Automate the management of maintenance contracts to optimise your costs in the field

Blog > Field Service > Automate the management of maintenance contracts to optimise your costs in the field

Automate the management of maintenance contracts to optimise your costs in the field

Published on 13 December 2023 • Reading time: 6 min read

Maintenance contracts are a guarantee of peace of mind for both customers and service providers. In many business areas, they are even considered as essential: industrial maintenance, vehicle maintenance, IT, lifts, fire safety, etc.

For the company offering these services, this formula is perfect for smoothing out invoicing, but it does require careful management, at the risk of seeing profitability plummet.

What do you need to know to improve the management of these contracts and protect your margins?

Table of contents

- The maintenance contract: an attractive option for all stakeholders

- What type of software should you choose to manage field services and optimise your operating costs?

- The essential features for managing your maintenance contracts

- Plan all the field services to be carried out

- Improve management of materials and spare parts

- Facilitate communication between all stakeholders

- Monitor the work of field technicians in real time

- Automate the writing of service reports

- Track the execution of contracts using relevant key performance indicators

The automated management of maintenance contracts is essential for optimising costs. CMMS and route optimisation software offer greater profitability. For maintenance companies, automation is a lever for growth.

The maintenance contract: an attractive option for all stakeholders

The benefits of a maintenance contract for the customer

The outsourcing of maintenance through such a contract gives customers complete transparency over their expenses. The contract also guarantees a regular maintenance by service providers who have received specific training for this type of equipment. Depending on the package chosen, the contract may include:

- Tests or inspections to prevent breakdowns.

- Application of treatments or protective products.

- Inspection of equipment or safety systems.

- Repair or replacement of equipment in the event of a breakdown, etc.

The objective of this periodic maintenance is, of course, to avoid any breakdowns and extend the life of the equipment.

The essential clauses of these contracts

The maintenance contract usually includes:

- The names and contact details of the parties involved.

- The references of the equipment concerned.

- The site(s) where the work will be carried out.

- The services included in the chosen package: functional tests, commissioning advice, first-level maintenance, visual inspection, full after-sales service, etc.

- The frequency. Does the technician visit every quarter? Once during the heating season? Only at the customer’s request, etc.

- The timescale, or even a guaranteed fault repair time.

- The customer’s obligations.

- Price and payment terms.

- Exclusions from the guarantee.

- The duration of the contract, its expiry date and renewal conditions.

- Details of dispute resolution, such as the competent court, etc.

Some maintenance software packages provide templates of compulsory and optional clauses, which can be adapted to your business area. To effectively prevent disputes and unpaid bills, however, it’s better to have them drafted by a lawyer!

What type of software should you choose to manage field services and optimise your operating costs?

While maintenance contracts guarantee you regular income, the profitability of this type of service needs to be closely monitored. For example, for a supplier of industrial equipment, all it takes is a series of recurring breakdowns on a specific model for the margin level to plummet.

That’s why, as well as drawing up contracts, it’s better to have a reliable IT tool to monitor your operational commitments over time.

In other words, you’ll need to rely on one or more software packages to plan maintenance operations and optimise the work of your teams in the field.

The right software simplifies work scheduling and optimises operating costs.

CMMS software

Some tools are computerized maintenance management system (CMMS) software. Their aim is to make maintenance operations easier, thanks to a range of functions such as:

- A document database with instructions for use, technical specifications, etc.

- Creation and monitoring of preventive and corrective maintenance schedules.

- Detailed history of field services on a site or at a customer’s premises.

- Management of consumables and spare parts stock.

- Dispatch and tracking of replenishment orders.

CMMS software is primarily aimed at companies that manage a large in-house stock of spare parts. It may also be suitable if you only work on a limited number of sites.

Route optimisation software

These tools offer many services for optimum management of field service operations… and much more besides.

With our software, for example, it only takes a few minutes to organise complex work order routes, taking multiple parameters into account:

- Availability time slots of customers.

- Maximum deadline or recurrence of field services.

- Technical skills, types of licences and authorisations.

- Occupancy rate of each technician.

- Pick-up and delivery routes, including trips to the warehouse to pick up equipment or spare parts, etc.

Depending on the technical level of your business, you can use route management software on its own or in connection with CMMS software. If so, make sure that there is an interconnection system between your different tools so that they can exchange information easily.

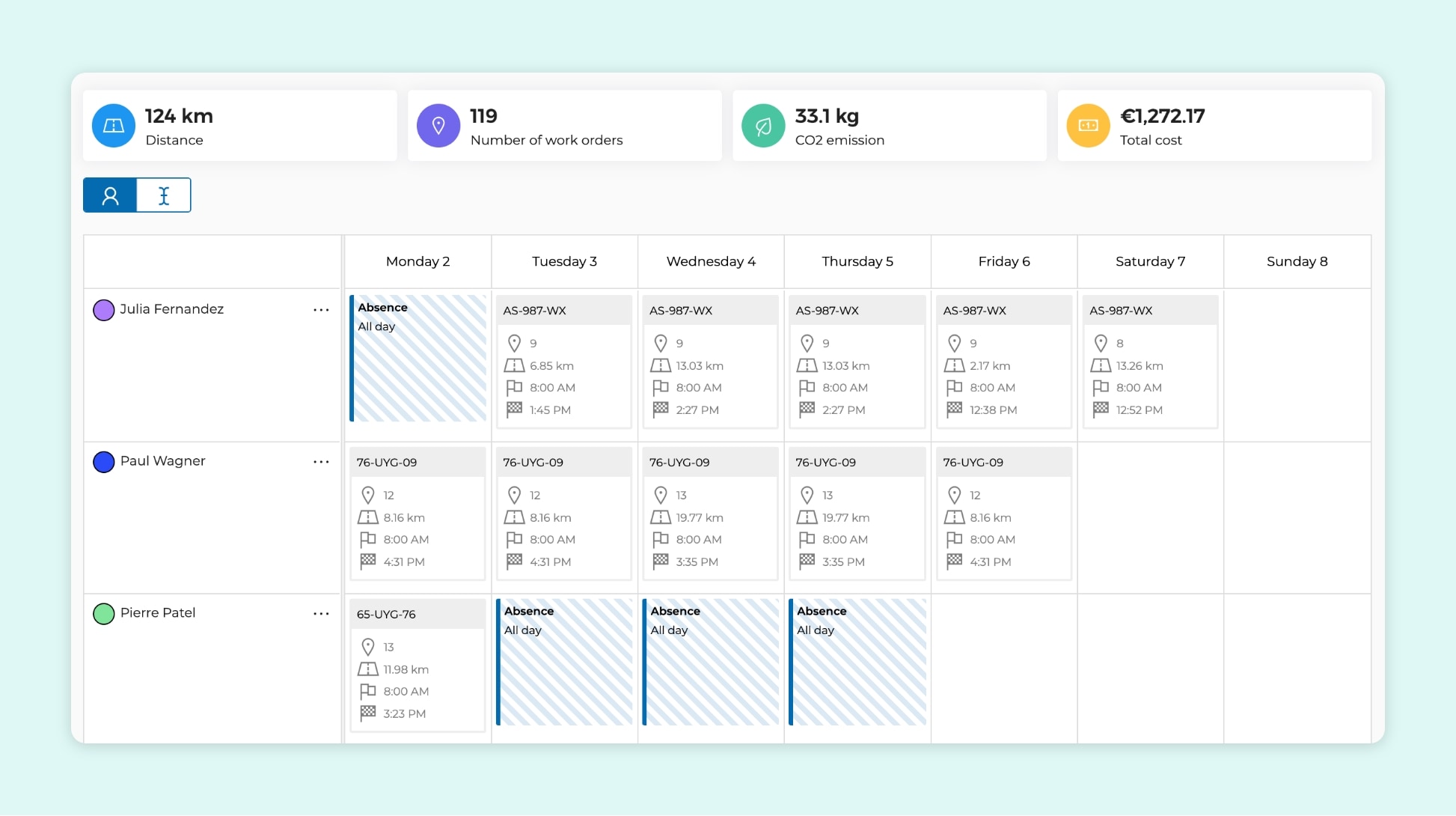

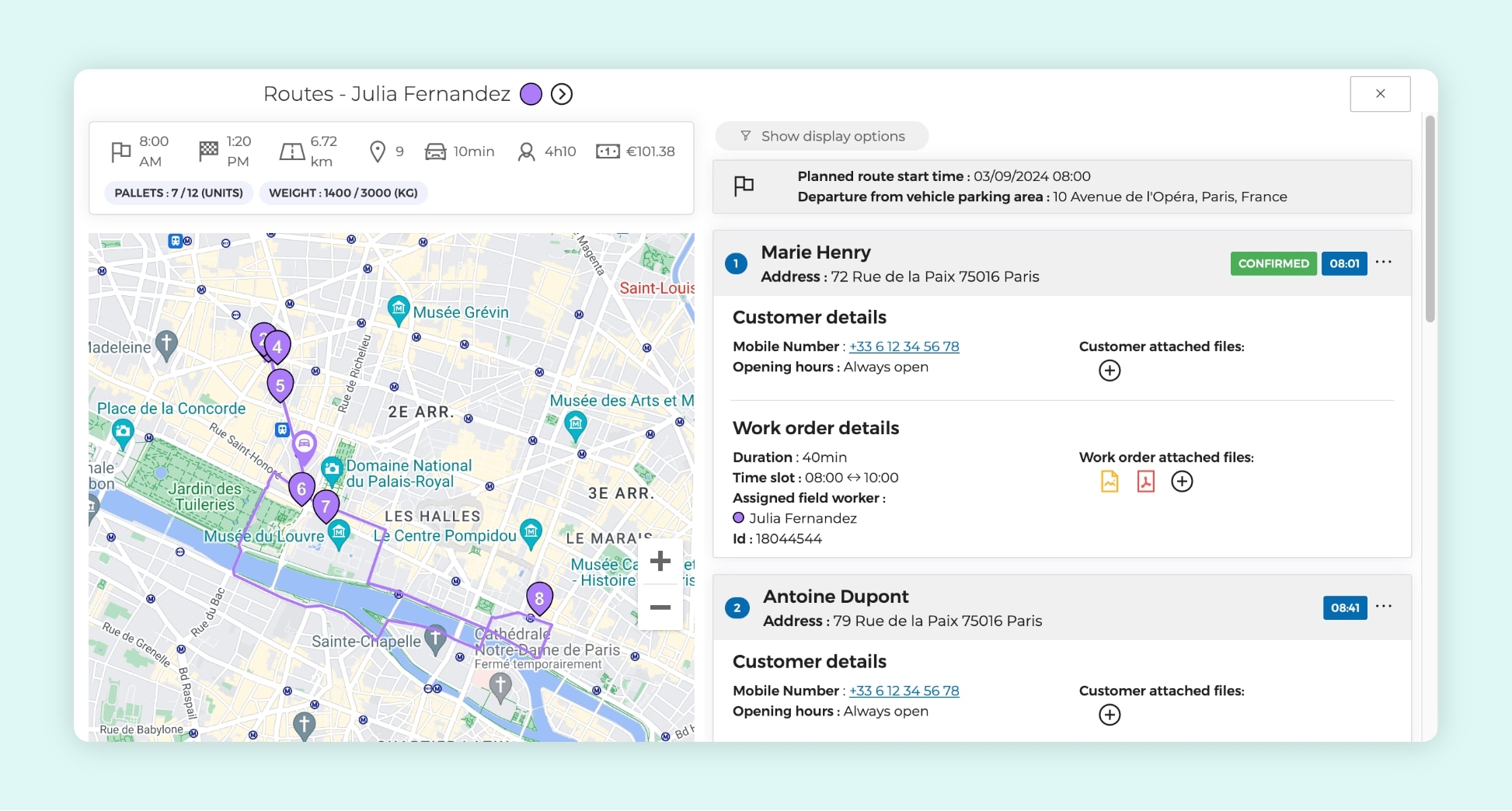

The list of technicians’ weekly routes on AntsRoute.

The essential features for managing your maintenance contracts

Plan all the field services to be carried out

Does that sound obvious? In fact, some software packages offer nothing more than an enhanced spreadsheet, while others such as AntsRoute offer highly advanced work order planning and dispatching functions.

In addition to geographical optimisation of routes, our tool manages multiple methods of making appointments: on incoming calls, from your website, using information transmitted by other software, etc.

Your technicians can also create or reschedule jobs directly from the mobile application.

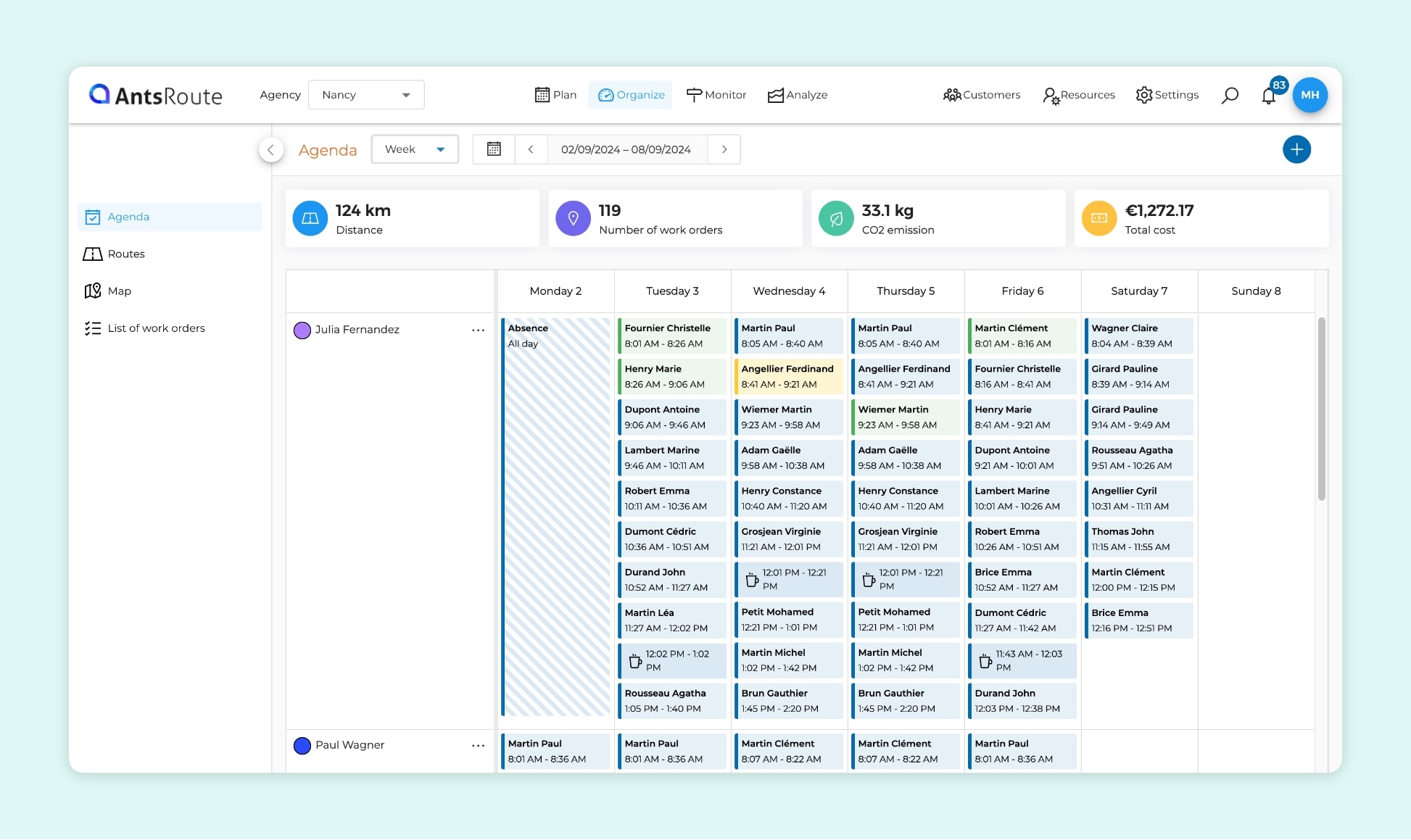

The weekly schedule of field technicians on AntsRoute.

Improve management of materials and spare parts

Each technician must be able to check the list of equipment or tools to be taken on board before each job.

If the equipment or supplies are stored in several geographically distant warehouses, your service management software must absolutely take this constraint into account when creating the schedule!

Facilitate communication between all stakeholders

To optimise the work of technicians in the field, they need to be able to view and exchange as much information as possible with customers and the maintenance manager, in complete autonomy.

A number of features can help you achieve this goal:

- Sending notifications to customers by e-mail or SMS.

- History with details of past field services.

- Detailed description of the service to be carried out.

- Updating of the customer file by the technician himself, etc.

Monitor the work of field technicians in real time

An unusual traffic jam or an accident on the road? A vehicle that breaks down or a repair that takes too long?

Certain functions make it much easier to manage teams in real time:

- Automated notification to the customer in the event of delays.

- Analysis of different options in terms of time and kilometres.

- Real-time updating of team schedules, etc.

Tracking of field workers in real time on AntsRoute.

Automate the writing of service reports

It is in your interest to automate the writing of visit reports, which is considered a real burden by most technicians:

- Photos to prove the conformity of the installation or repair.

- Electronic signature.

- Customised fields with conditions to simplify the drafting process as much as possible: date and time of visit, tick boxes, list of parts used, comments, price, additional services, etc.

It’s a practical, effective solution for ensuring that work is carried out in accordance with the maintenance contract and preventing disputes!

Track the execution of contracts using relevant key performance indicators

Certain key performance indicators (KPIs) are essential for monitoring your margins and making the necessary adjustments quickly. In particular, our tool provides you with key figures about:

- The rate of on-time service, i.e. service completed on time.

- Time spent at the customer’s premises compared with total working time.

- Average costs per route, per operation, per vehicle, etc.

Do you want to test our software free of charge to improve the management of maintenance contracts in the field? Go to this page!

Free 7-day trial | No credit card required

Contenu

- The maintenance contract: an attractive option for all stakeholders

- The benefits of a maintenance contract for the customer

- The essential clauses of these contracts

- What type of software should you choose to manage field services and optimise your operating costs?

- CMMS software

- Route optimisation software

- The essential features for managing your maintenance contracts

- Plan all the field services to be carried out

- Improve management of materials and spare parts

- Facilitate communication between all stakeholders

- Monitor the work of field technicians in real time

- Automate the writing of service reports

- Track the execution of contracts using relevant key performance indicators