7 reliable ways to reduce your fleet’s fuel consumption

With an increase of more than 50% over the past 2 years, the price of diesel is severely compressing margins in the logistics sector. Most companies are passing on part of these increases by either embedding them in their invoices (the famous “fuel surcharge”) or by increasing the price of the products delivered.

Customers will not, however, be able to accept such frequent increases, especially not in the greater context of rampant inflation causing anxiety to consumers and transporters alike.

The only solution, therefore, remains to reduce the fuel consumption of your fleet by all means possible. For this, we’ve listed out 7 practical and legal methods that have proven themselves to be efficient.

Table of contents

- Train drivers in eco-driving

- Truly shut off the car engine when stopped

- Regularly run maintenance on the fleet of vehicles

- Optimise driving routes

- Use the right vehicle for the corresponding trip

- Increase the vehicle loading rate

- Deliver in staggered hours

Faced with rising costs, reducing fuel consumption is becoming a strategic issue for your corporate fleet. Optimising the use of the vehicle fleet helps to limit operating costs. It also reduces the environmental impact.

Train drivers in eco-driving

Contrary to popular belief, eco-driving does not consist of driving more slowly, nor extending transport times for the same journey. To consume less, the objective is rather to adopt flexible and smooth driving by taking advantage of some basic principles in mechanics.

According to the AA (Automobile Association), eco-driving can actually help drivers to save money. The association led a trial, which involved 50 people of their staff, and encouraged them to follow their advice on eco-driving for a week. Results showed that staff members saved up to 33% on their weekly fuel bills!

For the most part, the savings realised are rather in the order of 1 to 2 litres of fuel per 100 kilometres. And that’s surely more than enough to train your drivers in this economical and ecological type of driving!

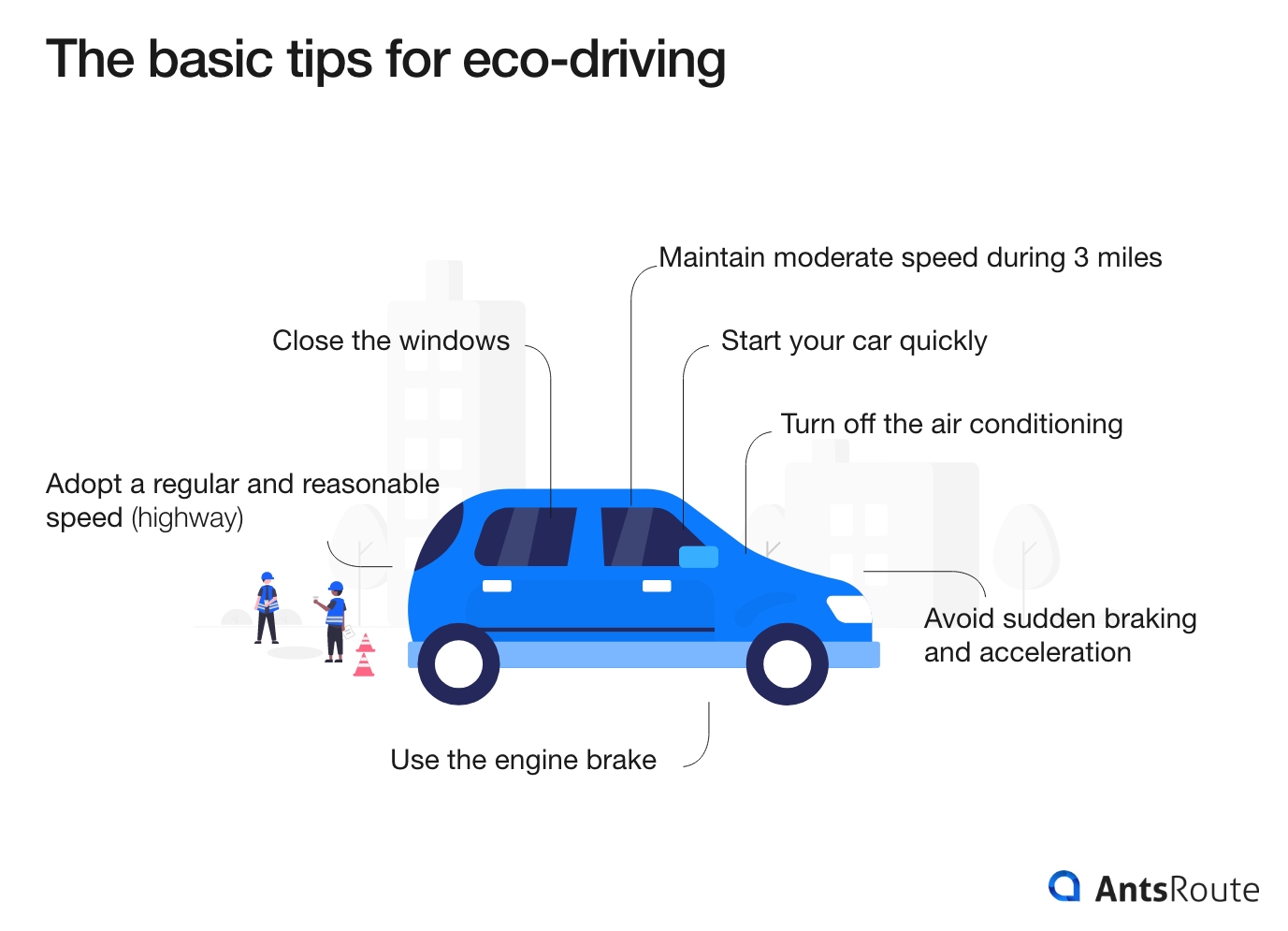

Basic tips for eco-driving

- Start your car quickly without hesitation, then swiftly switch gears to optimise the energy deployed.

- Maintain a moderate speed during the first 3 miles (ca. 5 km) because the car consumes much more fuel until the engine has reached its normal temperature.

- Anticipate as much as possible to avoid sudden braking and acceleration, which are synonymous with high fuel consumption.

- Use the engine brake rather than the brake pedal, it costs nothing!

- Drive at low revs, taking advantage of the optimum torque ranges. These are rated at approximately 2000 rpm for a diesel car, and between 2000 and 2500 rpm for a petrol car.

- On the highway, adopt a regular and reasonable speed. It is increasingly easy to drive on cruise control as it is fitted to the majority of new vehicles.

- Turn off the air conditioning as soon as possible, and never exceed more than 5 degrees difference to the outside temperature. The AC, which consumes up to 1 L per 100, remains a very energy-intensive source of comfort.

- Avoid driving with the windows open, even if the air conditioning is broken, or you are a smoker. At high speed, the lowered windows greatly affect the aerodynamics of the vehicle, forcing the car to consume more energy otherwise.

Royal Mail case study on eco-driving

Royal Mail, which estimated its fleet at 50,800 motorised vehicles in 2021, was one of the first companies to massively train its teams in eco-driving. To promote the implementation of eco-driving, it has fitted many of its vehicles with telemetry technology, in order to measure fuel consumption in real time.

Convinced by the results of the first experiments carried out in 2005 with around 13,000 large vehicles, the company has since equipped an additional 11,000 small vans to encourage fuel-efficient driving styles.

In only two years, its system has saved Royal Mail 565,000 litres of fuel, leading to a reduction of 1,440 tonnes of carbon emissions!

AntsRoute’s tips for optimised eco-driving

Although eco-driving training is more economical through online lessons in the short term, we nevertheless advise you to invest in regular face-to-face courses. This solution is often much more effective in removing the psychological brakes and actually spacing out the passages at the pump.

Truly shut off the car engine when stopped

Among the most simple tips for saving fuel, there is one that is still not followed – actually cutting the engine when stopping for more than 1 minute. This may be the case:

- In traffic jams or construction works.

- When the vehicle is stopped in double file or on the side.

- Visiting customers while waiting to load or unload a vehicle, etc…

Start and Stop type systems are precisely designed to automatically cut the engine at each stop, without damaging the mechanics. According to the Ademe (Agency for the

environment and energy management) in France, they would save between 6 and 15% fuel in the city, for petrol and diesel vehicles alike.

These systems are now fitted to many vehicles, including heavy goods vehicles. And yet, their arrival hasn’t done much to change the situation. As we all know, old habits die hard! In fact, many drivers bypass the Start and Stop:

- To turn on the heating or air conditioning.

- Waiting to be served at the wheel in front of a fast food restaurant.

- At the car wash, etc.

However, leaving the engine idling has serious consequences on fuel budgets! According to the U.S. Department of Energy, 126 litres of fuel are wasted every second in the United States by stalled trucks leaving the engine running, or more than 4 billion litres consumed for nothing each year.

Unfortunately, curbing this overconsumption is not easy. It will be necessary to show resilience and engage in a dialogue with your teams to find crafted solutions on a case-by-case basis, such as heating systems that operate with the engine off. These efforts are worth it in the long run! According to the Canadian Government, idling your engine for just 10 minutes costs 500 millilitres in wasted fuel for a 5-litre engine. Do the maths for a large international fleet of Heavy Goods Vehicles and that adds up to an impressive amount!

To save fuel, switch off the engine if you stop for more than 1 minute.

Regularly run maintenance on the fleet of vehicles

When the cash flow tightens, another well-established reflex is to ease off on maintenance expenses. To save on fuel, however, you should be doing quite the opposite! Once more, Ademe has run the maths: poor car maintenance leads to overconsumption of fuel of up to 25%.

Under-inflating your tyres by just 0.5 bar already consumes 2.4% more fuel. To save money, we recommend a slight over-inflation of 0.2 bar. Remember that tyre pressure is ideally measured every month for the first 5 kilometres before the tires heat up.

In the same way, the oil must be changed regularly, and the filters and spark plugs checked at the rate specified in the maintenance book. A clogged air filter causes combustion problems, which alone can cost you 3% more on fuel!

Finally, remember to have the alignment of the wheels checked. Poor alignment leads not only to excessive fuel consumption, but also to premature tyre wear.

Optimise driving routes

Planning delivery routes is an extremely complex operation, where many factors come into play:

- Opening hours for delivery or reception.

- Weight or volume of objects or materials transported.

- Characteristics of each vehicle (capacity, licence required, diesel engine, gasoline, electric, etc.)

- Type of action to be carried out: maintenance operation, urgent repair, collection, delivery, medical intervention, etc.

- Geographical location of the customers to be delivered to.

- Information related to the road network: recurring traffic jams, temporary works, deviations on the route, traffic bans for certain types of vehicles, etc.

Under these conditions, all it takes is an absent customer, an unforeseen detour or an incident on the road for the journey to lengthen and fuel consumption to soar!

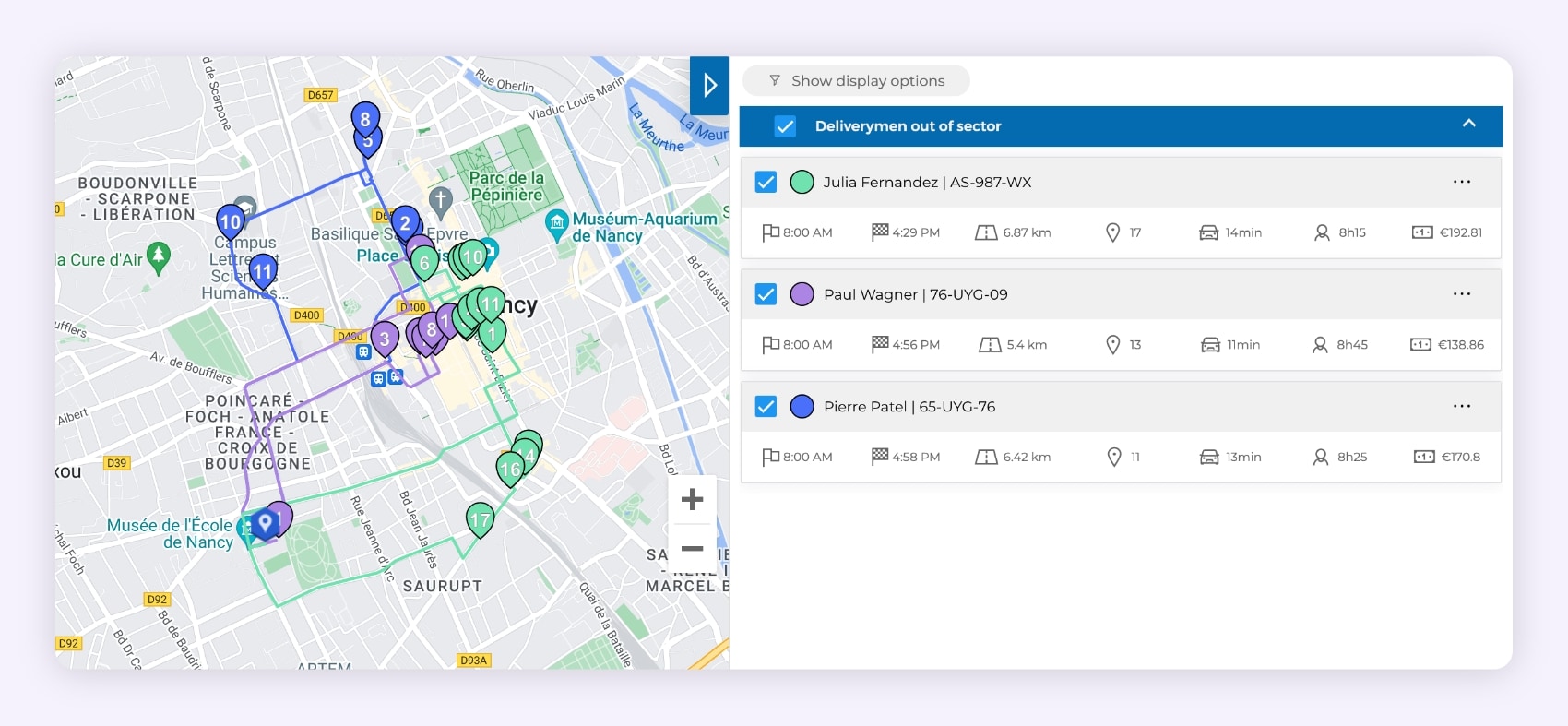

However, when required to cross-check so much data to build an effective route without surprises, spreadsheets + navigation software combinations quickly find their limits. Only route optimisation software such as AntsRoute can calculate the best routes, without unnecessary detours or loss of time.

The AntsRoute route optimisation software.

Use the right vehicle for the corresponding trip

In order to effectively reduce your fleet’s fuel consumption, another essential lever is to systematically select the best vehicle available for a given route. This can be defined as a vehicle that meets all the following conditions:

- Consume as little fuel as possible while providing the required service.

- Be able to be piloted by a driver holding the required licence and available at the time.

- Respect any traffic restrictions on the route: maximum height or weight, low emission zones, etc.

Here again, the calculations to determine the best opportunities are particularly complex.

For example, to make a large number of deliveries in a very dense city like London or Manchester, the use of several electric vehicles is sometimes more efficient than that of a heavy truck, but not always. Conversely, on long journeys in rural areas it is tempting to favour a very large diesel truck to use fewer drivers. In theory, the greater the size of a vehicle, the less the distances covered should be reduced.

But the best solution is not necessarily the most intuitive, far from it! Again, only the use of route optimisation software can save you long sessions of puzzles in front of your screen – the fuel savings will surely more than offset the price of the software subscription. This type of tool makes it possible to save up to 35% on operational costs, with an observed average of around 20%.

Increase the vehicle loading rate

Chartering an overloaded vehicle leads to overconsumption of fuel and accelerated tyre wear. But running an empty or under-filled truck is disastrous for both cash and the environment. A scientific study conducted by the International Road Transport Union had shown that a fully laden 40-tonne truck consumed “only” 10 litres more diesel per 100 kilometres compared to an empty truck, i.e. 39.2 against 29.3 litres.

To reduce these under loaded transports, and therefore optimise your fuel consumption, several additional solutions are available to you:

- Analyse your performance client by client, and renegotiate contracts that impose too much pressure on deadlines.

- Invoice additional costs or an increased price in the event of under capacity transport imposed by the customer.

- Go through a freight exchange to maximise loads or, on the contrary, subcontract certain unprofitable shipments.

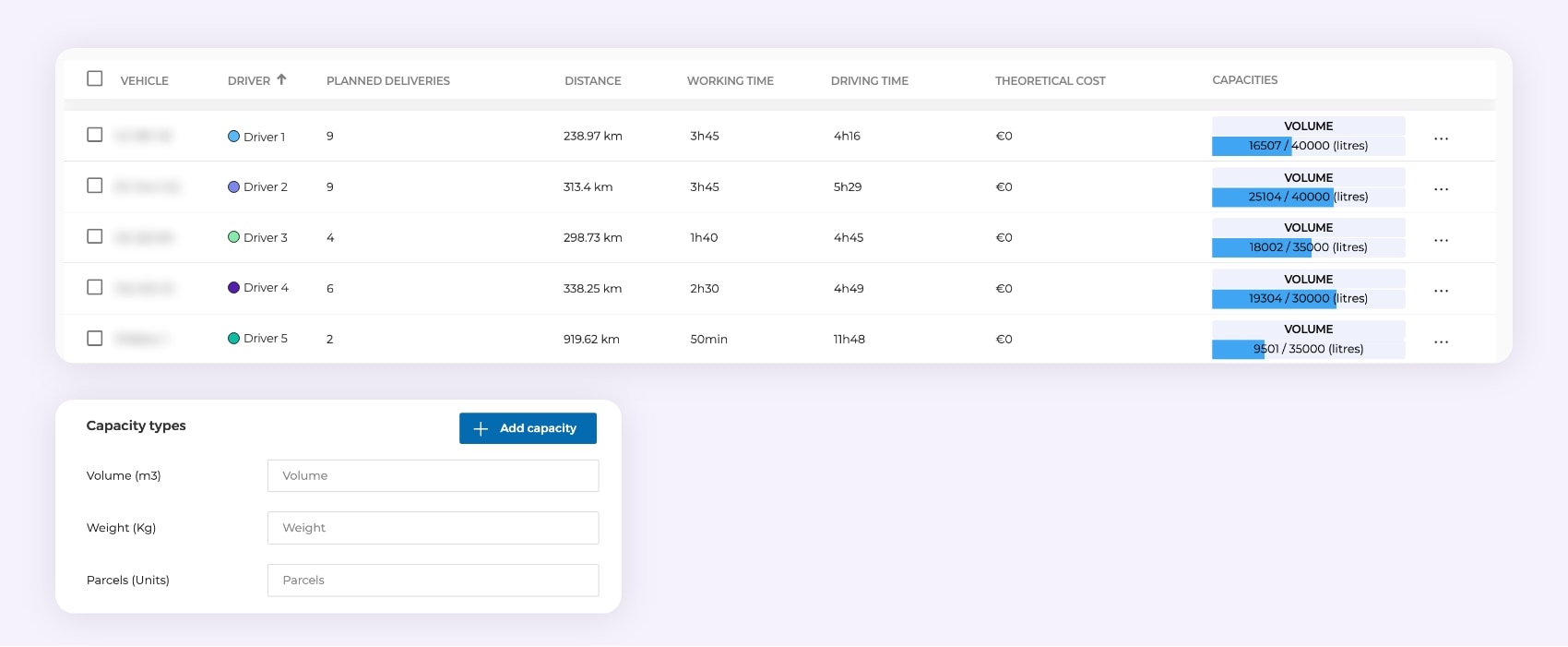

Whatever the solution is chosen, our software includes very useful functionalities to improve the loading of vehicles while respecting your constraints, such as a module for managing the capacities of your fleet, vehicle by vehicle.

The management of vehicle loading capacities with the AntsRoute tool.

Deliver in staggered hours

This last method is obviously not within the reach of all companies. But various experiments conducted in the Netherlands and France have shown that deliveries at staggered times have the effect of real energy savings and not just fuel!

During these experiments, many precautions were taken to limit nuisances, such as the use of electric machines, CNG, or vehicles respecting sound performance thresholds (trucks known as “PIEK”).

In the metropolitan area of Bordeaux, another experiment conducted with the “Déméter Environnement & Logistique” club made it possible to objectively quantify the savings linked to staggered working hours. The final report thus mentions a “reduction in fuel consumption in the event of a switch from daytime delivery to nighttime delivery […] in an order of magnitude of between 3 and 4% at full isometer”. Another significant source of savings comes from a reduction in the use of temperature-controlled trucks (positive or negative), which record significantly less consumption time when stationary. This point is all the more important since the motors that supply the cooling units “operate at a constant speed, whatever the environment and the speed of the vehicle”. A reduction in the duration of the tour, therefore, translates directly into a reduction in diesel consumption.

In general, the lesson to be learned from these different experiments is that deliveries at staggered times are less energy-intensive, thanks to the reduction in time spent on the road. If, for example, you deliver to industries that work in 2×8 or 3×8, the hypothesis of evening, early morning or weekend deliveries, therefore, deserves to be studied!

Would you like to evaluate in real conditions the fuel savings that you could achieve thanks to our route optimisation software? Go to this page to register for free and without engagement!

Free 7-day trial | No credit card required

Contenu

- Train drivers in eco-driving

- Basic tips for eco-driving

- Royal Mail case study on eco-driving

- AntsRoute’s tips for optimised eco-driving

- Truly shut off the car engine when stopped

- Regularly run maintenance on the fleet of vehicles

- Optimise driving routes

- Use the right vehicle for the corresponding trip

- Increase the vehicle loading rate

- Deliver in staggered hours