The best strategies for optimising your supply chain

The supply chain linking factories producing raw materials to end customers is becoming longer and longer, but also increasingly unstable, as we have been brutally reminded by the pandemic crisis and the war in Ukraine.

To improve the visibility of your supply chain and make the best decisions in real time, you will need to analyse and optimise many parameters: relations with suppliers and service providers, supply chain management software, costs and delivery times, etc.

Far from being a simple modelling exercise, it involves implementing management tools and a long-term strategy to improve logistics processes, and therefore your company’s performance.

Table of contents

- What is the supply chain?

- Defining your strategic objectives: an essential step

- 7 effective methods for improving supply chain management

- Mapping information flows

- Optimising the flow of data using appropriate technologies

- Evaluating other useful technologies to improve your performance

- Automating or outsourcing low value-added operations

- Better training your employees in their core skills

- Analysing the causes of gaps and malfunctions

- Encouraging real-time decision-making

Optimising the supply chain is at the heart of today’s logistics challenges. For the operations manager, it’s a guarantee of better flow management and resistance to the unforeseen events of the market.

What is the supply chain?

The supply chain refers to all the players and flows that enable goods to be delivered to an end customer.

The links that make up this supply chain usually include :

- Manufacturing plants: suppliers of raw materials, processing plants, etc.

- Stocks of goods that will be transported from one company to another by logistics service providers.

- Storage locations: warehouses, cross-docking platforms on the outskirts of towns, drop-off locations, etc.

- Data flows: dates, quantities, references, order status, etc.

- Financial flows.

Defining your strategic objectives: an essential step

However, this definition of the supply chain remains highly theoretical and needs to be adapted to each individual company.

The processes for modelling and optimising the supply chain will obviously be very different for a traditional drinks producer and a global group like Coca-Cola.

What matters above all is to determine concrete, measurable objectives to make your business more competitive and profitable. Depending on your strategy and business model, you may want to focus on:

- Reduce the number of days that products are out of stock.

- Optimise the cost or time taken to transport goods.

- Improve the delivery rate on first visit, etc.

The supply chain is adapted to each company.

7 effective methods for improving supply chain management

Mapping information flows

The first problem affecting supply chain efficiency is often the fragmentation of information. The various data flows are aggregated in “silos”, which do not communicate with each other.

This immediately brings to mind the communication difficulties encountered by companies linked together within the supply chain. For example, a manufacturing plant and its suppliers, or a logistics service provider and its principals.

But this problem also very often arises within the same company because of an obsolete information system, or quite simply, departments that do not connect their data: the purchasing department and manufacturing, manufacturing and the transport department, and so on.

To optimise the exchange of information within the supply chain, you will need to map:

- Useful data.

- The departments or companies that have this data.

- The tools used to store this data: Excel spreadsheets, enterprise resource planning (ERP), warehouse management software (WMS), Transport Management System (TMS), etc.

Optimising the flow of data using appropriate technologies

Once you have identified the various IT tools through which relevant information is exchanged, the next step is to optimise their use, and therefore their cost.

Are they all really useful? Are they still the benchmark for your market? Would competing solutions be more effective in improving or measuring your key performance indicators (KPIs)? Is it in your company’s interest to combine several tools, or is it better to adopt a one single platform?

In recent years, the development of SaaS software, hosted in the cloud, has revolutionised the market.

These tools, in which the publisher takes charge of data storage and updates, have helped to accelerate the digital transition of many businesses, particularly smaller ones.

Another advantage of SaaS software is that most publishers have developed “gateways” to enable them to automatically exchange useful data, and thus connect information flows. There are several ways of doing this:

- Tailor-made integration for a given software package

- API

- No-code tools such as Zapier

- Alternatively, export in the form of an Excel spreadsheet.

The other good news is that, in most cases, the implementation of these connectors is already included in your subscription, or only requires a switch to a higher price plan.

Evaluating other useful technologies to improve your performance

Depending on your business, other innovative technologies can help you optimise your supply chain, such as:

- The artificial intelligence to improve purchasing planning, stock management, supplier monitoring, etc.

- The Internet of Things (IoT). This term refers to a whole range of connected objects such as RFID tags or intelligent sensors, capable of transmitting information in real time on stock levels, the temperature in a warehouse, the smooth running of a machine, and so on.

- The robotics, increasingly used in factories and distribution centres to speed up packaging operations, order preparation, etc.

Industry 4.0: Autonomous delivery by robots in a warehouse.

Automating or outsourcing low value-added operations

The objective of this method is obviously not to embark on uncontrolled purchases, which would be incompatible with the smooth management of your cash flow.

Instead, you need to identify the non-strategic, repetitive or low value-added tasks that you have an interest in:

- Either automate them.

- Or delegate them to service providers who have the efficient technology to carry out these operations at a lower cost.

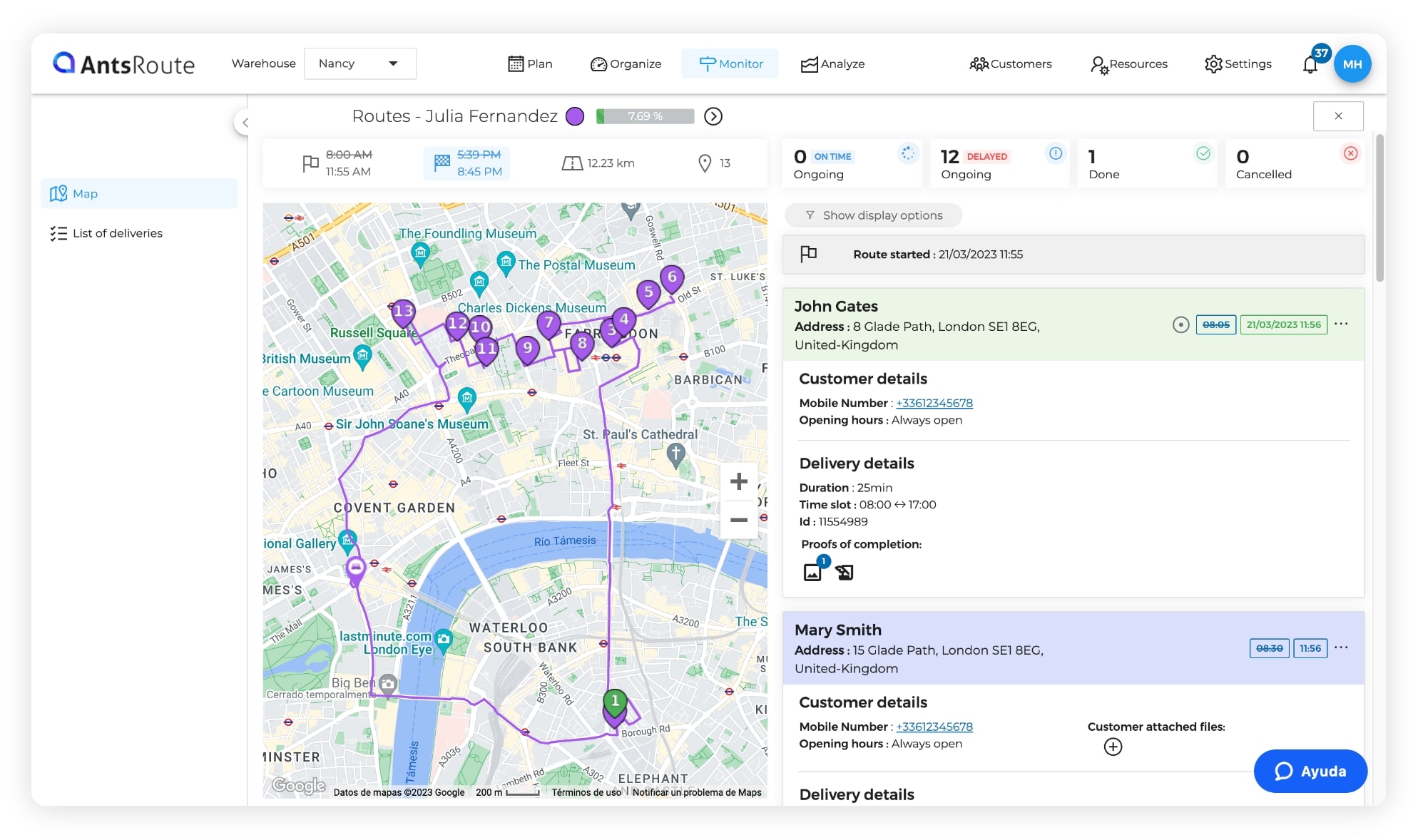

Let’s take the example of a process with which we are particularly familiar: the optimisation of delivery routes. Between planning routes, managing delivery notes, uncertain communication with customers and unforeseen events, some companies spend several hours a day on these operations!

But thanks to powerful algorithms capable of analysing massive data flows, good transport software is now far more efficient than human work, while eliminating oversights and data entry errors.

The AntsRoute route optimisation software.

Better training your employees in their core skills

Thanks to our software, most of our customers have saved several hours a day, which they have used to upgrade their skills and improve the quality of their services or products.

It’s the same for many time-consuming tasks, which literally consume the time of your teams: inventories, administrative management, repeated calls to drivers and partners, etc.

By gradually identifying solutions to delegate or automate these operations, you can free up time to allow your employees to focus on their core business, and so create more added value.

Analysing the causes of gaps and malfunctions

Are you seeing the first results of your actions? Keep in mind, however, that supply chain optimisation is an iterative process.

You’ll need to monitor the key performance indicators (KPIs) regularly to quickly identify anomalies and areas for improvement, and find solutions to improve efficiency.

This task of managing performance is made easier by the fact that today’s IT tools provide managers with a large amount of data and dashboards that are very easy to understand.

Encouraging real-time decision-making

This is one of the major lessons of the pandemic for management: the situation can change very quickly, due to events that still seemed unthinkable 3 months earlier.

On a global scale, supply chains are being really put to the test: health and climate crises, geopolitical conflicts, soaring raw material costs, driver shortages and so on.

To make the supply chain more efficient, but above all more resilient, companies need to implement processes to streamline decision-making and promote real-time response.

In concrete terms, for example, you can improve your sourcing and diversify your suppliers so that you can react quickly in the event of a stock alert.

If you manage field workers, you can also provide them with appropriate IT tools to:

- Redispatch tasks in the event of absence or traffic jam.

- Add an urgent delivery or field service operation in the ongoing route.

- Plan new appointments directly with customers when necessary, etc.

Do you want to test our delivery management software for free to optimise your routes and improve service quality? Just sign in here.

Free 7-day trial | No credit card required

Contenu

- What is the supply chain?

- Defining your strategic objectives: an essential step

- 7 effective methods for improving supply chain management

- Mapping information flows

- Optimising the flow of data using appropriate technologies

- Evaluating other useful technologies to improve your performance

- Automating or outsourcing low value-added operations

- Better training your employees in their core skills

- Analysing the causes of gaps and malfunctions

- Encouraging real-time decision-making