How to manage the collection of bio-waste? – the example of VALO’Prest

Blog > Route optimisation

How to manage the collection of bio-waste? – the example of VALO’Prest

Published on 19 February 2024 • Reading time: 7 min read

In a world with finite resources, the circular economy is becoming essential for extending the use of raw materials. VALO’Prest, our customer originally based in Moselle, France, and now operating throughout the Grand Est region, has already been experimenting this for several years with the collection, treatment and recovery of waste oils.

With the mandatory collection of bio-waste for all private households and businesses set to be extended from 01/01/2024 in France and from March 2026 in the UK, their methods could be an example for many businesses. So we talked to VALO’Prest’s Operations Manager, Alexis Laurent.

In this article, we share with you the results of his observations and our research about:

- VALO’Prest’s waste oil and biowaste collection system

- Future regulations and changes in bio-waste collection

- Methods for optimising the circular logistics of waste

The bio-waste collection is an essential part of the circular economy. Faced with new regulations and future changes, operations managers need to optimise the circular logistics of waste. There are solutions such as carbon-free processes, improved sorting at source and optimised routes.

Which system of waste collection and treatment has VALO’Prest implemented?

Let’s go back to the VALO’ Group‘s mission.

VALO’ is a group of around fifteen social economy companies. The group is made up of many different businesses, but they all share a core mission: insertion.

Several companies in the VALO’ Group specialise in the circular economy:

- VALO’Prest is in charge of waste collection, with a focus on re-use;

- Triplast, the recently created subsidiary, sorts end-of-life plastic and window frames so that they can be recycled more effectively;

- VALO’33 is a spin-off of the group in Gironde, which carries out similar tasks to VALO’Prest.

VALO’Prest is over 50% owned by its employees. From its Florange site in Moselle, it operates throughout the Lorraine region, and works in conjunction with VALO’33 in Gironde.

Collection of waste oils

Both sites use similar processes for collecting, sorting and recycling used oils.

They collect frying oils in blue 60, 120 or 220 litre drums, mainly from restaurants, and sometimes from school canteens or waste collection centres.

These oils are collected on request or on a regular basis (every fortnight or every month, depending on the contract).

The process is organised into 4 steps:

- The drivers carry out their routes on the same day or over 2 consecutive days. The oil collections are sometimes weekly.

- They take the drums of oil back to VALO’Prest’s sorting sites in Moselle or Gironde.

- They filter and store them. However, poor quality motor oils are simply discarded.

- The oil stored in IBC tanks at the 2 sites is pumped by tanker trucks and reinjected into the B100 biofuel circuit for heavy goods vehicles.

- At the Florange site, the oil is also transformed into a biodegradable biolubricant for chainsaws. This patented Biolub process requires additional filtration and the addition of natural additives to improve the product’s viscosity. It is then converted into small drums of 5 to 20 litres, depending on customer requirements.

Collection of bio-waste

VALO’Prest has also been collecting bio-waste for many years. This process has been stepped up since the beginning of the year, with the extension of source separation to all professionals.

Unlike oil, VALO’Prest collects bio-waste in wheeled bins, similar to dustbin containers. These bins are welded to the side to prevent leaks and odours during transport.

This bio-waste is then compressed into 660-litre pallet boxes, before being sent to a treatment centre for methanisation.

What are the forthcoming regulations and changes in bio-waste collection?

Obligation to sort and collect bio-waste at source

Bio-waste includes garden and park waste, as well as food and kitchen waste.

In France, source sorting of biowaste has been compulsory since 2016 for producers of more than 10 tonnes per year. This was also already the case for used oils, for any production of more than 60 litres per year.

From January 1, 2024, in accordance with the anti-waste law for a circular economy (AGEC), this obligation also applies to all producers and local authorities. The aim is to enable them to be recycled or returned to the soil, by composting in the facilities concerned, or by separate collection.

Development of EPR (Extended Producer Responsibility) policy and reorganisation of sectors

In France, the AGEC law also introduced 11 new EPR regulations, in addition to the 12 already established.

Mineral or synthetic oils, and construction materials (BMCP) have been included since January 1, 2022. Packaging for catering professionals was added in 2023, before the launch of EPR for all other packaging in 2025.

These sectors have been set up to deal with the end-of-life of products placed on the market, and to improve their re-use and traceability.

The producers involved in these schemes must choose an eco-organisation. The latter then issues calls for bids to collecting organisations. The aim is to nationalise and make the sector more professional, taking the circular economy to a new level.

The EPR is also changing the working process of collectors such as VALO’Prest:

- The collector no longer deals directly with customers. They are selected by an eco-organisation through a call for tenders.

- To win these tenders, the collector has to prove its ability to handle larger volumes. This is why the Triplast sorting unit has been set up, and why there are new cooperation projects with groups such as Suez.

The Extended Producer Responsibility schemes by Zero Waste Scotland — https://www.zerowastescotland.org.uk/

Methods for optimising bio-waste logistics

Gathering and reducing the carbon footprint of processes

The creation of these sectors also generates more comprehensive responses to the environmental challenges raised by waste collection and the development of the circular economy.

To facilitate recycling, bio-waste must be:

- unpacked to separate food waste from packaging;

- shredded or dried to reduce collection frequency and odour;

- compacted to take up less space before shipment and methanisation;

- transported in large quantities, without generating more pollution.

These challenges require additional investment from collectors or the pooling of complementary techniques between players in the sector.

VALO’Prest is currently reorganising to be able to receive and process more bio-waste:

- It plans to work with partners equipped with bio-decongestioners to place bio-waste in bulk and facilitate its methanisation.

- It is also planning to deploy small electric vehicles to transport waste without emitting carbon dioxide. These will be followed by investment in watertight tipper trucks to further gather the waste sent to treatment centres. Together with the Suez group, it has included these projects in its response to the call for tenders for carbon-free waste collection in the Lorraine region (from Nancy to Thionville).

And these investments are far from being in vain. Some of these investments could be replicated for commercial packaging when EPR is introduced in 2025.

Improving sorting at source to develop the circular economy

The quantity is certainly important, to be able to gather together and limit transport costs. But the quality of sorting is crucial to the development of the circular economy.

VALO’Prest has found this to be particularly true with waste oils. It is difficult to make use of these oils, as they often contain mixtures of frying oil and motor oil. This means recreating the entire chemical structure in order to use them, which is not economically viable.

VALO’Prest has also experienced this with other types of waste, such as building materials.

The better waste is isolated at source, the easier it is to treat and recycle.

To reduce this impact, waste producers and waste recycling centres can be charged for over-sorting. This solution alerts them to the importance of this sorting stage.

The development of the circular economy requires improved sorting at source.

Optimising routes for greater efficiency

To be viable, collection operations also need to be optimised. And this is even more necessary when volumes are growing and the number of collection points per route is increasing.

According to Alexis Laurent, for well-known routes of 4 tippers per day, you don’t necessarily need software to organise collections. But when the number of collection points increases, with different volumes, it becomes a much tougher task. This was particularly the case for their bulky goods collections, with around twenty different addresses per route and disparate volumes depending on the items to be collected (from bedside tables to mattresses).

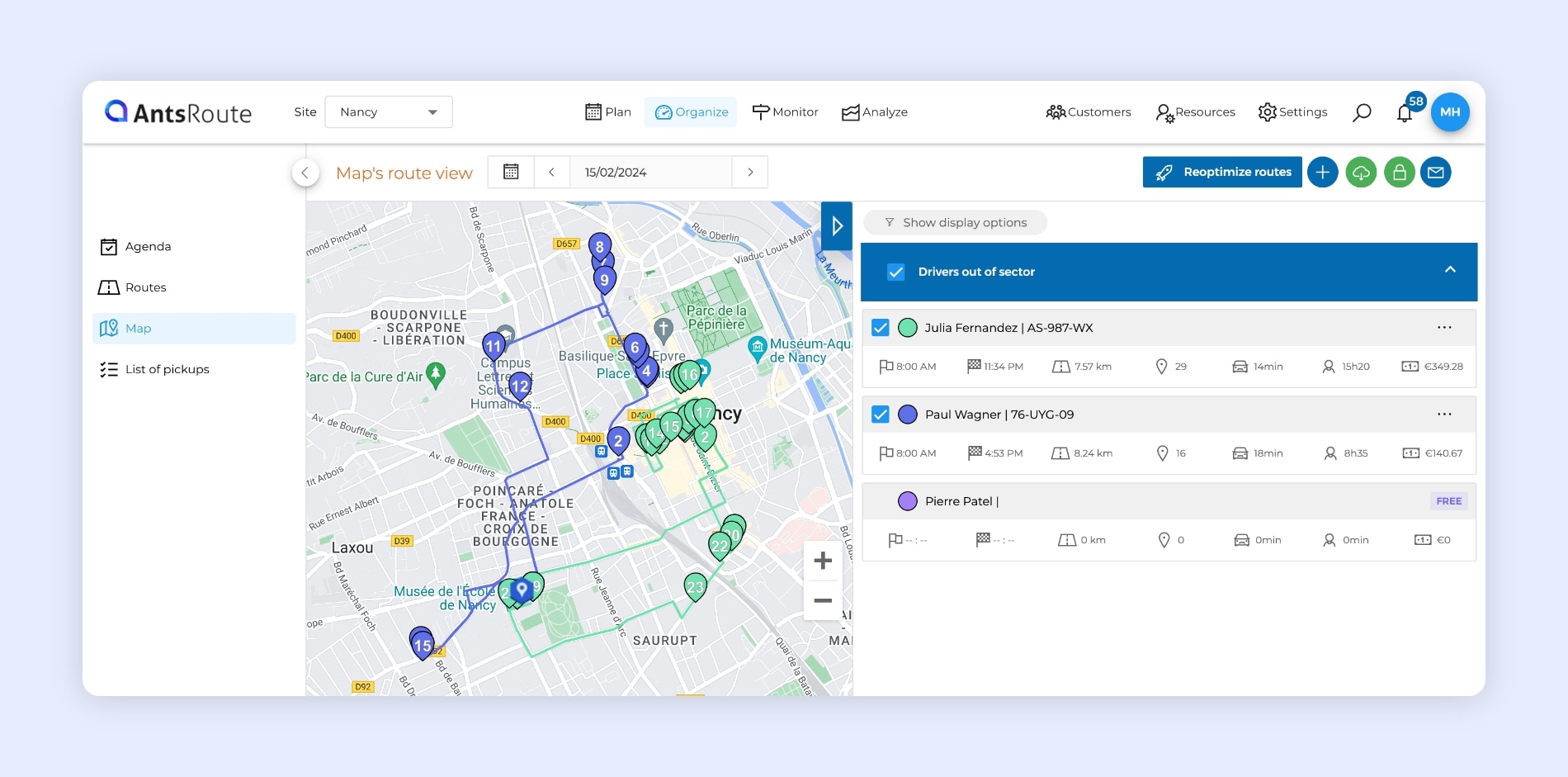

VALO’Prest chose AntsRoute route optimisation software 3 years ago. It enables the company to manage the routes of 3 drivers in Moselle and 7 drivers in Gironde.

In addition to bulky goods, VALO’Prest uses this software to collect cardboard from restaurants. And the company is starting to use it to collect waste oils.

In this way, it can better organise its routes and monitor the load rate of its vehicles. This is particularly useful in densely populated areas such as Bordeaux, or for dealing with other urban logistics issues.

But the route optimisation software is also very useful for deliveries of various materials or when collection points are located far from each other, as in Moselle.

The optimisation of waste collection routes on AntsRoute.

“And with the forthcoming contracts for bio-waste collection, the routes will be set up with AntsRoute, so the question doesn’t even arise. As with cardboard collection, with this software we no longer need to think about organising routes, and we save time, money and fuel”.

This software works in conjunction with their business software (stock, regulations, customer administration). And an API is currently being deployed to improve the flow between the 2 software packages. In particular, this will enable better management of the reporting obligations required by the REP.

The cooperation projects with AntsRoute also include the use of AI to optimise lorry packing.

The optimisation is becoming a major factor in this emerging bio-waste collection sector, to help it to be adopted quickly and effectively.

To test our route management software for 7 days, simply register here. The trial is free, with no commitment, and you don’t even need to enter your credit card number!

Free 7-day trial | No credit card required

Contenu

- Which system of waste collection and treatment has VALO’Prest implemented?

- Collection of waste oils

- Collection of bio-waste

- What are the forthcoming regulations and changes in bio-waste collection?

- Obligation to sort and collect bio-waste at source

- Development of EPR (Extended Producer Responsibility) policy and reorganisation of sectors

- Methods for optimising bio-waste logistics

- Gathering and reducing the carbon footprint of processes

- Improving sorting at source to develop the circular economy

- Optimising routes for greater efficiency