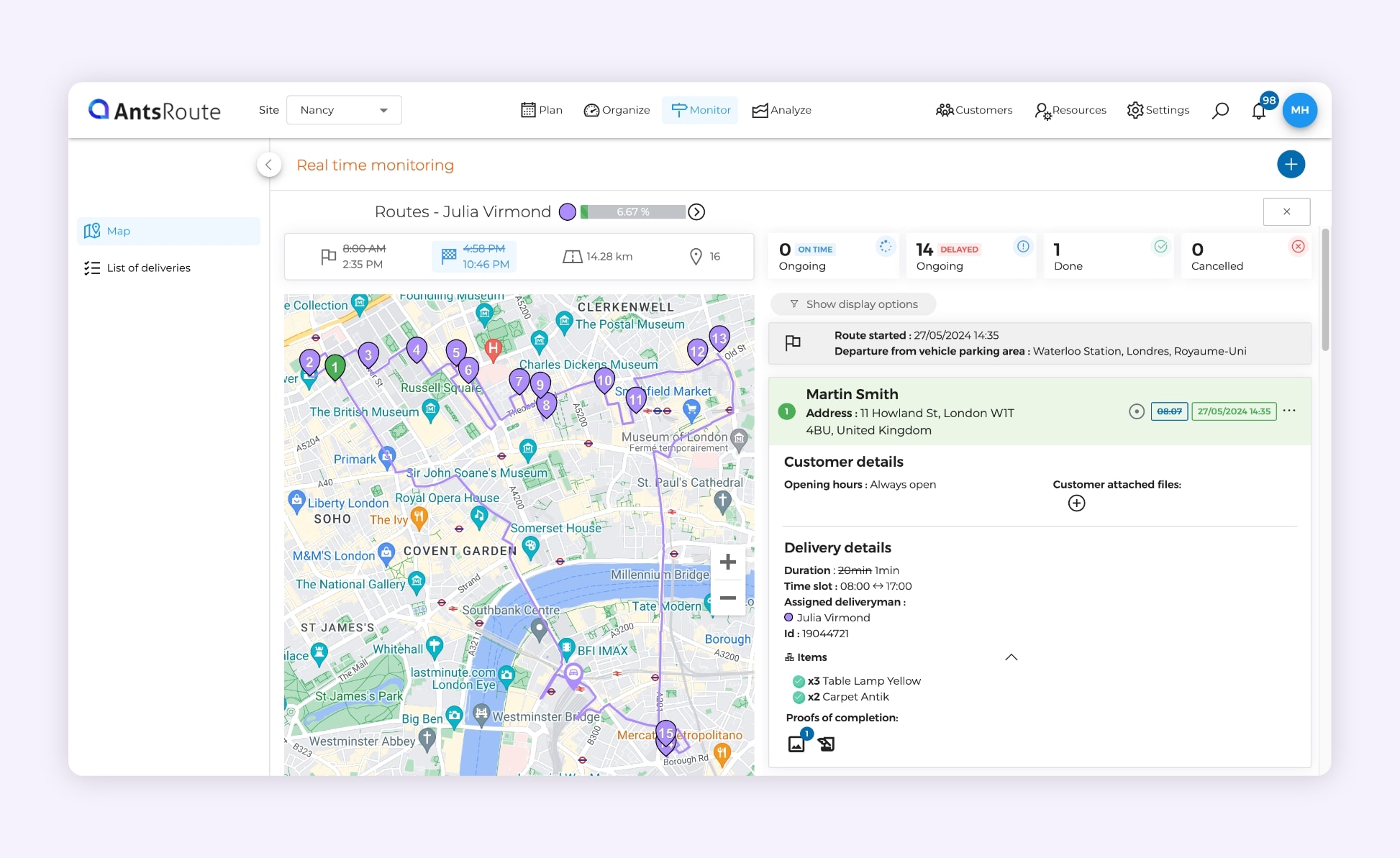

How to Integrate Reverse Logistics with AntsRoute

Managing returns efficiently is a real challenge, but with the integration of a Warehouse Management System (WMS) combined with AntsRoute, your reverse logistics becomes a strategic asset. Thanks to our route planning and optimisation software, you can easily organise the collection or return of products directly from your customers, in a process that’s as smooth as delivery.

AntsRoute route optimisation software.

Find out more about the benefits of this integration:

- Total product traceability: Track every return transparently and ensure optimum management, while complying with ecological standards.

- Intelligent automation: Artificial intelligence, big data and blockchain automate the sorting and classification of returns. Depending on their condition, type and reason, the process is automatically triggered: exchange, restocking, repair or recycling. This reduces errors and increases the profitability of each return.

- Real-time stock management: As soon as returned products are received, they are inspected and repackaged so that they can be put back on sale quickly, reducing downtime and maximising the value of each returned product.

- Reduced human error: Automating reverse logistics processes reduces the risk of operational errors and improves efficiency.

- Reconditioning and responsible recycling: The WMS directs each returned product to the appropriate centre for environmentally responsible processing.

- Detailed reporting and analysis: Access detailed reports to better understand your returns trends, spot quality problems and identify areas for improvement.

Test AntsRoute for free for 7 days to optimise your returns and boost your competitiveness!

WRITTEN BY

Florine Martin

Florine has been a freelance web copywriter since 2021, writing for a variety of clients in a range of sectors. Since the beginning of 2024, she has been writing articles about logistics for our company, AntsRoute.

Free 7-day trial | No credit card required

Contenu

- What Is Reverse Logistics?

- The Economic and Strategic Advantages of Reverse Logistics

- Reducing costs and optimising resources

- Increasing sales and customer loyalty

- A competitive advantage

- The Sectors Most Concerned by Reverse Logistics

- The Positive Impact of Reverse Logistics on Customer Satisfaction

- Reverse Logistics and Sustainability: Towards a Circular Economy

- The Main Challenges of Reverse Logistics

- How to Integrate Reverse Logistics with AntsRoute